2013-2023 Ram 1500 Problems: A Data-Driven Guide to Hemi, EcoDiesel, and Air Suspension Issues

The Ram 1500, particularly within the 2013 to 2023 model years, presents a significant contradiction to potential buyers. On one hand, it is one of the most celebrated pickup trucks of the decade. It has been lauded by critics, winning MotorTrend’s “Truck of the Year” award an impressive five times, including in 2013, 2014, 2019, and 2021 Owners consistently praise its “smooth riding” coil-spring (and air) suspension , refined interiors, and overall capability.

On the other hand, the internet is populated with owner forums documenting “lemon experiences”, catastrophic engine failures, and lists of “worst years” to avoid.

This discrepancy exists because the “2013-2023 Ram 1500” is not one single truck; it is a complex 11-year span covering two distinct generations and a third overlapping “Classic” variant. A failure on a 2019 Laramie is not the same as a failure on a 2019 “Classic,” and a potential buyer must understand these differences.

- 4th Generation (2013-2018): This is the mature phase of the “DS” platform, which originally launched in 2009. These years represent the platform after many of its initial bugs had been addressed.

- 4th Generation “Classic” (2019-2023): When the 5th Generation launched, Ram continued to produce and sell the older 4th Generation truck as a budget-friendly “Classic” model.

- 5th Generation (2019-2023): This is the all-new, redesigned “DT” platform. It introduced a new frame, a hybrid eTorque system, and the headline-grabbing 12-inch vertical Uconnect screen.

The problems and reliability profile of a 4th Gen truck are fundamentally different from those of a 5th Gen. For example, the 4th Gen is known for issues with its Totally Integrated Power Module (TIPM), while the 5th Gen is known for its 12-inch screen blacking out.

This guide will provide a deeply researched, data-driven analysis of the most common and costly 2013-2023 Ram 1500 problems. It will dissect specific, high-frequency failures by component and engine, separate anecdotal forum noise from statistical trends, and provide a clear verdict on the best and worst years to buy.

2013-2023 Ram 1500 Problems: A Visual Guide

Popular, But Not Perfect

The Ram 1500 is a top-seller, but this 10-year span covers two generations with distinct issues. This is what owners report most.

Top Complaint Categories

Owner complaints aren’t spread evenly. Engine and electrical issues, particularly the Uconnect system, dominate the reports filed for these model years.

Deep Dive: The ‘HEMI Tick’

The most infamous 5.7L HEMI issue is a ticking noise, often a precursor to costly camshaft and lifter failure. Here’s the typical progression:

Problem: ‘HEMI Tick’

A distinct tapping noise from the engine, especially at idle.

Cause: Lifter/Camshaft Failure

Hydraulic lifter roller bearings fail, damaging the camshaft lobes.

Symptom: Misfires

As damage worsens, the engine may misfire, triggering check engine lights.

Electrical & Tech Headaches

Across both generations, electrical gremlins are a major source of frustration. 4th Gen (pre-2019) trucks suffer from TIPM failures, while 5th Gen models are known for buggy Uconnect systems.

Drivetrain & Suspension

While the ZF 8-speed is generally stout, it’s not without issues. The optional air suspension is a common failure point as trucks age.

- Harsh Shifting: Often attributed to software or low fluid, but can indicate internal wear.

- Delayed Engagement: A notable pause when shifting from Park to Drive or Reverse.

- Air Suspension Leaks: Rubber airbags crack, and lines become brittle, leading to a sagging truck.

- Compressor Failure: The air compressor overworks to compensate for leaks and eventually burns out.

Body, Frame, & Rust

Structural integrity is key, but these trucks have well-known weak spots for corrosion, particularly in regions that use road salt.

- Rear Fender Rust: The area above the rear wheel wells is notorious for bubbling and rusting from the inside out.

- Cab Corners: Another moisture trap that can lead to significant rocker panel and cab corner rust.

- Exhaust Manifold Bolts: HEMI engines are prone to breaking exhaust manifold bolts, causing an exhaust leak.

- Cracked Tailgates: Some 5th Gen tailgates have shown stress cracks near the body lines.

Reliability Trend by Model Year (Complaint Volume)

This trend shows representative complaint volume. Note the higher issues in 2013-2014 (4th Gen problems), a decline as the generation matured, and another spike in 2019, the first year of the new 5th Generation, which has since declined.

