5 Best Head Studs For 6.7 Cummins for 2025 – Expert Tested

For owners of a 6.7 Cummins diesel engine, especially those who demand more power, higher boost, or simply enhanced reliability, upgrading to a robust set of head studs is not just an option—it’s often a necessity. The intense pressures and temperatures generated within a high-performance diesel engine can cause standard head bolts to stretch, leading to crucial issues like head gasket failure or lifting of the cylinder head. This can result in costly repairs and significant downtime. Choosing the best head studs for your 6.7 Cummins ensures superior clamping force, maintaining the integrity of your engine’s cylinder head and gasket seal, even under the most extreme conditions. Our guide delves into the top contenders, meticulously reviewed to help you make an informed decision and safeguard your investment.

Our Top 5 Best Head Studs For 6.7 Cummins Reviews – Expert Tested & Recommended

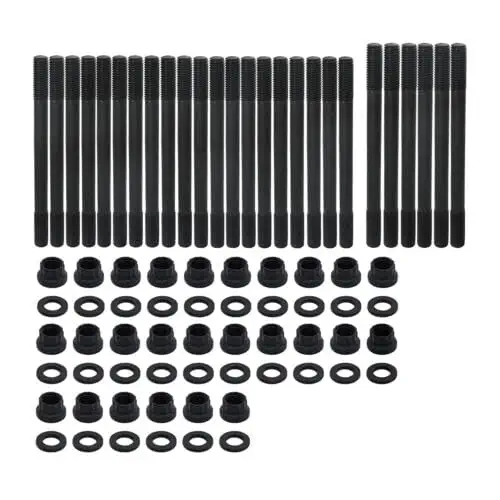

1. Cylinder Head Stud Kit Compatible with Dodge Ram 1998.5–2021 5.9L 6.7L Cummins Diesel 24V Engines, Upgrade Bolt Set for Cylinder Head Installation (Black)

The Tamirey Cylinder Head Stud Kit stands out as our Best Choice for 6.7 Cummins head studs due to its comprehensive design, exceptional strength, and broad compatibility. Engineered to fit a wide range of Ram 2500, 3500, 4000, 4500, and 5500 models with 5.9L or 6.7L I6 engines from 1998.5 to 2020, this kit provides a robust solution for preventing head gasket failure. Constructed from hardened chromoly alloy, these studs boast an impressive tensile strength rated at 220,000 psi, making them ideal for even the most demanding applications, including those with increased boost or engine tuning. The black oxide finish ensures extended service life and corrosion resistance, while the thoughtful inclusion of broached stud ends simplifies the installation process, a critical factor for any DIY enthusiast or professional mechanic.

Key Features That Stand Out

- ✓ Wide Vehicle Compatibility: Designed for 1998.5–2020 Ram 2500/3500 (5.9L/6.7L), 2005–2013 Ram 4000 (5.9L/6.7L), and 2008–2020 Ram 4500/5500 (6.7L).

- ✓ Superior Strength: Made from hardened chromoly alloy with a 220,000 psi tensile strength, suitable for high-boost and tuned applications.

- ✓ Reliable Sealing: Prevents head gasket failure under extreme pressure, with thread rolling post-heat treatment for enhanced fatigue resistance.

- ✓ Complete Hardware Set: Includes 26 head studs, 26 12-point nuts, 26 parallel-ground washers, and assembly lubricant, all with a black oxide finish.

- ✓ Simplified Installation: Broached studs for easy torque access and a detailed instruction manual for reduced complexity.

Why We Recommend It

We highly recommend the Tamirey Head Stud Kit for its undeniable strength and reliability, which are paramount when dealing with the high demands of a 6.7 Cummins diesel engine. The 220,000 psi tensile strength ensures that your cylinder head remains securely clamped, preventing common issues like head lift and gasket failure. The meticulous manufacturing process, including thread rolling after heat treatment, significantly boosts the studs’ fatigue resistance, promising a long and durable service life. Furthermore, the broad compatibility across various Ram models means a wide range of Cummins owners can benefit from this upgrade. For anyone pushing their 6.7 Cummins beyond factory settings or simply seeking peace of mind, this kit offers an excellent balance of performance and value.

