5.7 Hemi Coolant Temperature Sensor Location, Symptoms, & Replacement (Full Guide)

5.7 Hemi Coolant Sensor: The Engine’s Most Critical Thermometer

The Engine Coolant Temperature (ECT) sensor in the 5.7L Hemi engine is a small but vital component that functions as the engine’s primary thermometer. It is a “thermistor,” a two-wire resistor that varies its electrical resistance based on the temperature of the coolant.

This sensor’s role extends far beyond the temperature gauge on the dashboard. It sends its data directly to the vehicle’s main computer, the Powertrain Control Module (PCM). The PCM then uses this single data point to control some of the engine’s most critical functions, including:

- Fuel Injection: A cold engine requires a richer fuel mixture to run smoothly, while a hot engine needs less.

- Ignition Timing: The PCM adjusts spark timing based on temperature to optimize performance and prevent knock.

- Cooling Fan Operation: The sensor tells the PCM when the engine is hot enough to require the electric cooling fans to turn on.

A common point of confusion for many 5.7 Hemi owners is the sensor’s location, which is not consistent across all models. The 5.7L Hemi engine has been in production for over two decades, powering millions of Ram trucks, Dodge Chargers, Durangos, and Jeep Grand Cherokees. Over that time, its physical design has evolved.

This leads to conflicting reports: an owner of a 2014 Ram 1500 will find the sensor located conveniently by the thermostat housing, while an owner of a 2006 Dodge Durango will be told it is in a much more difficult-to-reach spot under the A/C compressor. Both reports are correct for their specific vehicles.

This guide provides a comprehensive, step-by-step process to correctly diagnose, locate, test, and replace the ECT sensor on a 5.7 Hemi engine, accounting for these critical model-year variations. For a broader overview of other potential issues with this powertrain, see our full guide on common 5.7 Hemi engine problems and their solutions.

The 5.7 Hemi Coolant Sensor

A visual guide to finding, diagnosing, and understanding your truck’s Engine Coolant Temperature (ECT) sensor.

What Does The Sensor Do?

The Engine Coolant Temperature (ECT) sensor is a small but critical component. It acts as a thermometer, sending real-time data to the engine’s main computer (ECU), which then makes vital adjustments.

1. Sensor Reads

Measures coolant temp

2. ECU Receives

Computer gets data

3. Engine Adjusts

Controls fan, fuel, & gauge

Normal Operating Range

For most 5.7 Hemi engines, the normal coolant temperature, once warmed up, should stay in this range.

(~90°C – 102°C)

Common Failure Symptoms

A failing sensor sends bad data, confusing the ECU. This can lead to a variety of issues, with some being more common than others. An active “Check Engine Light” is a primary indicator.

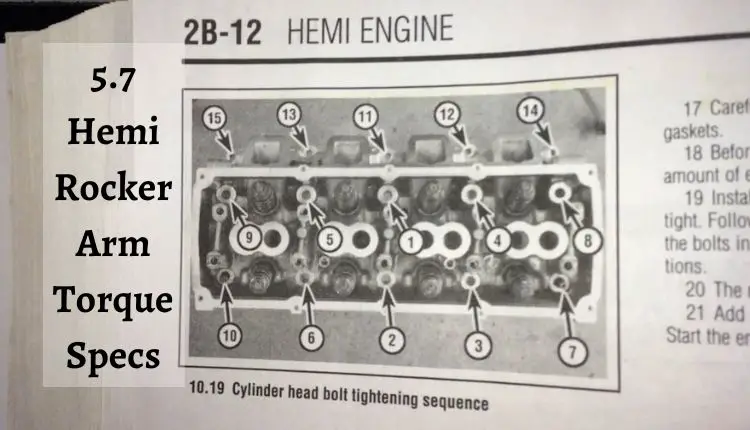

5.7 Hemi Sensor Location

This is the most common question. On most 5.7 Hemi engines (found in Ram 1500, Durango, Grand Cherokee, etc.), the sensor is located at the front of the engine, typically threaded into the thermostat housing or the water pump assembly itself. You will need to remove the plastic engine cover to see it.

Simplified Engine Front Diagram

SENSOR HERE

Usually 2-wire plug

DIY Replacement Process Overview

Replacing the sensor is a common DIY job. Always follow safety precautions and consult a vehicle-specific repair manual. Do this on a cold engine.

Safety & Prep

Park, let engine cool. Disconnect negative battery terminal.

Drain Coolant

Place drain pan. Open radiator petcock to drain coolant below sensor level.

Access Sensor

Remove engine cover and any air intake parts blocking access.

