3800 Series 2 Torque Specs

The 3800 Series 2 Torque Specs include the following: cylinder head bolts – 95 ft-lbs, intake manifold bolts – 25 ft-lbs, exhaust manifold nuts – 20 ft-lbs, oil filter adapter mounting bolt – 19 ft-lbs and crankshaft pulley/harmonic balancer bolt (3.8L) – 75 to 80 ft-lbs. When replacing these components it is important to use a torque wrench to ensure that you are applying the correct amount of torque for each component. Over tightening can cause damage to internal engine parts and under tightening can lead to leaks or other problems.

It is also important when reinstalling any components that were removed during service work or repairs that all original hardware be reused if possible as different replacement hardware may require different torque specs than what was originally used in production.

If you’re looking for reliable torque specs on the 3800 Series 2 engine, your search is over. This popular motor from General Motors has impressive power and performance thanks to its 4.3L V6 engine. It can generate up to 180 horsepower and 210 lb-ft of torque, meaning it’s perfect for a range of applications including powering cars, trucks, boats and more.

To ensure that your vehicle is running at its best with this powerful motor, it’s important to be aware of the correct torque specs for the 3800 Series 2 engine before making any repairs or replacements.

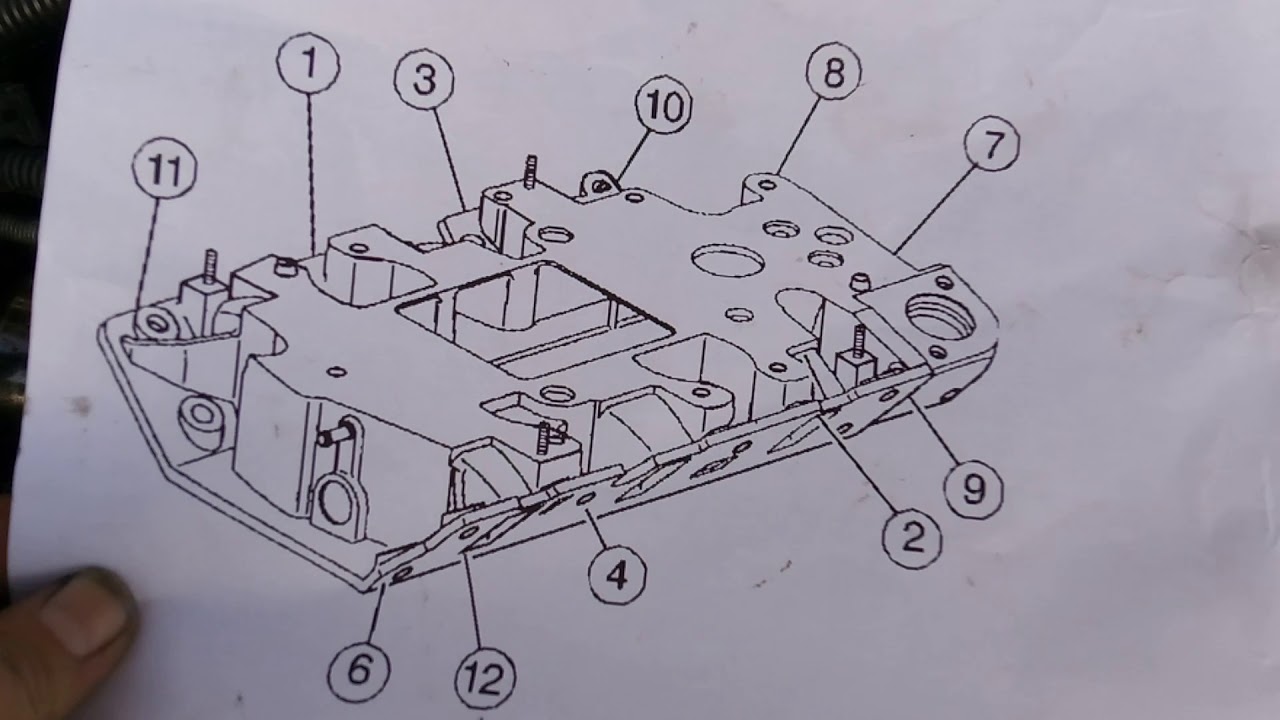

GM 3.8 engine torque specs. VERY HELPFUL.

What is the Torque Spec for the Gm 3800 Flywheel?

