Cummins Particulate Matter Sensor Location

The Cummins particulate matter sensor is located in the exhaust stream of the engine. It is typically installed downstream from the turbocharger, after all other components such as catalysts and mufflers. The position of the sensor can vary depending on the model and year of engine, but it should always be placed near or at the end of the exhaust system where there are no other obstructions that could interfere with its operation.

This allows for maximum accuracy when measuring particulate matter concentrations in real-time. Additionally, it should be positioned as far away from any heat sources as possible to ensure accurate readings over time without being affected by changes in temperature or humidity levels present within an engine’s environment.

The Cummins particulate matter sensor is located in the exhaust manifold of your engine. This device measures and monitors the amount of soot particles emitted by diesel engines, helping to ensure that they are running efficiently and meeting emission standards. The location of this sensor is important for proper engine performance as it must be placed strategically in order to accurately measure the particulate matter output from your engine.

By strategically placing this sensor, you can help maximize fuel efficiency while ensuring compliance with emissions regulations.

How to replace Pm sensor ( particular matter sensor)

How Do You Clean a Particulate Matter Sensor?

Particulate matter (PM) sensors are essential for monitoring air quality in industrial and residential settings. Cleaning a PM sensor is important to ensure its accuracy and longevity. The process of cleaning a PM sensor is relatively simple but should be done with care as improper cleaning can damage the device.

First, it’s important to disconnect the power source before beginning any work on the device. Next, use compressed air or cotton swabs to gently remove any dirt or dust that may have accumulated on the surface of the sensor itself or inside its housing. Once all visible debris has been removed, use an appropriate cleaner such as alcohol wipes or anti-static solution to clean away any remaining residue and then dry thoroughly with a clean cloth.

Finally, reconnect the power source and test your PM sensor by running it through several cycles at various levels of concentration in order to check for accurate readings after each cycle. Following these steps will help keep your particulate matter sensor functioning properly for years to come!

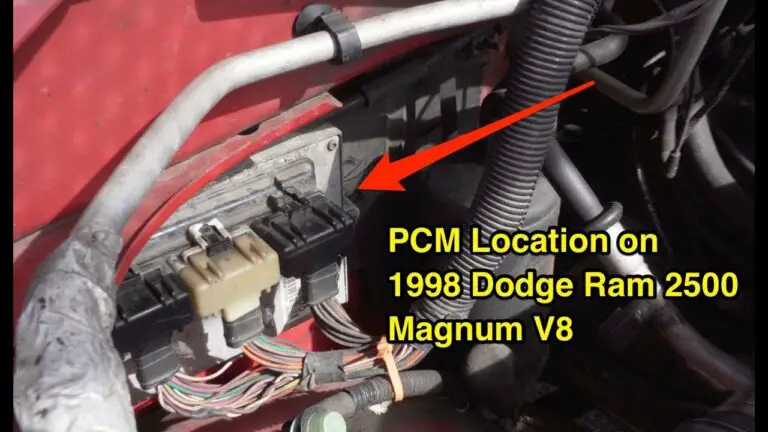

How Do You Replace a Pm Sensor?

Replacing a PM (Particulate Matter) sensor is not an overly complicated process, but it does require some specialized tools and a bit of know-how. The first step is to locate the old sensor and remove it from its mounting bracket or housing. You’ll need to disconnect any wiring harnesses that are attached to the sensor before you can safely remove it.

Once the old unit has been removed, inspect all connections for corrosion or damage before installing your new one. Install your new PM sensor according to manufacturer’s instructions, making sure that all wiring connections are secure and tight so they don’t come loose over time. Finally, start up your vehicle and check for proper operation of the new sensors by monitoring engine performance as well as looking at data readings on scan tools or other diagnostic equipment used in your shop.

If everything looks good then you’ve successfully replaced your PM Sensor!

Where is the Particulate Matter Sensor Located?

Particulate matter sensors are typically located near areas of high pollution or where particulates may be emitted. This includes industrial areas, power plants, and other places where emissions from vehicles and manufacturing processes can take place. These sensors measure the concentration of particulate matter in the air, which is important for monitoring air quality and ensuring that public health standards are met.

The exact location of a particulate matter sensor will depend on its purpose and the type of measurement being taken; generally speaking, they should be placed as far away from sources of pollution as possible to ensure accurate readings. In addition to their placement outdoors near sources of potential pollutants, some particulate matter sensors can also be installed indoors in order to detect any indoor air quality issues that could exist.

What Sensor Detects Particulate Matter?

Particulate matter is a type of air pollution made up of tiny particles suspended in the air. These particles can come from many sources, including factories, vehicles and natural processes such as wind erosion. To measure the presence and concentration of particulate matter in an area, sensors are used to detect it.

Commonly used sensors include optical particle counters (OPCs), beta attenuation monitors (BAMs) and tapered element oscillating microbalances (TEOMs). OPCs use light scattering technology to count the number of particles present in a given volume, while BAMs use laser-based detection systems for monitoring smaller sized particulates. TEOMS measure total mass concentrations by vibrating a thin film that allows for collection on the device’s surface.

Each one has its advantages and disadvantages but all three types have been found to be effective instruments for measuring particulate matter levels in an environment over time or during real-time conditions.

Credit: www.youtube.com

Cummins Aftertreatment Particulate Matter Sensor

The Cummins Aftertreatment Particulate Matter Sensor (PMS) is a device that monitors the exhaust system of diesel-powered vehicles, such as buses and trucks. It measures the amount of particulate matter in the exhaust gases and helps detect potential problems with emission control systems. The PMS is an important tool for controlling air pollution caused by diesel engines, helping to ensure that they meet stringent emissions standards set by regulatory bodies around the world.

Diesel Particulate Matter Sensor

A Diesel Particulate Matter (DPM) Sensor is a device used to measure the amount of particulate matter in diesel exhaust. These sensors are typically placed in the exhaust system, and are designed to detect any particles that may be emitted from the engine, including soot, unburned fuel or other pollutants. The data collected by these devices can then be used to help monitor air quality and improve emissions control systems in vehicles powered by diesel engines.

Paccar Mx 13 Pm Sensor Location

The Paccar MX 13 PM Sensor is located on the rear of the engine, near the exhaust manifold. It monitors air pressure changes inside the cylinder and transmits data to the ECM which helps regulate fuel injection timing, valve timing and spark advance. The sensor is responsible for providing accurate information about engine performance so it is important to keep it in good condition.

Conclusion

In conclusion, the Cummins Particulate Matter Sensor is an important component of diesel engines and must be correctly located for proper performance. Proper location can help to ensure that the engine runs as efficiently as possible and reduces emissions. Knowing exactly where it is located on your vehicle can help you to find it quickly if there are any issues with its operation or performance.