Swap Sensor

Unplug electrical connector. Use deep socket to remove old sensor. Install new sensor (don’t overtighten).

Refill & Check

Reconnect battery. Refill coolant. Start engine and check for leaks and proper gauge operation.

DIY vs. Professional Repair

This is a very manageable DIY task that can save you significant money. The part itself is inexpensive, but shop labor rates make up most of the professional cost.

| Metric | DIY (Do It Yourself) | Professional (Mechanic) |

|---|---|---|

| Average Cost | $20 – $50 (Part Only) | $150 – $300 (Parts & Labor) |

| Estimated Time | 1 – 2 Hours (Varies by skill) | 0.5 – 1 Hour (Shop time) |

| Tools Required | Basic hand tools, drain pan, deep socket set | Professional tools, diagnostic scanner |

5.7 Hemi Coolant Temperature Sensor Location (The Definitive Answer)

The ECT sensor’s location depends primarily on the vehicle’s model and generation. There are two primary locations.

Primary Location (The “Easy” Spot): By the Thermostat Housing

On most newer 5.7 Hemi engines (approximately 2009 and newer), the ECT sensor is located in the most logical and accessible place: on or near the thermostat housing.

- How to Find It: Open the hood and locate the large, thick radiator hose at the top of the radiator (the upper radiator hose). Follow this hose back to the front of the engine, where it connects to a metal housing. This is the thermostat housing. The ECT sensor is a small, two-wire sensor (typically with a plastic electrical connector) threaded directly into that housing or the intake manifold immediately beside it.

- Vehicles: This location is common on the 2009+ Ram 1500, 2009+ Dodge Charger/Chrysler 300, and Jeep Grand Cherokee (WK/WK2) models.

Secondary Location (The “Hard” Spot): Under the A/C Compressor

On many older 5.7 Hemi engines (approximately 2004-2008), particularly in SUV platforms, the sensor is in a much less accessible location.

- How to Find It: This sensor is not visible from the top of the engine bay. It is a two-wire sensor located on the passenger side of the engine block, “located under the air conditioning compressor”. Access is typically gained by removing the passenger-side front wheel and wheel-well liner, or from underneath the vehicle.

- Vehicles: This location is confirmed for the 2004-2008 Dodge Durango and is likely the same for 2003-2008 Dodge Ram trucks.

Location by Vehicle Model (Reference Table)

This table consolidates data from various repair manuals and owner forums to help identify the correct location.

| Vehicle Model & Year Range | Common ECT Sensor Location |

| Dodge Ram 1500/2500 (2009-Present) | Location 1 (Easy): By thermostat housing. |

| Dodge Ram 1500/2500 (2003-2008) | Location 2 (Hard): Under A/C compressor. |

| Dodge Durango (2004-2008) | Location 2 (Hard): Under A/C compressor. |

| Dodge Charger / Chrysler 300 (2009-Present) | Location 1 (Easy): By thermostat housing. |

| Dodge Charger / Chrysler 300 (2005-2008) | Location 1 (Easy): By thermostat housing. |

| Jeep Grand Cherokee (WK/WK2) | Location 1 (Easy): By thermostat housing. |

How to Confirm You’ve Found the Right Sensor

It is possible to confuse the Engine Coolant Temperature (ECT) sensor with the Intake Air Temperature (IAT) sensor. Both are often two-wire thermistors.

The key difference is their function and placement:

- The ECT sensor must be threaded into a metal part of the engine (block, head, or thermostat housing) where it can make direct contact with the engine coolant.

- The IAT sensor will be mounted in the plastic air-box or the plastic intake tube, where it measures the temperature of the incoming air.

Before removing the old sensor, a good practice is to compare its electrical connector to the new replacement part. If the plug shape matches, it confirms the correct component has been identified.

Symptoms: How to Know Your 5.7 Hemi ECT Sensor is Failing

A failing ECT sensor will provide false information to the PCM. This problem typically manifests in one of two ways: a “fail cold” (open circuit) or a “fail hot” (shorted circuit), each producing distinct symptoms.

Failure Mode 1: Sensor “Fails Cold” (P0118 – Circuit High)

In this scenario, the sensor circuit is open or disconnected. The PCM receives a signal of infinite resistance, which it interprets as an impossibly cold temperature, such as -40$^{\circ}\mathrm{F}$.

- Engine Overheating: Because the PCM never receives a “hot” signal, it may not command the electric cooling fans to turn on. The engine can overheat, especially in stop-and-go traffic, while the temperature gauge on the dash may ironically read “Cold”.