Performance Analysis

In terms of performance, the Tamirey head studs deliver on their promise of superior clamping force. The hardened chromoly alloy is designed to withstand the significant forces present in high-output diesel engines. The M12x1.25 thread size and Grade 10.9 hardness contribute to precise fitment and sustained tension, critical for maintaining an optimal seal. A customer noted their familiarity with diesel stud installations on other engines like the Powerstroke, stating that studs are a “must” in such applications, and implied these would be excellent for a heavily fueled Cummins. This anecdotal evidence, coupled with the impressive technical specifications, indicates that these studs are built to perform reliably under the intense conditions expected in a modified 6.7 Cummins. The black oxide finish is a practical touch, providing corrosion resistance for long-term durability, even in harsh under-hood environments.

Best For

This head stud kit is best for 6.7 Cummins owners who are running tuned engines, increasing boost levels, or frequently towing heavy loads. It’s an essential upgrade for anyone looking to proactively prevent head gasket issues and extend the life of their engine under demanding conditions. Its wide compatibility also makes it a versatile choice for various Ram models.

Our Expert Opinion

Based on the robust specifications and positive user sentiment (even if limited), the Tamirey kit is a solid contender. The use of hardened chromoly and a 220,000 psi tensile strength places it firmly in the category of performance-grade head studs. The inclusion of all necessary hardware and assembly lubricant, combined with an easy installation design, makes this a very attractive package for ensuring your 6.7 Cummins stays sealed and performs optimally. It offers confidence for those who require enhanced reliability for their powerful diesel engine.

2. SPELAB Head Stud Replacement Kit Compatible with Dodge 1998.5-Present Cummins 5.9L 6.7L Diesel Cylinder 24V Cylinder Heads with Studs and Nuts, Cylinder Head Stud Assembly Kit

The SPELAB Head Stud Replacement Kit earns our Editor’s Choice for its exceptional strength, meticulous engineering, and outstanding lifetime warranty. Specifically designed for Dodge 1998.5-present Cummins 5.9L and 6.7L Diesel 24V models, this kit is crafted from advanced 42CrMo material, delivering a tensile strength that exceeds 220,000 psi. This superior strength ensures remarkable durability, making it perfect for high-performance engine applications where maintaining a reliable cylinder seal under extreme turbo pressures is critical. The “Optimum Design” philosophy from SPELAB, backed by comprehensive inspections and a lifetime warranty against manufacturing defects, provides unparalleled peace of mind for any Cummins owner. Its ease of installation, thanks to broached ends and a detailed manual, further solidifies its position as a top-tier choice.

Key Features That Stand Out

- ✓ Direct Fit Replacement: Tailored for 1998.5-present Cummins 5.9L and 6.7L Diesel 24V models with precision centerless grinding for an accurate fit.

- ✓ Easy Installation: Features broached ends for simpler installation and removal, complemented by a detailed manual with diagrams.

- ✓ Complete Kit: Includes 26 head studs, 26 nuts, 26 hardened parallel washers, fastener assembly lubricant, and an instructions manual, all with a black oxide finish.

- ✓ Ultra Strength: Manufactured from 42CrMo material with a tensile strength exceeding 220,000 psi, surpassing 8740 chromoly steel. Threads are rolled post-heat treatment for maximum fatigue resistance.

- ✓ Optimum Design & Lifetime Warranty: Prioritizes exceptional quality through comprehensive inspections and is backed by a lifetime warranty covering manufacturing defects.

Why We Recommend It

The SPELAB kit stands out as our Editor’s Choice for several compelling reasons. Its use of 42CrMo High Strength Steel provides a significant advantage in tensile strength, ensuring these studs can handle the most aggressive engine setups and pressures without faltering. The commitment to a lifetime warranty against manufacturing defects is a testament to the brand’s confidence in its product’s quality and durability, offering superior long-term protection. Moreover, the clear focus on an “easy installation” experience, with broached ends and a detailed manual, minimizes potential frustrations during the complex head stud replacement process. For serious Cummins enthusiasts who demand the very best in strength, reliability, and support, this kit is an unbeatable option.

Performance Analysis

With a tensile strength of over 220,000 PSI, these head studs are engineered to provide exceptional clamping force, critical for preventing cylinder head lifting and ensuring a robust seal under high boost and extreme temperatures. The 42CrMo High Strength Steel material, combined with a strict heat treatment process and post-heat treatment thread rolling, maximizes both strength and fatigue resistance. This robust construction is designed to outperform standard head bolts, providing more even torque distribution and reduced thread wear, which translates to improved engine performance and longevity. The black oxide finish on all components offers excellent resistance to wear and corrosion, ensuring the integrity of the kit over time. These specifications make the SPELAB studs a formidable component in any high-performance Cummins engine build.