Ram 1500 (2013-2023) Reliability Snapshot: Best & Worst Years

| Model Year(s) | Generation | Reliability Rating | Key Issues & Data Points |

| 2013 – 2016 | 4th Gen (Early/Mid) | Worst Years | Plagued by early-cycle bugs. Reports of engine failure (avg. 45k-78k mi, $4.3k-$11.5k cost), power steering failure (avg. 67k mi, $2.4k cost), and transmission troubles (avg. 10k mi, $10k cost).6 2013 had early ESC software recalls. |

| 2017 – 2018 | 4th Gen (Late) | Best Years | Widely regarded as the “sweet spot” for reliability. Most significant electrical and transmission issues were mitigated by 2017. The platform was mature, and most bugs had been resolved. |

| 2019 | 5th Gen (First Year) | Avoid | Listed as a “worst year”. Suffered from significant first-year redesign problems, including widespread electrical gremlins, 12-inch screen “blackouts”, and early reports of differential chattering. |

| 2020 – 2021 | 5th Gen (Mature) | Best Years | Highly awarded and praised for quality and reliability. Most of the 2019 model’s electronic and mechanical bugs were addressed. |

| 2022 – 2023 | 5th Gen (Late) | Good | Continues the high-reliability streak of 2020-2021. 2023 models are noted for their dependability. Some minor owner reports of quality control issues with fit and finish. |

Critical Engine Problems: A Breakdown by Powertrain

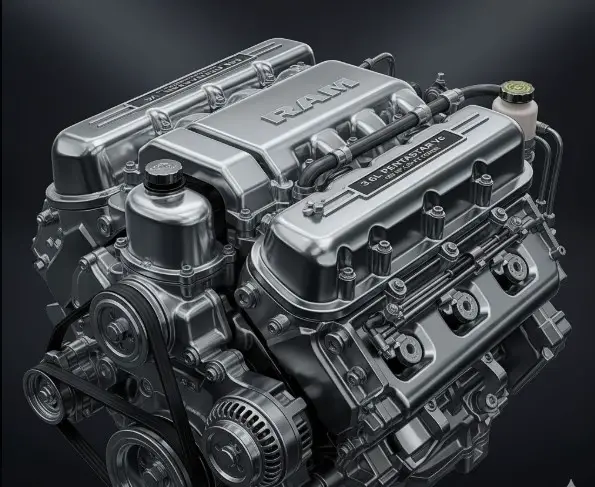

The engine is the heart of any truck and the single most significant factor in its long-term ownership cost and experience. In the 2013-2023 Ram 1500, the three main engine options—the 5.7L Hemi V8, the 3.0L EcoDiesel V6, and the 3.6L Pentastar V6—each have one signature, high-cost, and extremely well-documented flaw.

The 5.7L Hemi V8: Decoding the “Hemi Tick”

The 5.7L Hemi V8 is the most common and iconic engine choice for the Ram 1500. For the most part, it is a proven and reliable workhorse, with many owners reporting well over 100,000 miles with only routine maintenance. However, this engine is haunted by a widely discussed problem known as the “Hemi Tick.”

This term is a semantic trap, as it is commonly used to describe two mechanically unrelated problems with vastly different repair costs. One is a minor annoyance; the other is a catastrophic internal engine failure.

Problem A: The “Good” Tick (Exhaust Manifold Leak)

This is the most common and least severe cause of a ticking noise.

- Cause: The Hemi’s cylinder heads are made of iron, while the exhaust manifold bolts are made of steel. These two metals expand and contract at different rates during heat cycles. Over time, this stress causes the manifold bolts—especially the rearmost ones—to snap.

- Symptoms: A distinct “ticking” or “puffing” sound that is most pronounced on a cold start. The sound often quiets down or disappears as the engine warms up, because the expanding metal of the manifold seals the small exhaust leak.

- Fix: This is a relatively straightforward, albeit labor-intensive, repair. A mechanic must remove the exhaust manifold, extract the broken bolt (which can be difficult), and replace the bolts and manifold gasket.

Problem B: The “Bad” Tick (Camshaft & Lifter Failure)

This is the dreaded, severe, and extremely expensive “Hemi Tick.”