- Poor Fuel Economy & Black Smoke: The PCM permanently thinks the engine is “cold” and enters a rich fuel “open loop” mode, dumping excessive fuel into the cylinders. This results in terrible gas mileage and black smoke from the exhaust.

- Rough Idle: The overly rich fuel mixture can foul spark plugs, leading to a rough idle.

- Hard Starting (When Hot): When the engine is already warm, the PCM’s “cold”-start rich fuel mixture effectively floods the engine, making it difficult to restart.

Failure Mode 2: Sensor “Fails Hot” (P0117 – Circuit Low)

In this scenario, the sensor’s internal circuit or wiring is shorted to ground. The PCM reads near-zero resistance, which it interprets as an impossibly high temperature, such as 284$^{\circ}\mathrm{F}$ or more.1

- Cooling Fans Run Constantly: The PCM enters a “panic” mode, believing the engine is critically overheating. It will run the electric cooling fans at maximum speed, even when the engine is cold (e.g., immediately at startup).

- Poor Performance & Hesitation: To protect the (supposedly) overheating engine, the PCM may pull ignition timing and lean out the fuel mixture, causing sluggish performance.

- Hard Starting (When Cold): The PCM thinks the engine is already hot, so it provides too little fuel for a proper cold start, causing the engine to crank but fail to start easily.

Universal Symptoms (Any Failure)

- Check Engine Light (CEL): This is the most common and immediate symptom. The PCM will log a fault code as soon as it detects a rational or circuit-based problem with the sensor.

- Erratic or Dead Temperature Gauge: The gauge on the instrument cluster will give false readings. It may stay fixed on “C”, shoot straight to “H,” or fluctuate wildly.

Diagnostic Codes (DTCs) for Coolant Temp Issues

An OBD-II scanner is the best tool for diagnosis. However, it is crucial to interpret the codes correctly.

A Special Warning on Code P0128

Many owners will get a P0128: Coolant Temperature Below Thermostat Regulating Temperature code 20 and assume the sensor is bad. This is incorrect. This code means the engine is not warming up to its proper operating temperature (typically 195-203$^{\circ}\mathrm{F}$) fast enough. In 99% of cases, this code is caused by a stuck-open thermostat that is letting coolant flow to the radiator prematurely.21 Replacing the ECT sensor will not fix a P0128 code.

OBD-II Code Diagnostic Table

This table clarifies what the most common ECT-related codes actually mean.

| OBD-II Code | Code Definition | What It Actually Means | Most Common Cause |

| P0117 | Engine Coolant Temp Sensor 1 Circuit Low | Signal is shorted. PCM thinks engine is 280$^{\circ}\mathrm{F}$+. | Bad sensor; Shorted wiring [16, 18] |

| P0118 | Engine Coolant Temp Sensor 1 Circuit High | Signal is open. PCM thinks engine is -40$^{\circ}\mathrm{F}$. | Bad sensor; Unplugged/broken wire [16, 24] |

| P0119 | Engine Coolant Temp Sensor 1 Circuit Intermittent | Signal is erratic, jumping, or irrational. | Bad sensor; Loose/corroded wiring; Low coolant/air pockets [19, 25] |

| P0128 | Coolant Temp Below Thermostat Regulating Temp | Engine is not warming up quickly enough. | 99% of the time: A stuck-open thermostat. [20, 21, 22] |

How to Test a 5.7 Hemi ECT Sensor (DIY Guide)

Before purchasing a new part, a faulty sensor can be definitively confirmed with one of two tests.

Method 1: The Live Data Scanner Test (Easiest)

This test uses an OBD-II scanner’s “live data” function.

- Perform on a “Cold-Soaked” Engine: The vehicle must be parked overnight, so the engine is completely cold and at ambient temperature.

- View Live Data: Plug in the scanner and turn the key to the “On” (run) position without starting the engine.

- Compare ECT vs. IAT: Navigate to the live data stream and find two values: “Engine Coolant Temp (ECT)” and “Intake Air Temp (IAT).”

- Diagnosis: On a cold engine, these two temperature readings should be within 5-10 degrees of each other and the outside air temperature. If the IAT reads 70$^{\circ}\mathrm{F}$ and the ECT reads -40$^{\circ}\mathrm{F}$ (P0118) or 280$^{\circ}\mathrm{F}$ (P0117), the sensor is bad.

Method 2: The Multimeter Resistance Test (Definitive)

This test (also known as a bench test) provides a definitive pass/fail result.

- Remove the Sensor: Follow the replacement steps below to remove the ECT sensor from the engine.

- Set Multimeter: Set a multimeter to measure resistance in Ohms ($k\Omega$).

