7.3 Crankshaft Position Sensor: Ultimate Guide to Troubleshooting

The 7.3 Crankshaft Position Sensor is crucial for your vehicle’s engine. It helps monitor the crankshaft’s position and speed.

This sensor ensures your engine runs smoothly and efficiently. In modern vehicles, the crankshaft position sensor plays a vital role. It provides the engine control unit (ECU) with essential data. This data helps regulate fuel injection and ignition timing. If the sensor fails, your engine might stall or not start at all.

Understanding the importance of this sensor can save you from unexpected issues. This blog post will explore the function, common problems, and maintenance tips for the 7. 3 crankshaft position sensor. Stay tuned to learn how this small component impacts your vehicle’s performance.

Introduction To Crankshaft Position Sensor

The crankshaft position sensor is a vital component in modern engines. It helps monitor the position and rotational speed of the crankshaft. This data is crucial for the engine control unit (ECU) to optimize engine performance. Understanding its role can help you appreciate its importance.

Purpose And Function

The crankshaft position sensor measures the position of the crankshaft. It sends this information to the ECU. The ECU uses this data to manage the ignition timing and fuel injection. Accurate readings are essential for smooth engine operation. Without it, the engine may misfire or fail to start.

Importance In Engine Performance

The crankshaft position sensor plays a key role in engine performance. It ensures the engine runs efficiently and smoothly. Proper ignition timing and fuel injection improve fuel economy. They also reduce emissions. A faulty sensor can lead to poor engine performance. It can cause stalling, increased fuel consumption, and rough idling.

Regular maintenance and timely replacement of the sensor can prevent these issues. It helps maintain optimal engine performance. This small component has a big impact on how your engine runs.

Credit: www.dieselhub.com

How The Crankshaft Position Sensor Works

The crankshaft position sensor is a crucial component in modern engines. It monitors the position and rotational speed of the crankshaft. This data is vital for engine timing and fuel injection. Understanding how this sensor works can help in diagnosing engine issues.

Basic Principles

The crankshaft position sensor detects the position of the crankshaft. It uses magnetic or optical methods to sense rotation. This information is sent to the engine control unit (ECU). The ECU uses this data to control ignition timing and fuel injection.

Sensor Types And Variations

There are different types of crankshaft position sensors. Magnetic sensors are common. They generate a signal based on the crankshaft’s rotation. Optical sensors use light to detect position. Both types provide accurate data to the ECU.

Variations exist based on engine design. Some sensors are placed near the flywheel. Others are located at the front of the engine. The sensor’s location affects its design and functionality.

Common Symptoms Of A Faulty Sensor

A faulty 7.3 Crankshaft Position Sensor can cause various issues in your vehicle. Recognizing these symptoms early can prevent serious engine damage. Here are common signs of a bad sensor:

Engine Misfires

Engine misfires occur when the sensor fails to send accurate data. The engine may hesitate or jerk during acceleration. Misfires can lead to rough idling and poor performance.

Starting Problems

A faulty sensor can cause starting problems. The engine may crank but fail to start. This happens because the sensor cannot detect the crankshaft’s position. Without this information, the engine control module can’t start the engine.

Poor Fuel Efficiency

Poor fuel efficiency is another symptom. The sensor’s incorrect data affects the fuel injection timing. This leads to increased fuel consumption and reduced mileage. You may notice frequent visits to the gas station.

Diagnosing Crankshaft Position Sensor Issues

Understanding and diagnosing issues with the 7.3 Crankshaft Position Sensor (CPS) can be a bit of a puzzle, but it’s a crucial part of keeping your engine running smoothly. This sensor monitors the position and rotational speed of the crankshaft, sending important data to the engine control unit (ECU). When it malfunctions, your vehicle can experience a range of problems, from poor starting to stalling. Let’s dive into some effective ways to diagnose these issues.

Using Diagnostic Tools

One of the most efficient ways to identify problems with the Crankshaft Position Sensor is by using diagnostic tools. You don’t need to be a professional mechanic to use these tools. A basic OBD-II scanner, which you can find at most auto parts stores, can be a game-changer.

- Step 1: Connect the OBD-II scanner to your vehicle’s diagnostic port, usually located under the dashboard.

- Step 2: Turn on the ignition, but do not start the engine.