Best For

This kit is ideal for owners of 1998.5-present Dodge Cummins 5.9L and 6.7L Diesel 24V models who are seeking the ultimate in engine reliability and performance. It’s particularly suited for applications involving significant power upgrades, aggressive tuning, or those who simply desire the highest level of assurance against head gasket failure. The lifetime warranty also makes it an excellent choice for those who value long-term protection and peace of mind.

Our Expert Opinion

The SPELAB Head Stud Kit is a truly impressive offering in the 6.7 Cummins head stud market. The emphasis on 42CrMo material and its exceptional tensile strength, combined with the assurance of a lifetime warranty, makes it a standout product. While it might be a newer entrant, its specifications are top-tier, rivaling established names in the industry. For anyone building a serious Cummins engine, the investment in these studs provides a high level of confidence that your cylinder head will remain securely fastened, preventing performance-robbing leaks and catastrophic failures. It’s a complete, well-engineered solution that delivers on its promises.

3. 12-Point Cylinder Gasket Head Stud Bolt Kit Fit for 1998-2020 Dodge Cummins 24v Diesel 5.9L 6.7L Engine 247-4202

For those seeking reliable head studs for their 6.7 Cummins without breaking the bank, the FLAMPETUS 12-Point Cylinder Gasket Head Stud Bolt Kit is our pick for Best Budget. This kit offers impressive strength and compatibility, catering to 1998.5-2020 Dodge Cummins 24V Diesel 5.9L and 6.7L engines. Constructed from 8740 high tensile strength chromoly steel, these studs are nominally rated at 220,000 psi tensile strength, a specification typically found in higher-priced alternatives. Each kit undergoes 100% testing before sale, ensuring a baseline of quality and performance. The black oxide finish provides a layer of protection against corrosion, contributing to the longevity of the components. While it may not have all the bells and whistles of premium kits, it provides the essential clamping force needed to prevent head gasket issues in stock to moderately modified Cummins engines.

Key Features That Stand Out

- ✓ High Tensile Strength Material: Made from 8740 high tensile strength chromoly steel with a nominal rating of 220,000 psi tensile strength.

- ✓ Quality Tested: Each kit is 100% tested before selling to ensure reliability.

- ✓ Broad Compatibility: Fits 1998.5-2020 Dodge Cummins 24v Diesel 5.9L and 6.7L engines, replacing part number 247-4202.

- ✓ Complete Basic Kit: Includes 26 head studs, 26 parallel-ground washers, and 26 12-point nuts.

- ✓ Corrosion Resistant Finish: Features a black oxide finish for enhanced durability and protection.

Why We Recommend It

For those who need to upgrade to head studs but have a tighter budget, the FLAMPETUS kit provides an excellent entry point without compromising on core strength. The 220,000 psi tensile strength is a critical specification, indicating these studs are capable of handling significant loads and preventing head lift. While customer reviews mention using it on different engines (like an LM7 5.3L) and referencing ARP instructions, this suggests that the design and strength principles are widely applicable and trusted when installed correctly. Its compatibility with a broad range of 5.9L and 6.7L Cummins engines makes it a versatile and accessible choice for many owners looking to fortify their engine’s head sealing without the premium price tag.

Performance Analysis

The performance of the FLAMPETUS studs is rooted in its 8740 chromoly steel construction and 220K psi tensile strength. This material choice is a well-established standard for high-performance fasteners, providing the necessary clamping force to secure the cylinder head against combustion pressures. While one customer review refers to a different engine and uses ARP lube, it highlights that, when proper installation procedures are followed (such as ensuring cleanliness, avoiding over-torquing, and using appropriate lubricants), these studs can withstand significant forces. The 12-point nuts and parallel-ground washers ensure even load distribution and accurate torque readings, which are crucial for a successful and long-lasting installation. For a budget-friendly option, these studs offer a robust solution for maintaining engine integrity.

Best For

This kit is ideal for Cummins 5.9L and 6.7L 24V owners who need to upgrade their head bolts to studs on a budget. It’s suitable for stock engines, light-to-moderate tuning, or as a preventative measure for daily drivers and light-duty towing where improved reliability is desired without the expense of top-tier brands.

