5.3 Ls Head Torque Specs

The torque specifications for a 5.3L head is dependent on the type of bolts and fasteners used. If using metric-sized bolts, the specification should be 118 Nm (87 lb.-ft.) plus an additional 90 degrees of rotation with a torque angle gauge. When using SAE-sized bolts and fasteners, the specification should be 86 lb.

-ft. plus an additional 90 degrees of rotation with a torque angle gauge. It is important to use a quality lubricant when tightening these components, such as motor oil or assembly lube, to prevent galling or thread damage during installation and ensure that proper tightness has been achieved according to factory specs.

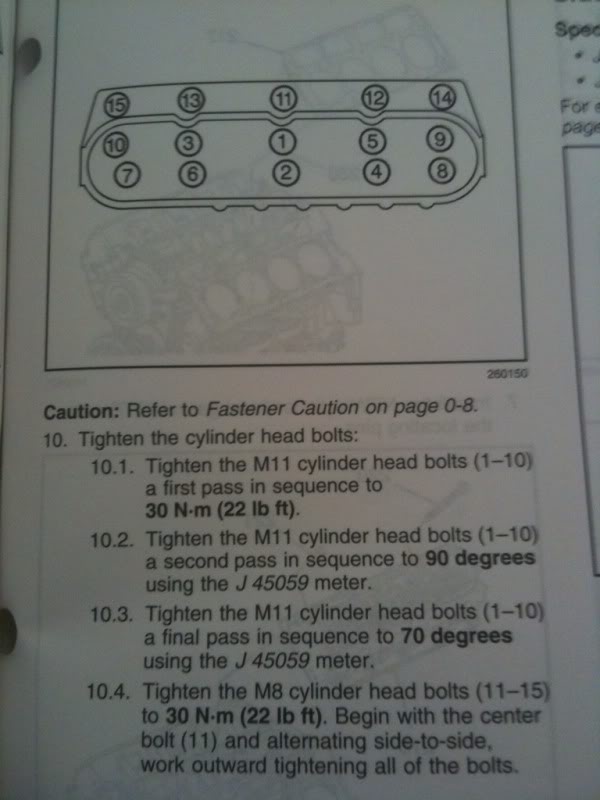

Knowing the proper torque specs for a 5.3 L head can be critical when performing engine repairs or rebuilds. Properly torquing the head bolts is essential to ensure a secure connection and prevent any damage that could occur from loose connections or excessive pressure. The recommended torque spec for a 5.3 L head is 30-35 ft/lbs, using an angle of 15 degrees while tightening each bolt in sequence as specified by your vehicle’s manufacturer.

It’s important to note that these are only guidelines, so always consult your service manual before beginning any repair work on your vehicle’s engine!

LS HEAD TORQUE SPECS / SEQUENCE for 4.8 5.3 5.7 6.0 6.2 7.0 ls1 ls2 ls3 ls6

What is the Torque Specs for Ls Head Bolts?

The torque for LS head bolts is critical to ensure a secure and leak-free seal between the cylinder heads and engine block. The correct torque setting will depend on which LS engine you are using, as some engines may require different torque settings than others. Generally speaking, most small-block LS engines require 18 ft/lbs of torque for the head bolts when using ARP brand fasteners.

If using OEM or other aftermarket fasteners, it is best to consult the manufacturer’s specifications for proper installation instructions. Additionally, all bolts should be lubricated with oil prior to installation in order to prevent thread damage during tightening. Following these guidelines will help ensure that your LS engine is sealed properly and performs at its optimal level.

What is the Torque Specs on a Ls Engine?

Torque specs for a LS engine vary depending on the individual components. Generally, you should follow the manufacturer’s specifications when it comes to torqueing down bolts and other fasteners on your LS engine. For example, most stock GM cylinder heads require 40 ft-lbs of torque for their rocker arm nuts and 8mm bolts.

The intake manifold requires 16 ft-lbs of torque for its 12mm bolts, while the throttle body requires 18 ft-lbs for its 10mm screws. It’s important to note that these values can change depending on aftermarket parts like headers or gaskets; always make sure you refer back to the manufacturer’s instructions if in doubt! Additionally, some types of fastener may require different amounts of torque than others; pay close attention when tightening these down as using too much force could result in damage to both your engine and yourself!

How Much Does It Cost to Torque Ls Heads?

The cost of torqueing LS heads varies depending on the type of engine being used and the complexity of the job. Generally speaking, it may cost between $150 to $400 for a basic torquing service. This price includes an initial inspection, cleaning, gasket installation and re-torqueing of all head bolts using a digital torque wrench.

If your engine has more complicated modifications such as port work or an extensive camshaft upgrade then you may need to spend upwards of $600-$1,000 for this service. It is important to note that in most cases it’s best to hire a professional mechanic rather than attempting this task yourself due to the risk associated with incorrectly torqued head bolts. Additionally, many performance shops offer discounts for multiple services performed at once so if you’re planning on performing additional upgrades along with your head bolt torque service be sure to ask about bundle deals before committing!

How Much Torque Does a 5.3 Vortec Have?

The 5.3 Vortec engine is a popular choice among truck and SUV owners due to its rugged power, reliability, and performance. It provides plenty of torque for all kinds of applications, from towing heavy loads or hauling the family around town. But just how much torque does the 5.3 Vortec have?

The answer may surprise you — this engine produces up to 380 lb-ft of torque at 4200 RPMs! This makes it one of the most powerful engines in its class, capable of providing enough grunt for even heavier duties like pulling trailers or boats with ease. Not only that but it also has an impressive fuel economy rating when compared to other similar engines on the market today, making it an economical choice as well.

All in all, if you’re looking for a reliable engine that can provide plenty of torque while still getting great gas mileage then there’s no better choice than the 5.3 Vortec!

Credit: www.corvetteforum.com

2005 5.3 Head Bolt Torque Specs

When replacing the cylinder head bolts on a 2005 5.3 liter engine, it is important to use the correct torque specifications for proper installation and operation. The recommended torque specification for these bolts is 105 lb-ft, with an additional 90 degree rotation of the bolt after reaching this point. It is also important to ensure that all bolts are tightened in a crisscross pattern until all are snugly fitted into place.

Ls Head Torque Specs Ft Lbs

When installing any component or part onto your vehicle, it is important to use the correct torque specifications to ensure a secure and safe fit. When tightening cylinder head bolts on an LS engine, you should always use a torque of 70 ft-lbs for all fasteners. Following this specification will help prevent damage and keep your engine running smoothly for many miles ahead!

Gen 3 5.3 Head Bolt Torque Specs

When servicing Gen 3 5.3 engines, it is important to use the correct head bolt torque specs. The recommended torque specifications for these bolts are 11 ft-lbs of initial torque and then an additional 90 degrees of rotation. It is also important to tighten each bolt in a specific sequence, beginning with the center bolts and working outward in a star pattern in order to ensure even clamping force on the cylinder heads.

Following these steps will help ensure that your engine runs smoothly and efficiently.

Conclusion

In conclusion, it is important to have a good understanding of the LS head torque specs. Knowing the exact torque specs can help you make sure your engine runs properly and efficiently while avoiding potential problems due to improper tightening. With the right tools and knowledge, you’ll be able to install or replace your LS heads with confidence.