6.7 Cummins Thermostat Location & Replacement Full Guides (All Years)

The thermostat in your 6.7L Cummins engine is a small, unassuming valve that plays an outsized role in the health and performance of your truck. It is the gatekeeper of the cooling system, a critical regulator that dictates engine temperature. Its proper function directly impacts everything from fuel efficiency and cabin heat to the complex operations of your emissions system and the long-term durability of the engine itself.

For those searching for a quick answer, here it is: The thermostat on a 6.7L Cummins engine is located at the front of the engine, inside a cast housing where the upper radiator hose connects to the cylinder head.

However, this simple description belies the reality of the job. While finding the thermostat housing is straightforward, actually accessing it is the real challenge. On these modern diesels, critical components like the EGR (Exhaust Gas Recirculation) crossover tube are routed directly over the thermostat housing, requiring their removal before the thermostat can be serviced.

This guide provides a comprehensive, data-driven walkthrough for every 6.7L Cummins owner, covering how to pinpoint the location on your specific model year, definitively diagnose a failure, perform a step-by-step replacement, and select the correct OEM parts to protect your investment.

The 6.7L Cummins Thermostat

A data-driven guide to location, symptoms, and replacement.

The Engine’s Gatekeeper

The thermostat is a small but mighty valve that regulates coolant flow to maintain the engine’s ideal operating temperature.

Optimal Operating Temp

190°F

(~88°C)

Pinpointing the Location

Finding the thermostat is straightforward. It’s housed where the main coolant hose from the radiator connects to the engine block. Follow this path:

1. Radiator

Identify the top

2. Upper Hose

Follow the large hose

3. Thermostat Housing

Where the hose meets the engine

Diagnosing Failure: Symptoms & Modes

A failing thermostat typically gets stuck in one of two positions, each with distinct symptoms. A “stuck open” failure is far more common and less catastrophic than a “stuck closed” failure.

- Overheating Engine: Temp gauge climbs into the red zone (Stuck Closed).

- Engine Not Reaching Temp: Takes forever to warm up, gauge stays low (Stuck Open).

- Poor Fuel Economy: Engine runs rich and inefficiently when too cool.

- Reduced Heater Performance: Not enough heat in the cabin during cold weather.

The Impact of a Failing Thermostat

The consequences of a faulty thermostat go beyond inconvenience, directly affecting your truck’s performance and health. This chart compares key metrics between a healthy system and one with a common ‘stuck open’ failure.

Replacement Snapshot

💵

Part Cost

$40 – $90

⏱️

DIY Time

1-2 Hours

🔧🔧🔧🔧🔧

Difficulty

Low to Moderate

Choosing the Right Replacement

Not all thermostats are the same. The primary difference is the temperature rating, which affects when the valve opens. The stock 190°F unit is ideal for most applications, ensuring efficient warm-up and performance.

| Feature | 190°F (Stock) | 200°F (High Temp) |

|---|---|---|

| Best For | Daily driving, light towing, OEM performance | Heavy towing in very cold climates |

| Fuel Economy | Optimized for efficiency | May see a slight decrease |

| Engine Warm-up | Faster, as designed | Slightly slower |

Pinpointing the 6.7 Cummins Thermostat Location (By Model Year)

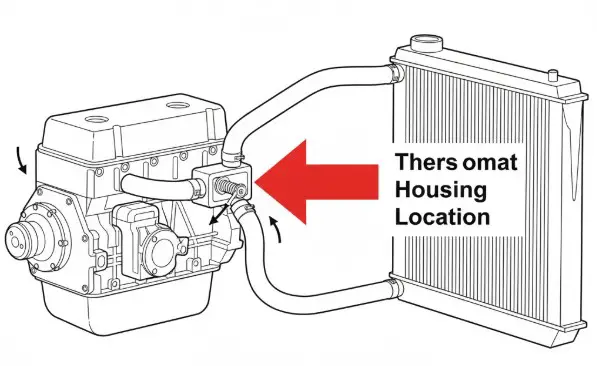

The fundamental location of the 6.7L Cummins thermostat is consistent across all generations of the engine. To find it, simply follow the large-diameter upper coolant hose from the top of the radiator back to where it connects to the engine block. The thermostat is housed within the metal elbow that this hose clamps onto.