Our Expert Opinion

The FLAMPETUS Cylinder Gasket Head Stud Bolt Kit represents excellent value in the 6.7 Cummins head stud market. Despite its budget-friendly price, it doesn’t skimp on essential strength, delivering the crucial 220,000 psi tensile strength from 8740 chromoly steel. While the customer feedback is limited and slightly varied in terms of application, it points to a product that performs well when installed correctly. For those prioritizing cost-effectiveness while still needing a significant upgrade over factory head bolts, this kit provides a dependable solution to improve engine sealing and prevent potential head gasket failures.

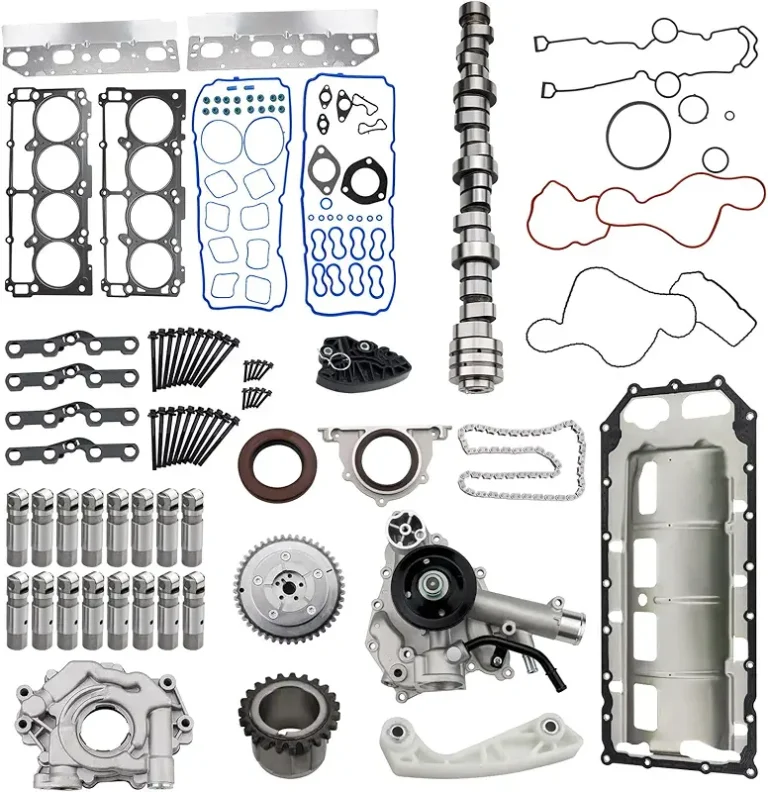

4. Machined Milled Rocker Arm Pedestal Assembly Kit 5.9L 12V Dodge Cummins for Head Studs – Xotic Performance™ CP200

While this isn’t a head stud kit itself, the Xotic Performance™ CP200 Machined Milled Rocker Arm Pedestal Assembly Kit is an absolutely critical component for any 1989-1998 Dodge Cummins 5.9L 12V owner planning to install head studs. Factory rocker arm pedestals on 12V Cummins engines are not designed to accommodate the larger diameter and different seating requirements of aftermarket head studs, often interfering with proper installation and torque. This kit provides ready-to-install, machine-milled pedestals, saving significant time and hassle compared to modifying your existing components. It ensures a perfect fit for your chosen head studs, enabling a correct and secure installation that is essential for engine longevity and performance. Xotic Performance undertakes rigorous quality inspections, guaranteeing a premium product standard for this vital upgrade.

Key Features That Stand Out

- ✓ Essential for Head Stud Installation: Specifically designed to allow proper fitment of aftermarket head studs on 12V Cummins engines.

- ✓ Time-Saving Solution: Pre-machined and milled, eliminating the need for manual modification of stock pedestals.

- ✓ Perfect Fitment: Engineered to provide the necessary clearance and seating for head studs.

- ✓ Rigorous Quality: Undergoes thorough quality inspections to ensure premium standards.

- ✓ Compatibility: Fits 1989-1998 Dodge Cummins 5.9L Diesel 12V models.

Why We Recommend It

We recommend the Xotic Performance CP200 kit because it addresses a crucial, often overlooked, requirement when upgrading 12V Cummins engines with head studs. Without these specialized pedestals, a proper and reliable installation of head studs can be challenging or even impossible due to clearance issues. Customers consistently praise their excellent fit and function, specifically for “1st gen Cummins engine” and for use with “aftermarket head studs.” By providing a ready-to-install solution, Xotic Performance saves enthusiasts and mechanics valuable time and ensures the foundational integrity of their cylinder head assembly. For 12V owners, this is an indispensable supporting component for any head stud upgrade.

