5.7 Hemi Engine Flow Reduction: Boost Performance Today

The 5.7 Hemi engine is known for its power and performance. But what happens when there’s a flow reduction?

Understanding flow reduction in a 5. 7 Hemi engine is crucial for maintaining its efficiency. Flow reduction can cause various issues, from decreased horsepower to increased fuel consumption. Knowing the common causes and solutions can help you keep your engine running smoothly.

In this blog post, we’ll explore what flow reduction means for your 5. 7 Hemi engine, why it happens, and how to address it. By learning these key points, you can ensure your engine remains in top condition. Whether you’re a car enthusiast or a daily driver, this information will be valuable. Let’s dive in and keep your Hemi performing at its best.

Introduction To 5.7 Hemi Engine

The 5.7 Hemi engine is a popular power unit in the automotive world. Known for its robust performance and reliability, it has become a favorite among car enthusiasts. This section provides a comprehensive introduction to the 5.7 Hemi engine, detailing its historical background and unique features.

Historical Background

The 5.7 Hemi engine has a rich history that dates back to the early 2000s. Chrysler introduced this engine as part of their new line of V8 engines. The name “Hemi” comes from the hemispherical combustion chambers, which enhance efficiency and power. Initially, the 5.7 Hemi engine was used in trucks and SUVs. It soon became popular in performance cars due to its impressive power and torque.

Unique Features

The 5.7 Hemi engine stands out for several unique features. One key feature is the hemispherical combustion chamber. This design allows for better airflow and more complete combustion. Another notable feature is the Multi-Displacement System (MDS). This system improves fuel efficiency by deactivating half of the cylinders under light load conditions. The engine also boasts a high compression ratio, contributing to its strong performance.

Additionally, the 5.7 Hemi engine is known for its durability. It uses high-quality materials and advanced engineering techniques. This ensures long-lasting performance and reliability. Overall, the 5.7 Hemi engine offers a blend of power, efficiency, and durability. These qualities make it a preferred choice for many vehicle owners and enthusiasts.

Credit: www.autozone.com

Flow Reduction Techniques

Flow reduction techniques are essential to improve the performance of the 5.7 Hemi engine. By optimizing air intake and upgrading the exhaust system, you can enhance engine efficiency and power. These methods help in reducing resistance and improving airflow, leading to better engine performance.

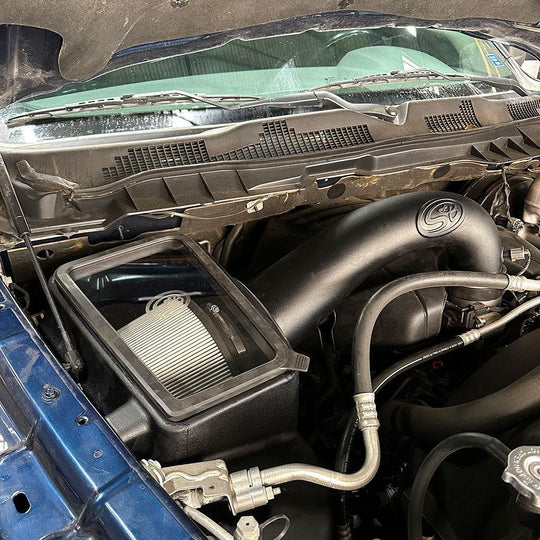

Air Intake Optimization

Air intake optimization is a key technique for reducing flow restrictions. Start with a high-flow air filter. This allows more air into the engine. Consider a cold air intake system. It reduces the temperature of the incoming air. Cooler air is denser and contains more oxygen. This improves combustion efficiency and power output.

Also, inspect the air intake ducts. Ensure they are clean and free from obstructions. Smooth out any rough edges or bends in the ducts. This reduces turbulence and allows a smoother airflow. A well-designed air intake system can significantly enhance engine performance.

Exhaust System Upgrades

Upgrading the exhaust system is another effective flow reduction technique. Begin with high-flow exhaust headers. They reduce backpressure and improve exhaust gas flow. This leads to better engine performance and efficiency.

Next, consider a performance exhaust system. These systems have larger diameter pipes and fewer restrictions. This allows exhaust gases to exit the engine more efficiently. A free-flowing exhaust system reduces engine load and increases power output.

Additionally, install a high-flow catalytic converter. It helps in reducing backpressure further. This ensures that the exhaust gases are expelled quickly and efficiently. A well-designed exhaust system upgrade can greatly improve the 5.7 Hemi engine’s performance.