A simple diagram illustrating the cooling system layout would be beneficial here. It would show the radiator on one side and the engine block on the other, connected by the upper radiator hose. An arrow would point specifically to the thermostat housing at the engine-side connection of the hose, clearly labeled “Thermostat Housing Location.”

While the location is consistent, the components that obstruct access have minor variations between model year ranges. The placement of the thermostat underneath the emissions system reflects a common design reality in modern diesel engines: the complex packaging and routing required for emissions components often take precedence over the serviceability of maintenance items. This decision increases the labor involved but is a necessary trade-off to meet stringent environmental regulations.

Access Challenges Across Generations

- 2007.5 – 2012 Models: On the fourth-generation trucks, the primary obstacle is the EGR crossover tube, which runs directly over the top of the thermostat housing. To gain access, you must first remove the plastic engine shroud (often called a “beauty cover”), and then proceed to disconnect and remove the EGR tube. In some cases, a small heat shield may also need to be unbolted to provide clear access to the housing bolts.

- 2013 – 2018 Models: The engine bay layout for these model years is very similar to the earlier fourth-gen trucks. The replacement procedure remains largely the same, with the EGR crossover tube being the main component that needs to be removed for access. While the thermostat housing itself may carry a different part number for this generation, the fundamental steps to reach it are consistent with earlier models.

- 2019+ Models: For the latest generation of Ram trucks, the thermostat is still found where the upper radiator hose meets the engine. The housing is a different part number specific to these newer models, but the general principle of the replacement job remains the same. You will still need to remove overlying components to access the housing for service.

Is Your Thermostat Failing? Key Symptoms to Watch For

A thermostat can fail in two primary ways: it can get stuck open, or it can get stuck closed. Each failure mode presents a distinct set of symptoms that can help you diagnose the problem accurately.

Failure Mode 1: Stuck Open (Engine Runs Too Cool)

This is the more common failure mode for modern thermostats, which are often designed with a failsafe to prevent catastrophic overheating.

- Slow Engine Warm-Up: The most obvious sign is an engine that takes an exceptionally long time to reach its normal operating temperature. The temperature gauge on your dashboard may never climb to its usual position (around 190-200°F) during your commute.

- Poor Cabin Heat: If your truck’s heater is blowing lukewarm or cold air, especially on a cold day, it’s a strong indicator that the thermostat is stuck open. The coolant is not getting hot enough to effectively transfer heat to the heater core inside your dashboard.

- Decreased Fuel Economy: An engine that runs too cool is inefficient. The Engine Control Unit (ECU) will maintain a richer fuel mixture in an attempt to bring the engine up to temperature, leading to a noticeable drop in your miles per gallon.

- Check Engine Light: A thermostat stuck open will often trigger a Check Engine Light with diagnostic trouble codes such as P0128 (Coolant Thermostat Temperature Below Regulating Temperature) or P0125 (Insufficient Coolant Temperature for Closed Loop Fuel Control).

A stuck-open thermostat on a 6.7L Cummins is more than just an inconvenience; it poses a direct threat to the expensive aftertreatment system. The Diesel Particulate Filter (DPF) requires a high-temperature “regeneration” cycle to burn off trapped soot. The ECU will not initiate this cycle unless the engine coolant reaches a minimum operating temperature. If the thermostat is stuck open, the engine never gets hot enough, regeneration is inhibited, and the DPF will continue to clog with soot.

This can lead to a derated engine, costly forced regenerations at a dealership, or even permanent DPF damage—all stemming from a simple, inexpensive cooling system component.

Failure Mode 2: Stuck Closed (Engine Overheats)

A thermostat stuck in the closed position is a more urgent and potentially damaging failure.

- High Temperature Gauge Reading: The temperature gauge will climb rapidly past the normal range and into the red. Any reading above 220-230°F under normal driving conditions is a cause for immediate concern.

- Coolant Boil-Over: As the coolant trapped in the engine block heats up beyond its boiling point, pressure builds, potentially forcing steam and coolant out of the reservoir cap.