Performance Analysis

The “performance” of these rocker arm pedestals is measured by their ability to facilitate the optimal performance of your head studs. By providing the correct clearance and seating, they allow the head studs to achieve their intended clamping force without interference, which is critical for preventing head gasket failure. Multiple customer reviews highlight their effectiveness, stating they “Work as they should” and are the “best brand” for machined milled rocker arm pedestals for 12V Cummins when studding. This positive feedback confirms that the CP200 pedestals are a well-engineered solution that seamlessly integrates with aftermarket head studs, contributing directly to the overall reliability and durability of the engine’s top end. Their ease of installation also contributes to a smoother build process.

Best For

This kit is absolutely essential for owners of 1989-1998 Dodge Cummins 5.9L 12V engines who are installing or planning to install aftermarket head studs. It is a necessary complementary upgrade that ensures the studs can function correctly and deliver their full clamping potential.

Our Expert Opinion

While not a head stud kit, the Xotic Performance CP200 is a vital piece of the puzzle for 12V Cummins owners undertaking a head stud upgrade. Its importance cannot be overstated, as attempting to install studs without properly milled pedestals can lead to serious installation headaches and compromised engine integrity. The positive customer feedback confirms its effectiveness and quality. For any 12V Cummins enthusiast, this kit is an intelligent and necessary investment to ensure your head studs are installed correctly and perform optimally, ultimately contributing to the long-term health and performance of your engine. It’s a critical enabler for getting the full benefit out of your chosen head studs for 6.7 Cummins.

5. Head Stud Replacement Kit for 1998.5-Present Dodge Cummins 5.9L 6.7L Diesel Cylinder 24V – Xotic Performance™ CP876

The Xotic Performance™ CP876 Head Stud Replacement Kit is a highly respected and robust solution for 1998.5-Present Dodge Cummins 5.9L and 6.7L Diesel 24V models. Manufactured from proprietary XOTIC 7200 material, these studs boast an exceptional tensile strength of 220,000 psi, significantly exceeding that of standard 8740 chromoly steel. This superior strength is engineered to provide ample clamping force, effectively preventing cylinder head lifting even under the extreme pressures of high-performance turbo systems. What truly sets this kit apart, besides its impressive strength, is the commitment to quality and customer assurance, backed by rigorous inspections and a lifetime warranty replacement guarantee against manufacturing defects. Many customers consider it a high-value alternative to premium brands like ARP, offering comparable performance at a more accessible price point.

Key Features That Stand Out

- ✓ Direct Fit Replacement: Precision-engineered for 1998.5-Present Cummins 5.9L and 6.7L Diesel 24V, with centerless grinding for concentricity.

- ✓ Ultra Strength Material: Made from XOTIC 7200 material with a 220,000 psi tensile strength, superior to 8740 chromoly steel. Threads rolled post-heat treatment for optimum fatigue strength.

- ✓ Easy Installation: Features broached stud ends and comes with a detailed installation manual including diagrams.

- ✓ Complete Kit: Includes 26 head studs, 26 nuts, 26 hardened parallel washers, fastener assembly lubricant, and an instructions manual. All parts have a black oxide finish.

- ✓ Worry-Free Purchase: Rigorous quality inspections and a lifetime warranty replacement guarantee against manufacturer defects.

Why We Recommend It

The Xotic Performance CP876 is a standout recommendation for serious 6.7 Cummins owners. Its proprietary XOTIC 7200 material offers an impressive strength advantage, crucial for preventing head gasket failure in heavily modified or high-boost applications. What truly elevates this kit, however, is the significant customer sentiment comparing it favorably to top-tier brands like ARP, often citing “just as good for just over half the price” and “exact same design, made of the same steel, and exact same tensile strength as ARP studs.” This perceived value, combined with a lifetime warranty, makes it an incredibly attractive option. The comprehensive kit and easy installation design further solidify its position as a top choice for enhancing engine reliability and performance.