- Prepare Water Baths: Prepare a cup of ice water (near 32$^{\circ}\mathrm{F}$/0$^{\circ}\mathrm{C}$) and a pot of boiling water (near 212$^{\circ}\mathrm{F}$/100$^{\circ}\mathrm{C}$).

- Measure Resistance: Submerge the metal tip of the sensor (not the plastic connector) into the water. Touch the multimeter probes to the two metal pins inside the sensor’s connector.

- Diagnosis: Compare the readings to the expected specifications. As a Negative Temperature Coefficient (NTC) sensor, the resistance should be HIGH when cold and LOW when hot. If the readings are infinite (Open Loop / O.L.) or zero, the sensor is shorted and definitively bad.

ECT Sensor Resistance Chart (Approximate Values)

| Temperature (Approx.) | Expected Resistance (kΩ = 1,000 Ohms) | Condition |

| 32$^{\circ}\mathrm{F}$ (0$^{\circ}\mathrm{C}$) | 5.18 $k\Omega$ – 6.60 $k\Omega$ | Ice Water |

| 68$^{\circ}\mathrm{F}$ (20$^{\circ}\mathrm{C}$) | 2.27 $k\Omega$ – 2.73 $k\Omega$ | Room Temp |

| 176$^{\circ}\mathrm{F}$ (80$^{\circ}\mathrm{C}$) | 0.298 $k\Omega$ – 0.322 $k\Omega$ (or 298-322 $\Omega$) | Hot Engine |

| Data derived from service manual specifications. |

Step-by-Step 5.7 Hemi Coolant Sensor Replacement Guide

This section provides instructions for replacing the sensor in both known locations.

Tools & Parts List

The tools required change significantly based on the sensor’s location.

| Tool / Part | Location 1 (Thermostat) | Location 2 (Under A/C) |

| New ECT Sensor | Required | Required |

| Ratchet Wrench | Required | Required |

| 19mm Deep Socket | Required | Required |

| Pliers | Required | Required |

| Drain Pan | Recommended | Required |

| Fresh Coolant (Mopar OAT) | Recommended | Required |

| Serpentine Belt Tool | Not Needed | Required |

| 13mm / 15mm Sockets | Not Needed | Required (for A/C bolts) |

Official Mopar Part Numbers (Common)

Part numbers can vary. It is always best to confirm with a dealer using the vehicle’s VIN.

| Mopar Part Number | Replaces | Approx. MSRP |

| 5149077AB | 5149096AB | $49 – $67 |

| 56027873 | – | $88 – $125 |

| Aftermarket (e.g., FAE) | – | $34+ |

Replacement Steps: Location 1 (By Thermostat)

This is a beginner-level repair that takes approximately 30 minutes.

- Safety First: Park the vehicle on a level surface and wait for the engine to be completely cold to the touch. Opening a hot cooling system can cause severe burns.

- Disconnect Battery: Disconnect the negative terminal from the battery.

- Prepare for Spillage: Place a drain pan under the thermostat housing. A small amount of coolant will spill when the sensor is removed. (Optional: Partially drain the radiator via the petcock to minimize spillage).

- Remove Connector: Press the release tab on the electrical connector and pull it off the sensor.

- Remove Old Sensor: Using a 19mm deep socket, turn the sensor counter-clockwise to unscrew and remove it. Be ready to swap in the new sensor quickly to minimize coolant loss.

- Install New Sensor: Ensure the threads on the new sensor are clean (and have thread sealant if not already applied). Thread the new sensor in by hand to prevent cross-threading.

- Torque to Spec: Tighten the sensor with the socket wrench. Be careful not to overtighten. (See torque spec table below).

- Reconnect & Refill: Plug the electrical connector back in until it clicks. Top off the radiator and coolant reservoir with the correct 50/50 OAT coolant. Reconnect the battery.

Replacement Steps: Location 2 (Under A/C Compressor)

This is an advanced repair that can take 2-4 hours.

- Safety First / Disconnect Battery: Same as above. Ensure the engine is completely cold.

- Drain Coolant: This is mandatory as the sensor is low on the engine block. Place a large drain pan under the radiator and open the petcock to drain the system.

- Remove Serpentine Belt: Use a serpentine belt tensioner tool (or a long-handled ratchet) to release the tension on the belt tensioner. Slide the belt off the pulleys.

- Access Sensor: Access the passenger-side A/C compressor. Remove the 3-4 mounting bolts (typically 13mm or 15mm) that hold it to the engine block.