- Gurgling or Boiling Sounds: You may hear unusual sounds from the engine bay, indicating that the coolant is boiling.

Other Symptoms

- Erratic Temperature Fluctuations: If the temperature gauge swings up and down unpredictably, it suggests the thermostat valve is sticking intermittently and not opening and closing smoothly.

- Coolant Leaks: Puddles of orange or pinkish coolant under the front of your truck can indicate a failed seal around the thermostat housing. This leak may be more prominent when the engine is cold.

The Complete 6.7 Cummins Thermostat Replacement Guide

This section provides a detailed, step-by-step process for replacing the thermostat. While the job is manageable for a skilled DIY mechanic, it requires patience and the right tools due to the access challenges.

A. Essential Tools and Parts List

Gathering all necessary components before you begin is crucial for a smooth and successful repair. This prevents delays and ensures you have everything on hand once the truck is taken apart.

| Category | Item | Details / Notes |

| Parts | New OEM Thermostat | Use the correct temperature rating for your model year (see table below). |

| New Thermostat Seal | Often included with the thermostat; Cummins P/N 3954829 fits most years.15 | |

| HOAT Coolant | Must meet Cummins CES14603 spec. Mopar 10-year/150k or ZEREX G-05 are correct.3 | |

| Distilled Water | For mixing with concentrated coolant to achieve a 50/50 ratio. | |

| Tools | Ratchet & Socket Set | A set with various extensions is essential for reaching bolts.6 |

| Specific Sockets/Wrenches | 8mm (shroud), 12mm (housing), 7/16-inch (EGR clamps).6 | |

| Drain Pan | Minimum 2-gallon capacity. | |

| Pliers | For hose clamps and connectors. | |

| Flathead Screwdriver | For gently prying out the old thermostat.5 | |

| Torque Wrench | To ensure housing bolts are tightened to the correct specification. | |

| Gasket Scraper / Razor | For cleaning old seal material from mating surfaces. | |

| Shop Rags | For cleaning surfaces and managing spills. |

B. Step-by-Step Replacement Procedure

Step 1: Safety First & Preparation

Ensure the engine is completely cool to the touch. Working on a hot cooling system is extremely dangerous. Disconnect the negative terminals from both batteries. Open the coolant reservoir cap to release any residual pressure in the system.

Step 2: Drain the Coolant

Place a large drain pan under the lower driver’s side of the radiator. Locate the plastic petcock (drain valve) and open it slowly. Drain at least one gallon of coolant. This will lower the coolant level below the thermostat housing and prevent a large spill when you remove the upper hose and housing.

Step 3: Remove Obstructions

This is the most involved part of the job. Using an 8mm socket, remove the bolts securing the plastic engine cover and set it aside. Next, focus on the EGR crossover tube. Use a 7/16-inch socket to loosen the clamps on both ends of the tube. Carefully disconnect any attached electrical connectors and sensor lines before removing the tube completely.

Step 4: Access the Thermostat Housing

With the EGR tube removed, you will have a clear view of the thermostat housing. Disconnect the electrical connector for the coolant temperature sensor and the small tube for the exhaust pressure sensor that are attached to the housing.3

Step 5: Remove the Old Thermostat

Using a 12mm socket or wrench, remove the three bolts that hold the thermostat housing to the cylinder head. Carefully lift the housing away. The thermostat sits inside the port on the engine block. Using a flathead screwdriver, gently pry the old thermostat up and out of its seat. Pay attention to its orientation—the spring side should be facing down into the engine.

Step 6: Clean and Install the New Thermostat

Thoroughly clean the mating surfaces on both the engine block and the thermostat housing. All traces of the old seal must be removed to ensure a proper seal. Place the new rubber seal onto the new thermostat. Insert the new thermostat assembly into the engine block, making sure the spring side is down and it is fully seated.