- Symptoms: A deeper, heavier, metallic “tick” or “knock” that sounds like it is coming from deep within the engine block, not just the side.24 This noise is persistent and may be accompanied by an engine misfire (triggering a Check Engine Light) as the failed lifter stops opening its corresponding valve.

- Cause and Failure Analysis: This is not a simple wear-and-tear issue; it is a design-induced lubrication failure. The problem is almost exclusively traced to the hydraulic roller lifters on the cylinders that are deactivated by the Multi-Displacement System (MDS).

- The MDS lifters are more complex than standard lifters. At low RPMs or, most critically, during extended periods of idling, oil pressure and flow may become insufficient to properly lubricate the needle bearings inside the lifter’s roller tip.

- When lubrication fails, the needle bearings disintegrate, and the roller seizes. It stops spinning.

- The engine’s camshaft, spinning at high speed, then grinds against the seized, stationary roller. This violent, metal-on-metal contact quickly “wipes” the cam lobe flat and destroys the lifter, sending metal particles throughout the engine.

- Contributing Factors:

- Multi-Displacement System (MDS): The failure is almost always on an MDS-controlled cylinder.

- Extended Idling: This is a major suspected culprit. Forum discussions often note that “retiree” trucks that are “babied” and idled frequently seem to fail more often than work trucks that are driven hard, which maintains higher oil pressure.

- Oil Type and Level: Using the incorrect oil (the engine specifies 5W-20), running the engine on low oil, or having aerated oil from too much oil can all starve the lifters of proper lubrication and accelerate failure.

- Prevention and Solution:

- Prevention: The best prevention is to limit engine idle time, use a high-quality full synthetic 5W-20 oil, and perform regular oil changes. Some owners proactively install an MDS-delete kit, and some reports suggest using 5W-30 oil provides a thicker, more durable oil film, though this is debated.

- Fix: This is a massive repair. It requires the engine to be significantly disassembled to replace the entire camshaft, all 16 lifters (not just the failed one), and often the oil pump. The cost is significant, with some 2013 models reporting engine failure repairs at $11,500.

For a technical deep-dive, see this guide on Hemi lifter failure causes. Following a strict maintenance schedule is key. See our(https://truckguider.com/5-7-hemi-maintenance-tips).

The 3.0L EcoDiesel V6: A Pattern of Critical Failures

The 3.0L EcoDiesel (available from 2014-2023, with a Gen 1 and Gen 2 design) was heavily marketed for its class-leading fuel economy and impressive torque. However, the Gen 1 and Gen 2 (2014-2019) engines have proven to be one of the most problematic powertrains in the entire Ram lineup.

This is not a simple “reliability” problem; it is a documented safety and legal liability. The engine’s primary flaw is so severe that it has triggered massive recalls and a major class-action lawsuit due to a significant vehicle fire risk.

Problem A: EGR Cooler Failure (Fire Risk)

This is the most widespread and dangerous EcoDiesel problem.

- Affected Years: 2014-2019 Ram 1500 and 1500 Classic models.

- The Defect: The Exhaust Gas Recirculation (EGR) cooler is prone to developing microscopic cracks due to thermal fatigue (repeated heating and cooling).

- The Consequence: These cracks allow engine coolant to leak into the intake system. This coolant can then be combusted in the engine, which creates a “potential for engine fire”. There were reports of minor injuries from owners attempting to extinguish these fires themselves.

- The Fix: This defect was the subject of a massive recall for 160,000 trucks worldwide (FCA recall numbers U74/V44).29 It also led to the class-action lawsuit Crawford v. FCA US LLC, which resulted in a settlement providing an extended warranty on the replacement EGR cooler and reimbursement for related costs. Any potential buyer of a 2014-2019 EcoDiesel MUST verify this recall work has been performed.

Problem B: Oil Cooler Failure

- Affected Years: Primarily 2014-2016 models.

- The Defect: The engine’s oil cooler, particularly when subjected to heavy towing or mountain driving, is a known weak point and can fail.

- Symptoms: When it fails, the oil cooler allows oil and coolant to mix. This will contaminate the entire cooling system (look for black, oily sludge in the coolant reservoir) and can quickly lead to engine overheating and catastrophic damage if not addressed.

Problem C: High-Pressure Fuel Pump (HPFP) Failure

- The Defect: Like many modern diesel engines, the EcoDiesel’s HPFP (High-Pressure Fuel Pump) can fail. When it does, it often disintegrates internally, sending tiny metal fragments throughout the entire high-pressure fuel system.

