Cummins Isl9 Crankcase Pressure Sensor Location: Unveiling the Hidden Placement

The Cummins Isl9 crankcase pressure sensor is located on the left side of the engine, on the top. It is used to monitor the pressure of the engine oil in the crankcase and signal a warning if there are any fluctuations or if the pressure falls below or exceeds the indicated levels.

This sensor plays a crucial role in maintaining the health and performance of the engine. By accurately detecting any abnormal oil pressure, it helps prevent potential engine damage and ensures optimal functioning. Therefore, it is essential to locate and inspect the sensor regularly to ensure that it is functioning properly.

Understanding The Crankcase Pressure Sensor

Explanation of what a crankcase pressure sensor does

The Crankcase Pressure Sensor is used to monitor the pressure of the engine oil in the Crankcase, and signal a warning if there are any large fluctuations, or if the pressure falls below the minimum or above the maximum indicated pressure.

How the sensor detects fluctuations and abnormal pressure levels

The Crankcase Pressure Sensor measures the pressure in the engine’s crankcase and sends signals to the engine control unit (ECU) to detect if there are any abnormal pressure levels. It utilizes a diaphragm that bends according to the pressure, which is converted into electrical signals.

Importance of maintaining proper pressure in the engine crankcase

Maintaining proper pressure in the engine crankcase is crucial for its smooth operation. Too high or too low pressure can cause damage to the engine and affect its performance. It can lead to oil leaks, increased emissions, poor fuel economy, and potential engine failure. Thus, regularly monitoring and maintaining the proper pressure in the crankcase is essential for the longevity of the engine.

Common Issues And Fault Codes

Common issues related to the crankcase pressure sensor can lead to various fault codes being triggered. It is important to diagnose and resolve sensor-related issues promptly to ensure the proper functioning of the Cummins ISL9 engine. The crankcase pressure sensor is responsible for monitoring the pressure of the engine oil in the crankcase and providing a warning if there are any significant fluctuations or if the pressure falls below or exceeds the recommended levels. By measuring pressure, the sensor helps detect any leaks or disconnects in the positive crankcase ventilation system. One common fault code related to crankcase pressure is 0555, which indicates above-normal pressure. To resolve this issue, it is recommended to check the left side of the engine, specifically near the front of the EGR cooler, for any potential blockages. Addressing crankcase pressure sensor problems promptly can help prevent further engine damage and ensure optimal performance.

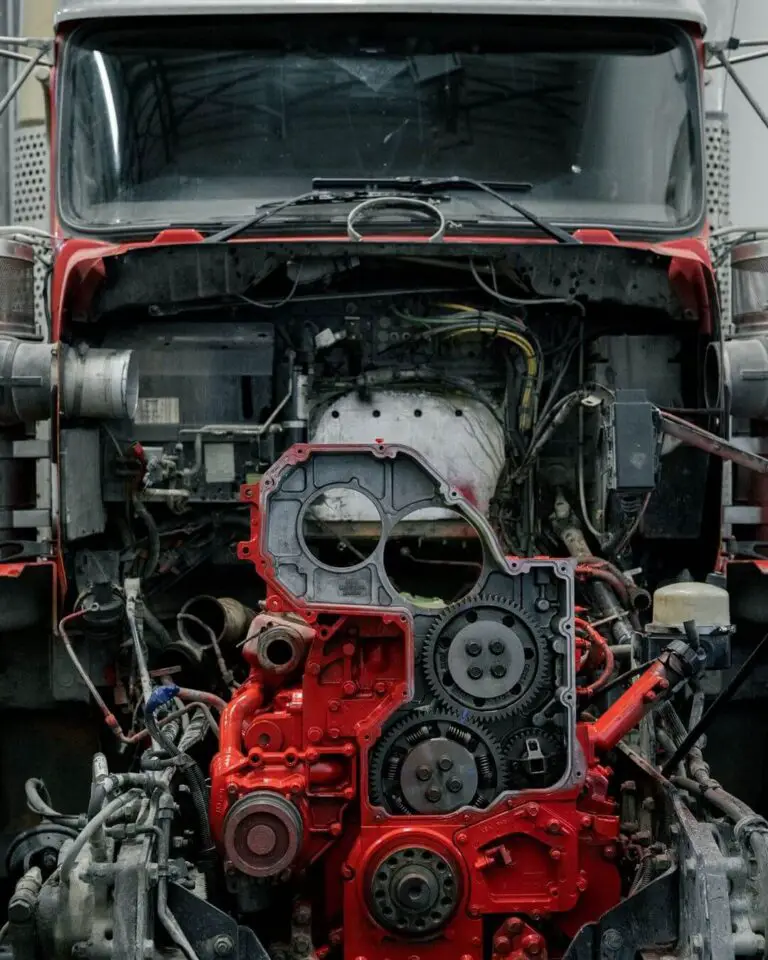

Locating The Cummins Isl9 Crankcase Pressure Sensor

When it comes to locating the Cummins Isl9 crankcase pressure sensor, there are several factors that determine its placement in the engine. The typical placement of the sensor in Cummins Isl9 engines is on the left side of the engine. It is usually located near the front of the EGR cooler or on the top view of the left side of the engine. The sensor is responsible for monitoring the pressure of the engine oil in the crankcase and signaling a warning if there are any large fluctuations or if the pressure falls below the minimum or above the maximum indicated pressure. To locate the hidden placement of the sensor, you can refer to a step-by-step guide or consult an expert in truck repair. By understanding the sensor’s location, you can ensure proper maintenance and troubleshooting of your Cummins Isl9 engine.