Step 7: Reassembly

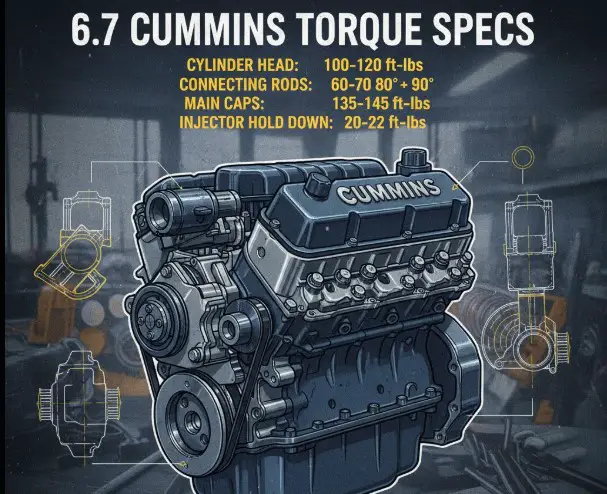

Reinstall the thermostat housing, ensuring it sits flat against the block. Hand-tighten the three 12mm bolts, then use a torque wrench to tighten them to the manufacturer’s specification in a crossing pattern. Reconnect the exhaust pressure sensor tube and the coolant temperature sensor electrical connector. Carefully reinstall the EGR crossover tube, tightening the clamps securely and reattaching all connectors. Finally, reinstall the plastic engine cover.

Step 8: Refill and Bleed the System

Close the radiator petcock. Refill the cooling system through the reservoir with a 50/50 mixture of the correct HOAT coolant and distilled water. Leave the reservoir cap off, turn the truck’s heater on to the highest temperature and fan setting, and start the engine. Let it idle and monitor the coolant level in the reservoir, adding more as it drops. As the engine warms up, the new thermostat will open, circulating the coolant and purging air from the system.

Once the engine reaches operating temperature and the coolant level stabilizes, reinstall the reservoir cap. Check carefully for any leaks around the thermostat housing. Monitor the coolant level for the next few drive cycles and top off as necessary.

Choosing the Right Thermostat: Part Numbers and Temperature Ratings

Selecting the correct thermostat is not just about fitment; it’s about ensuring your engine operates within the temperature range it was designed for. Using the wrong part can negatively impact performance and emissions system function.

Understanding Temperature Ratings

The 6.7L Cummins has used two primary stock temperature ratings over its production run: 190°F and 200°F.

- 190°F Thermostat: This is the standard temperature for most model years, including 2007.5-2009 and 2013-present. It provides a good balance of efficient warm-up and effective cooling under load.

- 200°F Thermostat: Ram used a hotter 200°F thermostat exclusively in the 2010-2012 model years. This was likely an emissions-driven strategy to increase engine operating temperatures for a more complete combustion process and to aid in DPF regeneration cycles. While a 190°F thermostat can be used in these trucks (and is often preferred by those who tow in hot climates), the OEM specification is 200°F.

OEM 6.7L Cummins Thermostat Part Numbers by Year

Using an OEM (Original Equipment Manufacturer) part from Cummins or Mopar is highly recommended. A critical design feature of these thermostats is that they are engineered to fail in the open position, a failsafe that prevents catastrophic engine overheating. Many cheaper aftermarket alternatives may fail in the closed position, which can lead to severe engine damage. The following table consolidates part numbers from various sources to provide a definitive reference guide.

| Model Years | Stock Temp | OEM Cummins P/N | OEM Mopar P/N | Notes |

| 2007.5 – 2009 | 190°F | 5627589 | 68534176AA | Supersedes multiple older part numbers.18 |

| 2010 – 2012 | 200°F | N/A | 68067109AB | This is the specific higher-temp thermostat for these years.23 |

| 2013 – 2024+ | 190°F | 5627589 | 68534176AA | The engine platform reverted to the 190°F standard.18 |

Coolant Specifications: Using the Correct Fluid

Using the wrong type of engine coolant can cause significant and expensive damage to your cooling system. The 6.7L Cummins has specific requirements that must be followed.