- The Fix: This is one of the most expensive repairs possible on a diesel. It is not enough to just replace the pump; the metal fragments have contaminated the fuel lines, fuel rails, and all six fuel injectors. The entire system must be replaced, a repair that can easily exceed $10,000.

The 3.6L Pentastar V6: The “When, Not If” Oil Leak

The 3.6L Pentastar V6 is the standard base engine for the Ram 1500. It is generally considered a very reliable and low-maintenance engine… with one major, guaranteed exception.

The Defect: Cracking Plastic Oil Filter Housing / Cooler Assembly

- Affected Years: All Ram 1500 trucks equipped with the 3.6L V6 from 2012-present.

- Failure Analysis: This is a “when, not if” failure. The problem is a “serious flaw in the design”.The entire oil filter and oil cooler assembly is made of plastic and sits deep in the “V” of the engine valley, directly under the intake manifold.35

- This location subjects the plastic component to constant, extreme heat cycles.

- Over time, the plastic becomes brittle and warps, and the o-rings and gaskets shrink and harden.

- This inevitably leads to cracks in the housing or failed seals, causing a significant oil and/or coolant leak.The number of complaints is described as “staggering,” and even OEM replacements are known to fail again.

- Symptoms:

- A strong smell of burning oil after the truck is driven, as the leaking oil drips onto hot engine and exhaust components.

- Oil pooling in the engine valley, which then flows down the back of the engine and drips from the transmission bell housing.35 This is very often misdiagnosed as a much larger and more expensive rear main seal leak.

- The Fix: The good news is that this problem is manageable and has a permanent solution.

- Bad Fix: Replacing the failed part with another OEM plastic unit, which is doomed to fail again.

- Good Fix: Replacing the failed unit with a redesigned, aftermarket aluminum housing (such as the Dorman 926-876 mentioned by mechanics).The aluminum part is not susceptible to heat warping and cracking, permanently solving the design flaw. The repair typically costs between $500 and $1,000.

Ram 1500 Engine Problems (2013-2023): A Comparison

| Engine | Primary Failure | Symptoms | Est. Repair Cost | Nature of Flaw |

| 5.7L Hemi V8 | Camshaft/Lifter Failure | Ticking, misfires, engine knock | $4,000 – $11,500 | Design/Lubrication |

| 3.0L EcoDiesel V6 | EGR Cooler Cracking | Coolant loss, smoke, Fire Risk | $2,500+ (Often Recall/Warranty) | Design/Thermal Fatigue |

| 3.6L Pentastar V6 | Oil Filter Housing Cracking | Oil smell, oil in engine valley | $500 – $1,000 | Material/Design |

Common Drivetrain, Suspension, and Electrical Problems

Beyond the engine, a few other high-cost systems are known problem areas. These issues can range from minor annoyances to repairs costing thousands of dollars, and they are critical factors in the total cost of ownership.

ZF 8-Speed Transmission Faults (2013+)

The 8-speed automatic transmission (a ZF-designed 8HP70 unit) was a major upgrade for the Ram 1500 in 2013, offering better performance and fuel economy. It is generally well-regarded by owners and mechanics, especially when compared to the problematic 8-speed transmissions used by competitors like GM.

However, this transmission is not flawless. It is a complex, fully electronic unit with specific, known internal weak links that have been identified by transmission repair specialists.

- Common Symptoms:

- Hard, jerky, or delayed shifts.

- Slipping between gears, where the engine RPMs flare without acceleration.

- Significant hesitation during gear changes.

- Clunking, whining, or grinding noises during acceleration or shifting.

- Known Internal Failures:

- A-Clutch Pressure Plate Failure: This is a common failure point. The A-clutch pressure plate is a thin, stamped-steel component that is prone to bending, cracking, or breaking under pressure.

- E-Clutch Hub Spline Failure: The on the E-clutch hub, which are responsible for engaging the ring gear, can wear out or strip completely, especially under heavy loads.

- Valve Body & Solenoid Issues: As a fully electronic transmission, its “brain” is the valve body. This complex component is prone to wear, which can cause hydraulic pressure leaks. Failed solenoids can also lead to delayed shift engagement and gear ratio error codes.