- Step 3: Follow the scanner’s instructions to read any error codes.

Look for codes related to the Crankshaft Position Sensor. Common ones include P0335, which indicates a malfunction, or P0336, which suggests a performance issue. If you see these codes, it’s a good indication that your CPS is having trouble.

Visual Inspection Tips

Sometimes, the issues with your CPS can be detected through a simple visual inspection. This might sound basic, but it’s often very effective.

- Check the Wiring: Make sure all wires connected to the sensor are intact and free from damage. Look for signs of wear or fraying.

- Inspect the Sensor: The sensor itself should be clean and free from oil or other contaminants. Dirt or grime can interfere with its function.

- Look for Loose Connections: Ensure that the sensor is securely connected. A loose connection can cause intermittent issues that are hard to diagnose.

Remember, a clean, well-connected sensor is a happy sensor. If you spot any issues, addressing them can often solve the problem without further hassle.

Diagnosing problems with the 7.3 Crankshaft Position Sensor doesn’t have to be overwhelming. With the right tools and a keen eye, you can identify and fix issues before they escalate. Got any tips or experiences with CPS issues? Share them in the comments below!

Troubleshooting Techniques

Facing issues with your 7.3 Crankshaft Position Sensor can be frustrating. It is essential to know the right troubleshooting techniques. This helps in identifying and fixing the problem quickly. Below are some effective methods to diagnose issues with your sensor.

Checking Wiring And Connections

Start with a visual inspection of the wiring and connections. Look for any signs of wear or damage. Ensure all connectors are secure and free of corrosion. Loose or corroded connections can cause sensor malfunction. Gently tug on the wires to check for loose connections. This simple step can often reveal the source of the problem.

Testing Sensor Output

Testing the sensor output is crucial in diagnosing issues. Use a multimeter to measure the voltage. Connect the multimeter leads to the sensor terminals. Crank the engine and observe the voltage readings. The sensor should produce a consistent signal. If the readings are erratic or non-existent, the sensor may be faulty. This test helps confirm whether the sensor needs replacement.

Credit: www.powerstroke.org

Replacing The Crankshaft Position Sensor

Replacing the crankshaft position sensor can improve your vehicle’s performance. It ensures the engine runs smoothly. This guide will help you replace the sensor step-by-step.

Required Tools And Materials

Before starting, gather the necessary tools and materials. You will need a socket set, a ratchet, and a new crankshaft position sensor. A jack and jack stands are also essential. Wear safety gloves and glasses for protection. Ensure you have a clean workspace.

Step-by-step Replacement Guide

First, park your vehicle on a flat surface. Engage the parking brake. Use a jack to lift the front of the vehicle. Secure it with jack stands. Disconnect the negative battery cable to ensure safety.