The engine requires a Hybrid Organic Acid Technology (HOAT) coolant. Specifically, the coolant must meet Cummins Engineering Standard (CES) 14603. Using an incompatible coolant like conventional green IAT (Inorganic Additive Technology) or orange OAT (Organic Acid Technology, like Dex-Cool) can lead to chemical reactions that cause corrosion, silicate precipitation (which clogs radiators and heater cores), and damage to seals and water pump bearings.

| Specification | Value |

| Coolant Type | HOAT, meeting Cummins CES14603 |

| Recommended Products | Mopar 10-year/150,000 Mile, ZEREX G-05 |

| System Capacity | Approx. 5.7 – 6.0 Gallons (22.8 – 24 Quarts) |

| Mixture | 50/50 with Distilled Water |

When refilling the system, always use a 50/50 mixture of coolant concentrate and distilled water. Never use tap water, as its mineral content can cause scale buildup within the cooling system. For more information on coolant technology, a reliable source like the Valvoline website can provide additional details.

Debunking the Myth: Does the 6.7 Cummins Have a Dual Thermostat?

A common question among diesel owners is whether their engine uses a dual-thermostat system. To be clear, the 6.7L Cummins engine found in Ram pickup trucks uses a single thermostat design.1

The confusion often arises because some larger, heavy-duty diesel engines used in semi-trucks, agricultural machinery, and industrial applications do feature a dual-thermostat cooling system. In those systems, a primary thermostat opens at a lower temperature for light-load operation and faster warm-up, while a secondary, higher-temperature thermostat opens only under heavy load to allow full coolant flow to an oversized radiator. This complex design is not implemented on the Ram 6.7L platform, which effectively manages its temperature with a single, robust thermostat

Conclusion: Protecting Your Investment

The thermostat is a small part with a massive responsibility. Its location, buried under the EGR system, makes replacement more involved than on older engines, but it is a critical maintenance task that a knowledgeable owner can perform. By understanding the symptoms of a failing thermostat—whether it’s running too cool and threatening your DPF, or running too hot and risking engine damage—you can intervene before a minor issue becomes a major repair bill.

Proper maintenance is about more than just fixing what’s broken; it’s about preserving the performance, reliability, and longevity of your truck. Always use the correct OEM-spec thermostat for your model year and the required HOAT coolant. A properly functioning cooling system is the foundation of a healthy Cummins engine, protecting your entire powertrain and ensuring your truck is ready to work for years to come.

Frequently Asked Questions (FAQ)

What temperature should my 6.7 Cummins run at?

A healthy 6.7L Cummins should operate between 190°F and 210°F under normal conditions. The thermostat will begin to open at its rated temperature (190°F or 200°F), but it’s normal for coolant temperatures to climb slightly higher under load, such as when towing up a grade.20

Can I drive with a bad 6.7 Cummins thermostat?

It is strongly advised not to. A thermostat stuck closed will cause rapid overheating, risking severe engine damage like a warped cylinder head or blown head gasket.10 A thermostat stuck open is also problematic; it prevents the engine from reaching operating temperature, which harms fuel economy and, critically, prevents the DPF from regenerating, leading to a clogged filter and expensive repairs.

How much does it cost to replace a 6.7 Cummins thermostat?

For a DIY repair, the cost is limited to parts, typically $60-$100 for an OEM thermostat and seal, plus another $40-$60 for fresh coolant.23 If you take it to a repair shop, expect to pay for 2-4 hours of labor due to the need to remove the EGR tube. The total cost can range from $400 to $700, depending on local labor rates.

Is a 190° thermostat better than a 200° for my 2011 Cummins?

For a stock 2010-2012 truck, the factory-specified 200°F thermostat is recommended as it aligns with the original emissions tuning. However, many owners successfully use a 190°F thermostat to run the engine slightly cooler, which can be beneficial when towing in hot climates. For trucks with emissions systems removed (“deleted”), a 190°F thermostat is commonly preferred.

What coolant does a 6.7 Cummins take?

The 6.7L Cummins requires a Hybrid Organic Acid Technology (HOAT) coolant that meets the Cummins CES14603 specification, mixed 50/50 with distilled water. Common compatible coolants include Mopar 10-year/150,000 mile formula and ZEREX G-05. Do not use conventional green coolant or OAT coolants like Dex-Cool.