- Move Compressor: Do not disconnect the A/C lines. Carefully move the compressor aside (a bungee cord can help hold it) to gain access to the ECT sensor, which is located on the block behind it.

- Remove/Install Sensor: Unplug the electrical connector. Use a 19mm deep socket and extensions as needed to remove the old sensor. Install the new sensor by hand first.

- Torque to Spec: Tighten the sensor to the correct specification.

- Reassemble: Re-bolt the A/C compressor to the block. Re-install the serpentine belt (ensure it is routed correctly). Reconnect the sensor’s electrical plug.

- Refill & Bleed System: Close the radiator petcock. Slowly refill the cooling system. After refilling, the system must be properly bled to remove air pockets. For detailed instructions, follow our guide on.

Critical Data: 5.7 Hemi ECT Sensor Torque Spec

Overtightening the sensor can crack the housing or shear the sensor itself. The specified torque has varied by engine generation.

| Source | Model Year | Torque Spec (ft-lbs) | Torque Spec (Nm) |

| Service Manual 28 | General / Older | 11-15 ft-lbs | 15-20 Nm |

| Gen III Hemi Specs 37 | 2009+ Gen III Hemi | 23 ft-lbs | ~31 Nm |

| Expert Recommendation | All Models | 15 ft-lbs. (Snug, do not overtighten) |

The safest practice is to tighten the sensor to 15 ft-lbs. This is snug enough to seal without risking damage.

5.7 Hemi Coolant Sensor Replacement Cost (DIY vs. Pro)

The cost to replace the ECT sensor varies dramatically based on two factors: the sensor’s location (Location 1 vs. Location 2) and what parts are being replaced (sensor only vs. full thermostat assembly).

This explains the wild discrepancy in estimates. A mobile mechanic service may quote $167 ($72 part + $95 labor), while a service like RepairPal estimates an average of $441 – $532 ($358-$376 part + $83-$121 labor). A forum user with a vehicle where the sensor is hard to reach was quoted nearly $1,000.

Here is the breakdown of what those prices imply:

- The $450-$550 Estimate: This high parts cost ($358-$376) suggests the quote is for replacing the entire thermostat housing assembly, which includes the sensor, the thermostat, and the metal housing, as a single unit.

- The $150-$220 Estimate: This is the most realistic cost for replacing only the sensor when it is in Location 1 (by the thermostat). This reflects a $35-$90 part and 0.5 to 1.0 hour of labor.

- The $400-$1,000+ Estimate: This reflects a job where the sensor is in Location 2 (under the A/C compressor). The part is still cheap, but the labor is 3-5+ hours to remove and reinstall the compressor.

Estimated Replacement Cost Table (with Context)

| Service | DIY Cost (Parts Only) | Professional Cost (Est.) | What This Price Implies |

| Sensor Only (Location 1) | $35 – $90 | $150 – $220 | This is the most likely scenario. 0.5-1.0 hour labor. [31, 38] |

| Full Thermostat Housing | $150 – $250 | $450 – $550 | This is the RepairPal estimate. Replaces sensor, thermostat, and housing. [39, 42] |

| Sensor Only (Location 2) | $35 – $90 | $400 – $600+ | This is for older Durangos. 3-5 hours labor to R&R A/C compressor. [6, 41] |

Frequently Asked Questions (FAQ)

Q: Can I drive my 5.7 Hemi with a bad coolant temperature sensor?

A: It is strongly not recommended. A faulty sensor can fail to turn on the cooling fans, leading to engine overheating and severe internal damage. At best, the vehicle will have poor performance, bad fuel economy, and will fail an emissions test.

Q: Will a bad ECT sensor cause a no-start?

A: It can cause a hard start. If the sensor “fails hot,” it will be hard to start when the engine is cold. If it “fails cold,” it will be hard to start when the engine is warm. It does not typically cause a complete “no-crank” condition.

Q: What is the 5.7 Hemi coolant temperature sending unit location?

A: “Sending unit” or “sender” is an older term for the Engine Coolant Temperature (ECT) sensor. They are the same part, and the location is the same as described in this guide.

Q: What is the torque for the 5.7 Hemi coolant temp sensor?

A: The specification varies by model year. Older models are typically 11-15 ft-lbs, while newer (2009+) Gen III Hemi engines may be specified higher, at 23 ft-lbs.37 To be safe, tightening to 15 ft-lbs is recommended. Do not overtighten, as you can crack the housing.

Q: I have code P0128. Is my coolant sensor bad?

A: No. Code P0128 almost always means the thermostat is stuck open and the engine is not warming up properly. Replacing the sensor will not fix this code; the thermostat must be replaced.