- Non-Mechanical Causes: It is critical to note that not all shifting issues are mechanical. These transmissions are highly sensitive to electronics. A failing battery, low voltage, a faulty transmission sensor, or even outdated software can all cause erratic and harsh shifting.

Air Suspension Failures:

A High-Priced ProblemThe optional 4-corner air suspension is responsible for the Ram 1500’s “exemplary ride” 42 and offers adjustable ride height. However, from a long-term ownership perspective, it is arguably the single most high-risk and expensive feature on the truck.

The system is complex, relying on air springs (bags), air lines, sensors, a central compressor, and a valve block to manage airflow.43 This complexity creates multiple points of failure, turning the truck into a “money pit” for many owners.45

- Common Failure Points:

- Air Leaks: This is the most common problem. The rubber air springs or plastic air lines can develop leaks from punctures, age, or wear.The primary symptom is the truck “sagging” in one or more corners, especially after being parked overnight.

- Compressor Failure: A leak in the system causes the air compressor to run constantly to try and maintain ride height. This overwork burns out the compressor motor. A loud, noisy compressor is a key warning sign of its impending failure.Compressors also fail from moisture ingestion, which corrodes its internal parts.

- Valve Block Failure: The valve block directs air to the four corners. It can fail due to moisture, debris from a failing compressor, or electronic issues.

- Cold Weather Malfunction: These systems are notoriously problematic in cold climates. Any moisture in the air lines or compressor can freeze, causing components to become brittle, crack, or fail to operate entirely.

- Buyer’s Verdict: This is a high-cost, high-risk feature. A single repair can average $2,000. However, the failures often cascade. A case study from one 2013 Ram owner detailed a repair journey totaling approximately $6,900 ($2,500 + $1,200 + $3,200) over three separate incidents. The final $3,200 payment was to remove the entire air suspension system and convert the truck to a standard, reliable coil spring setup. Unless an iron-clad extended warranty is in place, buyers on a budget should actively seek a truck with the standard coil springs.

Infotainment & Electrical Glitches

Electrical problems in the 2013-2023 Ram 1500 are highly specific to the truck’s generation and trim level. A buyer does not just “look for electrical bugs”; they look for specific, predictable bugs based on the model they are inspecting.

Problem A: 4th Gen (2013-2017) TIPM Failure

- What it is: The Totally Integrated Power Module (TIPM) is the truck’s main fuse box and central electrical hub, controlling everything from the fuel pump to the power windows.

- The Defect: This module, used in 2009-2017 models, is infamous for failing, often due to internal corrosion or moisture ingress.

- Symptoms: The symptoms are “electrical chaos.” The fuel pump may continue to run after the truck is off, draining the battery. The power windows may roll down on their own. The horn, wipers, and door locks may activate randomly, making the truck seem possessed.

Problem B: 8.4″ Uconnect Screen Delamination (2017-2023)

- The Defect: This problem affects the popular 8.4-inch Uconnect screen found in late 4th Gen and most 5th Gen trucks. The adhesive gel separating the top glass digitizer (the touch layer) from the underlying LCD screen fails. This causes the layers to separate, creating large, unsightly “bubbles”.

- Symptoms:

- “Ghost Touching”: The delamination causes the screen to register random, phantom touches. This can be infuriating and dangerous, as the system will start making random phone calls, changing climate control settings, or switching radio stations.

- Cosmetic Defect: The screen looks like it has a large, growing bubble, which is unsightly.

- The Fix:

- Dealer Fix: A dealer will not repair the screen. They will replace the entire Uconnect head unit, a repair that costs between $1,200 and $3,400.

- DIY / 3rd-Party Fix: The unit itself is not broken, only the screen. The digitizer/LCD assembly can be purchased online and replaced, a common DIY fix.

Problem C: 5th Gen 12″ Uconnect “Black Screen of Death” (2019+)

- The Defect: The large, 12-inch vertical screen (a hallmark of the 5th Gen) suffers from a different set of problems. It is prone to intermittently flickering, freezing, or going completely black.

- Symptoms: A total loss of infotainment, climate controls, and, critically, the backup camera. The screen may be black for days and then randomly start working again.

- The Fix: This has been an elusive problem for owners.

- Soft Reset: Holding the volume and tune buttons for 10 seconds can sometimes reboot the system.

- Hard Reset: Disconnecting the truck’s battery for several minutes will force a full reset.