Boosting Performance

When it comes to enhancing the power and efficiency of your 5.7 Hemi engine, understanding flow reduction is crucial. This process can significantly impact your vehicle’s overall performance. Let’s dive into the key aspects of boosting performance through flow reduction, specifically focusing on power gains and fuel efficiency.

Power Gains

One of the primary reasons enthusiasts focus on flow reduction is the potential for power gains. By optimizing the air and fuel mixture, you can achieve a noticeable increase in horsepower. Think of it as giving your engine a breath of fresh air. With improved airflow, the engine can burn fuel more efficiently, resulting in more power.

Imagine driving down the highway, feeling the surge of energy as you press the accelerator. That’s the magic of effective flow reduction. It’s not just about raw power, but also about how smoothly your engine runs. With the right modifications, your 5.7 Hemi can perform like a dream.

Fuel Efficiency

Now, let’s talk about fuel efficiency. Yes, you heard it right. Boosting performance doesn’t always mean guzzling more fuel. In fact, with proper flow reduction, your engine can become more fuel-efficient. By optimizing the air and fuel mixture, your engine burns fuel more completely, which can lead to better mileage.

Picture this: cruising longer distances without the constant worry of refueling. That’s what improved fuel efficiency offers. It’s a win-win situation – more power and less frequent stops at the gas station. Plus, who doesn’t like saving a few bucks on fuel?

In conclusion, enhancing the performance of your 5.7 Hemi engine through flow reduction is like tuning a musical instrument. It’s about finding that perfect balance of power and efficiency. Whether you’re chasing power gains or better fuel efficiency, understanding and implementing flow reduction can make a world of difference.

Credit: sbfilters.com

Common Challenges

The 5.7 Hemi engine is known for its power and reliability. But it faces some common challenges that can affect its performance. Understanding these challenges helps in maintaining the engine effectively.

Heat Management

Heat is a major concern for the 5.7 Hemi engine. Excessive heat can reduce engine efficiency and cause damage. Proper cooling systems are crucial. Ensure your cooling system is working well to avoid overheating.

Regular checks of the radiator and coolant levels are necessary. Overheating can lead to serious engine issues. Keeping the engine cool ensures better performance and longevity.

Component Wear

Component wear is another common challenge. The engine parts wear out over time. Regular inspections help in identifying worn-out parts early.

Replacing worn-out parts promptly is vital. Neglecting this can lead to bigger issues and costly repairs. Pay attention to signs of wear and tear for a smoother engine operation.

Advanced Modifications

Advanced modifications enhance the performance of your 5.7 Hemi engine. These modifications can significantly improve the engine’s flow, power, and efficiency. Two popular advanced modifications are turbocharging and supercharging.

Turbocharging

Turbocharging your 5.7 Hemi engine involves adding a turbocharger. This device forces more air into the engine’s combustion chamber. More air means more power. Turbochargers use the engine’s exhaust gases to spin a turbine. This turbine compresses the incoming air. Compressed air helps the engine burn more fuel efficiently. This results in increased horsepower and torque. Turbocharging is an effective way to boost engine performance. It enhances both power and fuel efficiency.

Supercharging

Supercharging is another method to improve your 5.7 Hemi engine’s performance. A supercharger also forces more air into the engine. Unlike a turbocharger, it uses a belt connected to the engine. This belt drives the supercharger. Superchargers provide immediate power boosts. They do not rely on exhaust gases. This means there is no lag in power delivery. Supercharging increases the engine’s horsepower and torque. It is ideal for those who seek instant performance gains.

Maintaining Reliability

Maintaining the reliability of the 5.7 Hemi engine is crucial for its longevity. A well-maintained engine performs better and lasts longer. This section outlines the key practices to ensure your engine remains dependable.

Regular Maintenance

Regular maintenance is essential for the 5.7 Hemi engine. Schedule regular oil changes to keep the engine parts lubricated. Clean oil reduces friction and wear. Check and replace the air filter. A clean air filter helps the engine breathe better. Inspect the coolant levels. Proper coolant levels prevent overheating. Keep an eye on the spark plugs. Replace them if they show signs of wear. Follow the manufacturer’s maintenance schedule. It ensures the engine runs smoothly.

Quality Parts

Use quality parts for repairs and replacements. Cheap parts can lead to engine failure. Genuine parts fit better and last longer. They are designed for your specific engine. Use high-quality oil and filters. They keep the engine clean and efficient. Avoid aftermarket parts that are not certified. They can cause more harm than good. Ensure all parts meet the engine’s specifications. Quality parts maintain the engine’s performance and reliability.