The torque specification for the GM 3800 flywheel is 80-100 ft/lbs. It’s important to ensure that the bolts are tightened properly in order to prevent damage or failure of components in the engine bay. To achieve this, it is recommended that you use a torque wrench and check each bolt individually against its specified value (in this case, 80-100 ft/lbs).

Taking your time when tightening these bolts will help ensure proper performance and reduce potential failure risks associated with using too much or too little force when installing them. Additionally, make sure to coat all threads prior to installation and tighten them gradually while alternating between adjacent bolts on opposite sides until they reach their desired torque spec. Doing so can help create a more even distribution of clamping force which helps preserve gaskets and other components within the engine bay over time.

What’S the Difference between a 3800 Series 2 And Series 3?

The 3800 Series 2 and 3 are two different versions of the same engine, with some major differences. The most visible difference between them is in the design – while both feature a V6 aluminum block, the 3800 Series 3 has an integrated cylinder head gasket that improves cooling efficiency and reduces emissions. Additionally, the Series 3 features improved performance thanks to its larger bore size (3.890 inches on the intake side) and higher compression ratio (9:1).

Finally, improved strength was achieved via better connecting rods and crankshaft designs as well as a higher-flow oil pump.

In terms of power output, there isn’t much of a difference between these engines; however, due to their design improvements, they can reach peak torque earlier than previous models for better acceleration off the line. This makes them ideal for vehicles that require quick response times such as police or emergency services cars or sports cars looking for more power from smaller displacement engines.

Furthermore, all these improvements allowed GM to reduce fuel consumption by up to 5% when compared to its predecessors and make it even more efficient than before!

What is the Torque on a 3 8 Grade 8 Bolt?

The torque on a 3 8 Grade 8 bolt is the amount of force that needs to be applied to secure it and prevent it from becoming loose. This type of bolt has an increased tensile strength compared to other bolts, making it ideal for use in high-pressure applications such as engine components, automotive transmissions, and machinery. The torque rating for this particular bolt is typically found stamped directly onto its head or printed in industry standard books.

When tightening the nut or washer against the bolt head with a wrench, care must be taken not to exceed the recommended torque value as over-tightening can cause damage to both the fastener and whatever surface they are securing. To ensure proper installation of your Grade 8 Bolt, always consult manufacturer instructions or contact technical support prior to installation if you have any questions about what size wrenches or sockets should be used as well as how many turns/degrees should be done when torquing down the nut or washer against the bolt head.

Is the 3800 Series 2 a Good Engine?

The 3800 Series 2 is a popular engine, and for good reason. This reliable workhorse has been powering cars since the 1990s, so it’s no wonder why many people are still using it today. The 3800 Series 2 offers excellent power and torque that can handle even the toughest jobs with ease.

It also provides great fuel economy, making it a great choice for those who want to save on gas costs without sacrificing performance. On top of all this, the engine is relatively inexpensive compared to other engines in its class, making it an attractive option for budget-conscious car owners as well. All in all, if you’re looking for an affordable yet reliable engine that won’t break your bank account or put undue strain on your wallet then the 3800 Series 2 is definitely worth considering!

Credit: www.youtube.com

Gm 3800 Head Bolt Torque Specs

The GM 3800 engine is a popular choice for many vehicles. The head bolts on these engines require a specific torque setting when they are tightened to ensure proper sealing and performance. The recommended torque specs for the GM 3800 head bolts are 30-34 ft/lbs, using either an oiled or dry thread lubricant.

It’s important to use the correct torque setting in order to ensure that your engine runs properly and doesn’t experience any leaks or other issues.

Gm 3800 Upper Intake Manifold Torque Specs

The General Motors 3800 upper intake manifold requires specific torque specs when replacing or installing it. The bolts should be tightened to 10-12 foot pounds of torque, while the nuts should be tightened to 18-20 foot pounds of torque. It is important to ensure that all connections are properly sealed and torqued as this will help prevent costly repairs in the future.

3800 Harmonic Balancer Bolt Torque

The torque specification for a 3800 Harmonic Balancer bolt is 40 to 45 ft-lbs. It is important to use the proper torque when installing this component, as an improperly tightened bolt can cause serious damage to the engine. Make sure you have the right tools and follow all instructions carefully when tackling this job!

Conclusion

In conclusion, the 3800 Series 2 Torque Specs are an important tool for anyone who needs to ensure their vehicle is running at its best. Knowing the torque specs of your engine can help you maintain it properly and avoid costly repairs or breakdowns in the future. Use these specifications to make sure that your car is running as smoothly and reliably as possible.