Cummins Injector Metering Rail 1 Pressure Sensor Location: Uncover the Hidden Power Behind Your Engine

The Cummins Injector Metering Rail 1 Pressure Sensor is located in the high pressure fuel rail. If this sensor is not reading correctly, it can lead to symptoms such as hard starts, no starts, or inconsistent throttle response.

If you are experiencing any of these symptoms, it is recommended to replace the failed sensor with a genuine Cummins Replacement Rail Pressure Sensor.

What Is A Cummins Injector Metering Rail 1 Pressure Sensor?

What is a Cummins Injector Metering Rail 1 Pressure Sensor? The Cummins Injector Metering Rail 1 Pressure Sensor is a crucial component in the fuel system of a Cummins engine. It is responsible for measuring the fuel pressure within the injector metering rail and transmitting the information to the engine control module (ECM). The ECM then uses this data to adjust the fuel injection timing and duration, ensuring optimal engine performance and fuel efficiency.

Definition and function of the Cummins Injector Metering Rail 1 Pressure Sensor

The Cummins Injector Metering Rail 1 Pressure Sensor is a sensor that is mounted in the high-pressure fuel rail of the engine. It measures the pressure of the fuel within the rail and sends this information to the ECM. The ECM uses the data from the pressure sensor to control the fuel injection process, including adjusting the timing and duration of the fuel injections. This ensures that the engine is receiving the correct amount of fuel at the right time, resulting in optimal performance and fuel efficiency.

Importance Of The Cummins Injector Metering Rail 1 Pressure Sensor

Importance of the Cummins Injector Metering Rail 1 Pressure Sensor

Exploring the role of the Cummins Injector Metering Rail 1 Pressure Sensor in engine performance:

The Cummins Injector Metering Rail 1 Pressure Sensor is a vital component for the proper functioning of an engine. It plays a crucial role in fuel delivery and combustion efficiency. This sensor is responsible for measuring the fuel pressure in the high-pressure fuel rail and relaying the information to the engine control module (ECM).

When the sensor is functioning correctly, it ensures an optimal fuel-air mixture, resulting in efficient combustion and power generation. It helps maintain the right fuel pressure to ensure accurate fuel delivery to the injectors, preventing issues such as hard starts, inconsistent throttle response, or even engine stall.

Located in the high-pressure fuel rail, the sensor constantly monitors the fuel pressure and provides real-time data to the ECM, allowing it to make necessary adjustments for optimal engine performance. Hence, it is crucial to ensure that the Cummins Injector Metering Rail 1 Pressure Sensor is in good working condition to avoid any potential engine problems.

Locating The Cummins Injector Metering Rail 1 Pressure Sensor

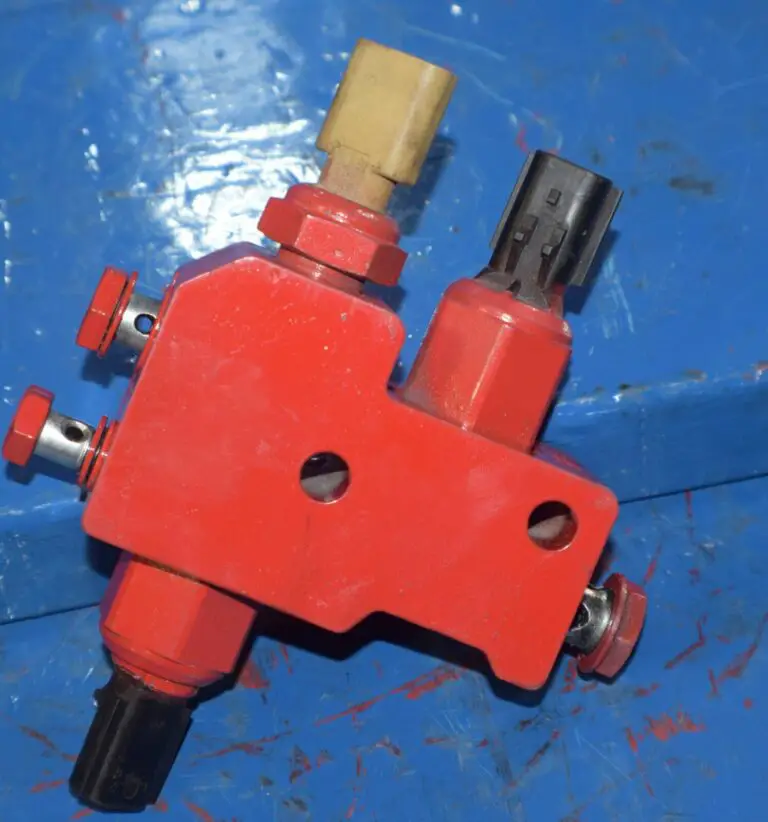

Cummins Injector Metering Rail 1 Pressure Sensor is an important component in Cummins engines. When it comes to locating this sensor, there are a few factors to consider. It is typically found in the high pressure fuel rail, specifically on the air intake side of the engine. The sensor is mounted alongside the fuel pressure relief valve which is also found on the high pressure fuel rail. Accessing the sensor may vary depending on the Cummins model, so here are some tips and tricks to help you find it in different models. If you’re experiencing symptoms such as hard starts, no starts, or inconsistent throttle response, it may indicate a problem with the rail pressure sensor. In such cases, replacing the failed sensor with a genuine Cummins Replacement Rail Pressure Sensor is recommended for optimal performance.