Cost Considerations

When considering any modifications or upgrades to your vehicle, understanding the associated costs is crucial. The 5.7 Hemi engine is popular among car enthusiasts for its performance. However, implementing flow reduction for better efficiency or power can come with a price tag. Let’s break down the cost considerations you should keep in mind.

Initial Investment

The initial investment in a 5.7 Hemi engine flow reduction can vary. Here’s a quick breakdown:

- Basic Kits: These usually range from $200 to $500. They include essential components and instructions.

- Advanced Kits: If you want more performance, expect to spend between $500 and $1,000. These kits have high-quality parts and more detailed instructions.

- Professional Installation: If you’re not a DIY enthusiast, hiring a professional can add another $300 to $800 to your costs.

When I first considered flow reduction for my Hemi, I was overwhelmed by the choices. But after some research and a bit of elbow grease, I opted for a mid-range kit and did the installation myself. It wasn’t too tough, and I saved a bit on labor costs.

Long-term Costs

Looking beyond the initial investment, it’s important to consider long-term costs:

- Maintenance: Regular check-ups and potential part replacements. Budget around $100 to $200 annually for maintenance.

- Fuel Efficiency: You might see a slight improvement in fuel efficiency. This can save you money over time, especially if you drive a lot.

- Potential Repairs: Any modification can lead to unforeseen issues. Set aside an emergency fund of $200 to $500 for repairs.

One thing I’ve learned from my experience is to always keep a little extra cash for surprises. You never know when a part might fail or need a tweak.

| Cost Aspect | Estimated Amount |

|---|---|

| Basic Kit | $200 – $500 |

| Advanced Kit | $500 – $1,000 |

| Professional Installation | $300 – $800 |

| Annual Maintenance | $100 – $200 |

| Emergency Repairs | $200 – $500 |

In conclusion, while the initial investment for a 5.7 Hemi engine flow reduction might seem steep, the long-term benefits and potential savings in fuel efficiency can make it worthwhile. Just remember to budget for maintenance and possible repairs. After all, a well-maintained engine is key to enjoying your ride for years to come.

Case Studies

The 5.7 Hemi engine has been a popular choice for performance enthusiasts. To understand its flow reduction better, we examined several case studies. These examples show different approaches and outcomes. Each offers valuable insights for anyone interested in optimizing their Hemi engine.

Successful Builds

One notable case involved a 2010 Dodge Charger. The owner aimed to enhance engine flow for better performance. They installed high-flow headers and a cold air intake. The results were impressive. The car gained significant horsepower and torque. The modifications also improved fuel efficiency. This case shows how targeted upgrades can yield substantial benefits.

Another example featured a 2015 Ram 1500. This truck underwent a comprehensive engine rebuild. The focus was on reducing flow restrictions. The team used ported cylinder heads and a performance camshaft. Post-modification, the truck showed remarkable power gains. The engine ran cooler and more efficiently. This build demonstrated the potential of strategic modifications.

Lessons Learned

From these case studies, several lessons emerge. First, quality components matter. Using high-quality parts ensures better performance and longevity. Second, a balanced approach is key. Focusing on one aspect may not yield the best results. Instead, consider the engine as a whole.

Testing and tuning are crucial. Each engine reacts differently to modifications. Regular testing helps fine-tune the setup for optimal performance. Documentation is vital. Keeping detailed records of changes and outcomes aids future projects. It also helps in troubleshooting any issues that arise.

Credit: www.ebay.com

Frequently Asked Questions

What Is The Most Common Problem With The 5.7 Hemi?

The most common problem with the 5. 7 HEMI is the MDS (Multi-Displacement System) lifter failure. This issue can cause engine ticking. Regular maintenance can help mitigate this problem.

How To Stop 5.7 Hemi Tick?

Use high-quality oil, replace lifters, and ensure proper lubrication. Regular maintenance and oil changes prevent 5. 7 HEMI tick.

What Year Did 5.7 Hemi Have Mds?

The 5. 7 HEMI engine first featured Multi-Displacement System (MDS) technology in 2006. This system improves fuel efficiency.

How Common Is Lifter Failure On 5.7 Hemi?

Lifter failure on the 5. 7 HEMI is relatively common. Many owners report issues around 100,000 miles. Regular maintenance can help prevent it.

Conclusion

The 5. 7 Hemi engine flow reduction impacts performance. Understanding these changes helps with maintenance. Regular checks ensure optimal function. Avoiding flow issues keeps your engine running smoothly. Paying attention to the details prevents bigger problems. Efficient engines save money on repairs.

Keeping an eye on flow reduction improves engine life. Simple steps can make a big difference. Stay informed and proactive. Your engine will thank you.