- Battery Voltage: These trucks are extremely sensitive to voltage. A weak or dying battery is a common cause of these screen blackouts.

- Dealer Fix: If resets fail, the unit likely needs a critical software update or a complete replacement of the “radio brain” (head unit), which is a costly repair.

Problem Spotlight: 4th Gen (2013-18) vs. 5th Gen (2019-23) Reliability

A potential buyer’s most important decision is which generation to buy. The problems are not the same, and the “best” and “worst” years are clustered around the 2019 generational change.

4th Generation (2013-2018) & “Classic” (2019+)

- The Good: This is a highly mature and proven platform. By 2017-2018, nearly all of the significant drivetrain and electrical bugs had been resolved. These final years of the 4th Gen are widely considered the “best years” and “sweet spot” for reliability. They are known for their solid 5.7L Hemi (with the lifter caveat) and the robust, well-sorted 8-speed transmission.

- The Bad: As these trucks age, they are prone to specific, predictable failures.

- 2013-2016: These early/mid-cycle years are on “worst year” lists and should be approached with caution. They had higher rates of transmission, engine, and power steering failures.

- All Years: All 4th Gens are susceptible to age-related issues like the “Hemi tick” (both kinds), air suspension failures , and 8.4-inch screen delamination.

- 2013-2017: These models use the problematic TIPM module.

5th Generation (2019-2023)

- The Good: The 5th Gen “DT” truck was a massive leap forward in interior quality, technology, and ride comfort. After a rocky first year, the 2020 and 2021 model years are highly awarded and are considered very reliable.

- The Bad: The 2019 model year is a “worst year” and should be avoided. It suffered from a long list of first-year redesign bugs.

- Key Problems: The primary issues to watch for on a 5th Gen are:

- The 12-inch “Black Screen of Death”.

- Driveshaft “clunking” or “binding” on initial startup.

- Rear differential chattering at low-speed turns, which may require a fluid and additive service.

- Continued susceptibility to Hemi lifter failure and 8.4-inch screen delamination.

This data reveals a clear and actionable buying strategy: avoid the first model year of any redesign. The “worst” years are 2013 (early 4th Gen) and 2019 (first-year 5th Gen). The “sweet spot” for reliability is found at the end of a generation (2017-2018) or after the first-year bugs have been fixed (2020-2021).

Safety Recalls & Overall Reliability Ratings

The Contradiction: Horrifying Stories vs. Excellent Data

This analysis presents a sharp contradiction. The forums and specific failure reports are filled with severe, high-cost failures: $11,500 engine replacements, $10,000 transmission troubles, $7,000 suspension repair cycles, and engine fire risks.29 This paints a picture of a “lemon” truck.

However, large-scale statistical data from independent automotive repair aggregators tells the opposite story. RepairPal, for example, gives the Ram 1500 a 3.5 out of 5.0 reliability rating, which it ranks as 1st out of 17 fullsize trucks.

This data also shows:

- Annual Repair Cost: $691. This is lower than the class average of $936 for fullsize trucks.

- Repair Frequency: 0.2 unscheduled repairs per year. This is less frequent than the class average of 0.3.

- Repair Severity: 13% probability of a repair being “severe,” which is lower than the 18% class average.

Both realities are true. The Ram 1500 is a “high-variance” truck. As one owner notes, “99% of trucks… never have problems, the 1% yell and scream”. The average owner has a statistically reliable, low-cost experience. However, the unlucky owners—often those with high-risk configurations like the 3.0L EcoDiesel or the air suspension—experience catastrophic, multi-thousand-dollar failures that dominate forums.

The key to buying a reliable Ram 1500 is to know and avoid the specific configurations that land you in that unlucky “1%.”

Critical NHTSA Recalls and Investigations

Beyond common component failures, several formal safety recalls and investigations from the National Highway Traffic Safety Administration (NHTSA) represent significant safety risks. All owners and potential buyers should check their truck’s 17-digit VIN for free at(https://www.nhtsa.gov/recalls).