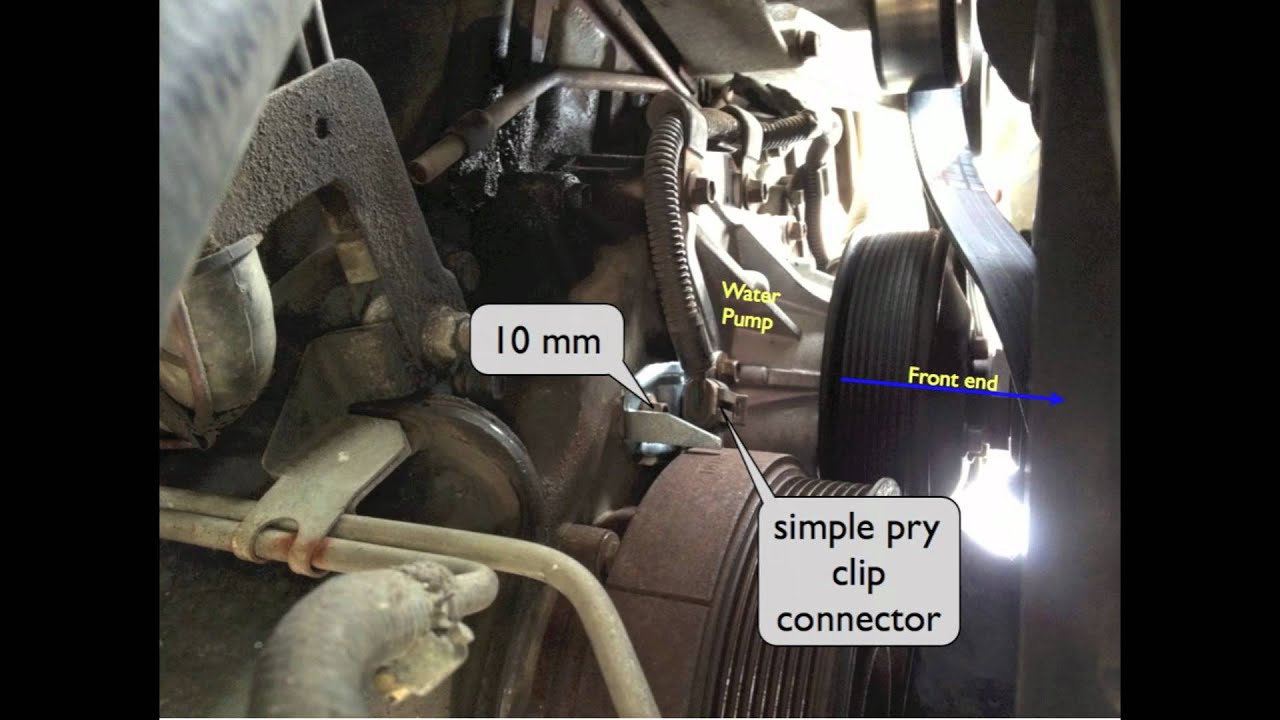

Locate the crankshaft position sensor. It’s usually near the bottom of the engine. Use your socket set and ratchet to remove the bolts holding the sensor. Gently pull the sensor out. Be careful not to damage any surrounding parts.

Install the new sensor by aligning it with the mounting hole. Insert and tighten the bolts. Reconnect the sensor’s electrical connector. Lower the vehicle using the jack. Remove the jack stands. Reconnect the negative battery cable.

Start the engine to ensure the new sensor is working correctly. If the engine runs smoothly, the replacement was successful. If issues persist, consult a professional mechanic.

Preventive Maintenance Tips

The 7.3 Crankshaft Position Sensor is crucial for engine performance. Regular preventive maintenance ensures the sensor functions properly. This helps maintain your vehicle’s efficiency and avoids costly repairs.

Regular Inspection Schedule

Create a schedule to inspect the crankshaft position sensor. Check it every 10,000 miles or as your vehicle’s manual suggests. Early detection of issues can prevent bigger problems. Look for signs of wear or damage. Replace the sensor if needed.

Keeping Sensor Clean

Dirt and debris can affect sensor performance. Regularly clean the sensor and its surroundings. Use a soft cloth or brush to remove any buildup. Avoid using harsh chemicals. Clean the electrical connectors as well. Ensure they are free from corrosion.

Credit: www.amazon.com

Frequently Asked Questions

What Are The Symptoms Of A Failed Crankshaft Position Sensor?

Symptoms of a failed crankshaft position sensor include engine misfires, stalling, difficulty starting, poor acceleration, and reduced fuel efficiency. The check engine light may also illuminate.

How Do I Know If My Cps Is Bad?

A bad CPS (Crankshaft Position Sensor) can cause engine stalling, misfires, poor acceleration, and difficulty starting. Check for these symptoms.

What Is The Common Sensor Problem On The 7.3 Powerstroke?

The common sensor problem on the 7. 3 PowerStroke is the Camshaft Position Sensor (CPS) failure. This can cause stalling or hard starts. Regular checks and timely replacement can prevent issues.

Where Is The Icp Sensor 7.3 Powerstroke?

The ICP sensor on a 7. 3 PowerStroke is located on the driver’s side valve cover. It is near the front of the engine.

Conclusion

A well-functioning crankshaft position sensor ensures your engine runs smoothly. It’s essential for optimal vehicle performance. Regular checks can prevent issues and costly repairs. If your engine shows signs of trouble, inspect the sensor. Replacing a faulty sensor can save time and money.

Maintaining your vehicle’s health is crucial. Keep your crankshaft position sensor in top shape. Your car will thank you. Reliable performance starts with proper maintenance. Stay attentive to your vehicle’s needs.