Tips For Accessing And Replacing The Sensor

The Cummins ISL9 Crankcase Pressure Sensor is an important component in monitoring the engine oil pressure in the crankcase. It is essential to periodically access and replace the sensor to ensure proper engine performance and avoid potential issues.

Importance Of Safety Precautions When Accessing The Sensor

Before starting any work on the sensor, it is crucial to prioritize safety precautions. Some key safety measures include:

- Wearing protective gloves and eyewear

- Ensuring the engine is turned off and cooled down before accessing the sensor

- Following proper lockout/tagout procedures

- Using appropriate tools and equipment

Tools And Equipment Needed For Sensor Replacement

When replacing the Cummins ISL9 Crankcase Pressure Sensor, you will need the following tools and equipment:

- Socket wrench set

- Torque wrench

- Replacement sensor

- Clean towels or rags for cleanup

Step-by-step Instructions For Removing And Installing The Sensor

To replace the Cummins ISL9 Crankcase Pressure Sensor, follow these steps:

- Locate the sensor, which is typically on the top of the engine and near the crankcase.

- Disconnect the electrical connector from the sensor.

- Using a socket wrench, carefully remove the sensor from its mounting position.

- Clean the area around the mounting position with a clean towel or rag.

- Install the replacement sensor by carefully screwing it into the mounting position.

- Tighten the sensor to the manufacturer’s recommended torque using a torque wrench.

- Reconnect the electrical connector to the new sensor.

- Perform a visual inspection to ensure all connections are secure and there are no signs of damage or leaks.

- Start the engine and monitor for any abnormal pressures or warning signs.

Troubleshooting Sensor Issues

Located on the left side of the engine, the Cummins ISL9 crankcase pressure sensor monitors engine oil pressure and alerts to any fluctuations or deviations from the optimal range. Easily detect and troubleshoot sensor issues for improved engine performance.

| Overview of common troubleshooting methods for sensor problems: |

| Regular sensor maintenance is crucial in ensuring accurate readings and preventing sensor-related issues. This includes inspecting the sensor for any physical damages, cleaning it regularly, and ensuring proper connections. It is also important to check for any error codes related to the sensor and address them promptly. |

| Professional tips for resolving sensor-related issues effectively: |

| When troubleshooting sensor issues, it is recommended to consult the manufacturer’s documentation or seek professional assistance. They may provide specific diagnostic procedures and troubleshooting steps for the particular sensor. Additionally, checking for any software or firmware updates for the sensor and ensuring compatibility with the system can also help resolve issues. If the problem persists, consider replacing the sensor with a new one from a reputable source. |

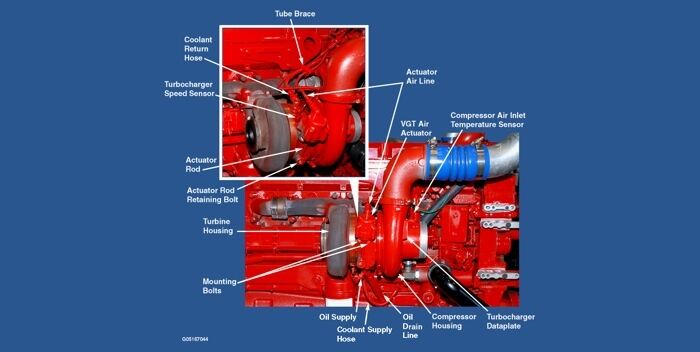

Credit: docplayer.net

Frequently Asked Questions For Cummins Isl9 Crankcase Pressure Sensor Location

What Does A Crankcase Pressure Sensor Do?

The crankcase pressure sensor monitors engine oil pressure in the crankcase. It alerts if there are pressure fluctuations or if pressure falls below or exceeds the recommended range.

What Is The Code For Crankcase Pressure Fault?

The code for a crankcase pressure fault is a diagnostic trouble code (DTC). It indicates that there is an issue with the pressure in the engine’s crankcase. It is important to address this fault as it can impact the performance and efficiency of the engine.

Seek professional help to diagnose and fix the problem.

What Does The Crankcase Ventilation Sensor Detect?

The crankcase ventilation sensor detects pressure to check for leaks or disconnects in the positive crankcase ventilation system.

What Sensor Is On Valve Cover 6.7 Cummins?

The sensor on the valve cover of a 6. 7 Cummins is a crankcase pressure sensor. It monitors the pressure of the engine oil in the crankcase and alerts if there are any fluctuations or if the pressure goes below or above the indicated limits.

Conclusion

To ensure the proper functioning of your Cummins ISL9 engine, it’s essential to be aware of the crankcase pressure sensor location. This sensor plays a crucial role in monitoring the engine oil pressure in the crankcase and alerting you to any significant fluctuations or deviations from the recommended range.

By understanding where the crankcase pressure sensor is located, you can easily inspect and maintain it for optimal engine performance. Keep your Cummins ISL9 running smoothly by familiarizing yourself with the crankcase pressure sensor’s location and ensuring its proper functioning.