Critical Ram 1500 Safety Recalls & Investigations (2013-2023)

| Affected Years | Component | The Problem | NHTSA / FCA ID |

| 2013-2018 | Brake Transmission Shift Interlock (BTSI) | The BTSI pin can stick open, allowing the truck to be shifted out of ‘PARK’ without the brake pedal being pressed, causing a rollaway risk. A 2025 NHTSA investigation is reviewing if the original recall fix was even effective, following six reports of injury after the recall was performed. | NHTSA Investigation (2025); Orig. Recalls 17V-821, 18V-100 |

| 2014-2019 | 3.0L EcoDiesel EGR Cooler | The EGR cooler can crack, leak engine coolant, and cause a vehicle fire. | FCA Recalls U74, V44 |

| 2019-2024 | Airbag Connector | The driver’s side airbag connector may be unsecured, which can prevent the airbag from deploying in a crash. | Recall 25V298000 (FCA 08C) |

| 2019, 2021-2024 | ABS Control Module | A software error in the ABS control module can disable the Electronic Stability Control (ESC) and ABS systems, increasing crash risk. | Recall 24V653000 (FCA 85B) |

Conclusion: Final Verdict and Buyer’s Guide

The 2013-2023 Ram 1500 is a class-leading truck in comfort, design, and, according to aggregate data, average reliability. The key to a positive ownership experience is to avoid the specific, known configurations that carry a high risk of catastrophic, high-cost component failures.

Final Actionable Verdict:

- On Engines:

- Reliability Winner: The 3.6L Pentastar V6 is the most reliable and lowest-cost-of-ownership choice, on the condition that the owner is prepared for the “when, not if” failure of the plastic oil filter housing. Proactively replacing this part with an aftermarket aluminum housing ($500-$1,000) makes this engine nearly bulletproof.

- Most Common Choice: The 5.7L Hemi V8 is a powerful and generally solid workhorse. Buyers must be vigilant about the “Hemi Tick.” Use high-quality synthetic 5W-20 oil, never extend oil change intervals, and avoid excessive idling to protect the lifters.

- Avoid: The 3.0L EcoDiesel V6 (2014-2019) should be avoided by almost all used truck buyers. The documented, widespread EGR fire risk, combined with other systemic, high-cost failures (HPFP, oil cooler), makes it a poor risk that negates its fuel economy benefits.

- On Features:

- Avoid the Active-Level Air Suspension. The ride comfort is not worth the long-term financial liability. The system is prone to a “money pit” cycle of cascading failures. The standard coil spring suspension is excellent and exceptionally reliable.

- On Model Years (The “Sweet Spot” Strategy):

- Your best bet for a reliable used Ram 1500 is the 2017-2018 4th Generation or the 2020-2021 5th Generation.1

- Avoid the 2013-2016 models and, most importantly, the first-year 2019 redesign, as they carry the highest risk and number of complaints.

Frequently Asked Questions (FAQs)

Q: What is the “Hemi tick” on a Ram 1500?

A: The “Hemi tick” is a common term that refers to two very different problems. The most common and least severe is a light ticking from broken exhaust manifold bolts, which is noisy but not dangerous. The second, more severe “tick” is a deep, metallic knock from a failed internal lifter and a damaged camshaft. This is a catastrophic, multi-thousand-dollar engine repair.

Q: What are the worst years for the Ram 1500 to buy?

A: Based on owner complaint data and repair statistics, the worst years to buy are 2013, 2014, 2015, 2016, and 2019. These years suffer from a high incidence of serious engine, transmission, and electrical failures. The 2019 model is particularly problematic as it was the first year of a new generation.

Q: Is the Ram 1500 EcoDiesel reliable?

A: No. The 2014-2019 3.0L EcoDiesel V6 is widely considered unreliable. It was the subject of a major NHTSA recall for a defective EGR cooler that could crack and cause a vehicle fire. It also suffers from other extremely expensive failures, including the oil cooler and the high-pressure fuel pump.

Q: How much does it cost to fix the Ram 1500 air suspension?

A: Repairs are notoriously expensive. A single component failure, like a new compressor or air spring, can cost around $2,000. The system is prone to cascading failures, where a leak leads to a burned-out compressor. One 2013 owner reported spending $6,900 over several years before finally paying to have the entire system removed and converted to standard coil springs.

Q: Is the 5.7L Hemi or the 3.0L EcoDiesel more reliable?

A: The 5.7L Hemi is significantly more reliable than the 2014-2019 3.0L EcoDiesel. While the Hemi has a known (and expensive) lifter/camshaft flaw, the EcoDiesel has multiple, systemic, high-cost failures, including a documented fire risk from its EGR cooler.