Credit: issuu.com

Signs Of A Faulty Cummins Injector Metering Rail 1 Pressure Sensor

If you are experiencing hard starts, no starts, or inconsistent throttle response, it may indicate a faulty Cummins Injector Metering Rail 1 Pressure Sensor. Ensure proper functioning by replacing it with a genuine Cummins Replacement Rail Pressure Sensor.

| Signs of a Faulty Cummins Injector Metering Rail 1 Pressure Sensor |

| Common symptoms indicating a malfunctioning Cummins Injector Metering Rail 1 Pressure Sensor: |

|

| How to diagnose sensor issues: |

|

| Importance of timely replacement: |

|

Replacing The Cummins Injector Metering Rail 1 Pressure Sensor

To replace the Cummins Injector Metering Rail 1 Pressure Sensor, you will need a few necessary tools and take certain precautions. Firstly, make sure to have a socket wrench, a container to catch any spilled fuel, and safety gloves on hand. Before starting, remember to wear safety glasses and disconnect the battery to prevent any electrical accidents.

Now, let’s proceed with the replacement process:

- Locate the old sensor, which is mounted on the high-pressure fuel rail of the Cummins engine.

- Remove the electrical connector by pressing the tab and gently pulling it apart.

- Next, use the socket wrench to loosen and remove the sensor from the fuel rail, taking care not to damage the threads.

- Once the old sensor is removed, replace it with a genuine Cummins Replacement Rail Pressure Sensor.

- Tighten the sensor onto the fuel rail using the socket wrench.

- Reconnect the electrical connector until it snaps into place.

Troubleshooting Common Issues With The Cummins Injector Metering Rail 1 Pressure Sensor

When it comes to troubleshooting common issues with the Cummins Injector Metering Rail 1 Pressure Sensor, it is important to address problems such as hard starts, no starts, and inconsistent throttle response. If this sensor is not reading correctly, you may experience these symptoms. In such cases, it is recommended to replace the failed sensor with a genuine Cummins Replacement Rail Pressure Sensor. Other possible causes for these issues could include a failed lift pump, plugged injector, or out-of-date ECM calibration. The fuel pressure sensor is mounted in the high-pressure fuel rail, while the fuel pressure relief valve is also mounted on the high-pressure fuel rail. It is crucial to ensure that these components are functioning properly for optimal performance of the Cummins engine.

Maintenance And Care Tips For The Cummins Injector Metering Rail 1 Pressure Sensor

The Cummins Injector Metering Rail 1 Pressure Sensor is a crucial component for the optimal performance of your vehicle. To ensure its longevity and proper functionality, it is important to follow some maintenance and care tips:

- Regularly clean and inspect the sensor for any dirt or debris that may affect its readings. Use a mild cleanser and a soft cloth to clean the sensor gently.

- Inspect the sensor at regular intervals to check for any signs of wear or damage. If you notice any issues, such as cracks or leaks, it is advisable to replace the sensor.

- Follow the manufacturer’s guidelines for inspection intervals and maintenance procedures. This will help in identifying any potential issues and address them promptly.

By following these best practices, you can ensure the longevity and optimal performance of the Cummins Injector Metering Rail 1 Pressure Sensor in your vehicle.

Frequently Asked Questions For Cummins Injector Metering Rail 1 Pressure Sensor Location

What Are The Symptoms Of The Cummins Rail Pressure Sensor?

If the Cummins rail pressure sensor is not reading correctly, you may experience hard starts, no starts, or inconsistent throttle response. To fix these symptoms, replace your failed sensor with a genuine Cummins Replacement Rail Pressure Sensor.

What Is The Code 559 On The Cummins Injector Metering Rail 1 Pressure?

Code 559 on the Cummins injector metering rail 1 pressure indicates a fault with the fuel rail pressure sensor. This can result in symptoms like hard or no starting, and inconsistent throttle response. If experiencing these issues, it is recommended to replace the failed sensor with a genuine Cummins Replacement Rail Pressure Sensor.

How Do I Know If My Fuel Rail Pressure Sensor Is Bad?

If your fuel rail pressure sensor is bad, you may experience symptoms such as hard starts, no starts, or inconsistent throttle response. If you notice any of these issues, it’s recommended to replace the sensor with a genuine Cummins Replacement Rail Pressure Sensor.

What Is The Code For The Cummins Metering Rail?

The code for the Cummins metering rail is not specified in the provided information.

Conclusion

If you are experiencing issues such as hard starts, no starts, or inconsistent throttle response, it could be due to a faulty Cummins Injector Metering Rail 1 Pressure Sensor. This sensor is typically located in the high pressure fuel rail and plays a crucial role in delivering the right amount of fuel to your engine.

If you suspect a problem with this sensor, it is important to replace it with a genuine Cummins Replacement Rail Pressure Sensor. By doing so, you can ensure proper fuel delivery and avoid further complications. Trusting reliable diagnostics and professional assistance can help you address this issue effectively.