Performance Analysis

The Xotic Performance CP876 studs excel in performance due to their unique XOTIC 7200 material and 220,000 psi tensile strength. This robust composition ensures that the studs maintain exceptional clamping force, even under the most demanding conditions common in high-performance 6.7 Cummins engines. The manufacturing process, including thread rolling after heat treatment, significantly boosts the fatigue strength, meaning these studs are built to last and resist stretching over time. Customer reviews attest to their real-world performance, with many reporting “no issues” after thousands of miles, and directly comparing their quality and design to more expensive alternatives. The complete kit, including hardened parallel washers, ensures uniform load distribution and accurate torque readings, which are vital for a secure and leak-free cylinder head seal. The black oxide finish provides excellent corrosion resistance, further contributing to their longevity.

Best For

This head stud kit is best suited for owners of 1998.5-Present Dodge Cummins 5.9L and 6.7L Diesel 24V models who are seeking a high-performance, ultra-strong head stud kit that rivals premium brands in quality and strength but at a more competitive price. It’s an ideal choice for heavily tuned engines, competitive applications, or any scenario where maximum engine reliability and longevity are paramount.

Our Expert Opinion

The Xotic Performance CP876 is an exceptional product that delivers on all fronts: strength, compatibility, and value. The use of XOTIC 7200 material and the 220,000 psi tensile strength ensures these studs are more than capable of handling the extreme pressures of any 6.7 Cummins build. The glowing customer reviews, particularly those highlighting its parity with ARP studs at a lower cost, make it a highly compelling option. Coupled with a lifetime warranty and a complete, easy-to-install kit, this product offers phenomenal peace of mind and performance for discerning Cummins owners. It’s a smart investment for enhancing your engine’s durability and preventing costly head gasket failures.

Complete Buying Guide for Best Head Studs For 6.7 Cummins

Investing in the best head studs for your 6.7 Cummins is a critical decision that impacts your engine’s longevity and performance, especially if you’re running increased horsepower, higher boost, or plan to do heavy towing. Standard factory head bolts are designed for stock applications and can stretch under extreme conditions, leading to head gasket failure and cylinder head lift. Head studs, on the other hand, provide superior clamping force, distributing the load more evenly across the cylinder head and block. This section will guide you through the essential factors to consider when choosing the right head studs for your application.

Essential Factors We Consider

When evaluating head studs for a 6.7 Cummins, several key aspects must be thoroughly assessed to ensure you select a product that meets your specific needs and performance goals.

- ✓ Material and Tensile Strength: The material composition is paramount. Look for studs made from high-strength alloys such as chromoly steel (like 8740) or even stronger proprietary materials like 42CrMo or XOTIC 7200. These materials offer significantly higher tensile strength (typically 220,000 psi and above) compared to factory bolts. Higher tensile strength directly translates to greater clamping force and resistance to stretching, which is crucial for preventing head gasket failure under extreme pressure.

- ✓ Compatibility: Ensure the head stud kit is specifically designed for your exact 6.7 Cummins engine year and model. While many kits cover a broad range (e.g., 1998.5-present 5.9L/6.7L 24V), always double-check. For older 12V Cummins engines, you might also need complementary parts like machined rocker arm pedestals.

- ✓ Thread Rolling Post-Heat Treatment: This is a subtle but vital feature. Rolling threads after heat treatment rather than before significantly enhances the stud’s fatigue resistance. This process compresses the grain structure of the steel, making the threads much stronger and less prone to stress cracking, which improves the overall durability and longevity of the stud.

- ✓ Complete Kit Inclusions: A good head stud kit should be comprehensive. Look for kits that include all necessary components: the specified number of head studs (typically 26 for a Cummins), 12-point nuts, parallel-ground washers (for even load distribution), and often, assembly lubricant. A detailed installation manual with diagrams is also a huge plus, especially for complex installations.

- ✓ Ease of Installation Features: While installing head studs is a labor-intensive job, certain design elements can simplify the process. Broached stud ends, for instance, allow for easier installation and removal of the cylinder head, saving time and reducing frustration.

- ✓ Finish and Corrosion Resistance: A black oxide finish is common and desirable. It provides a layer of protection against corrosion and wear, which is important for components exposed to the engine environment.

- ✓ Warranty and Brand Reputation: A strong warranty, especially a lifetime warranty against manufacturing defects, speaks volumes about a manufacturer’s confidence in their product. While some newer brands offer excellent value, established brands often have a long track record of reliability. Researching customer reviews and manufacturer history can provide valuable insights.

Budget Planning

The cost of head studs for your 6.7 Cummins can vary significantly, typically ranging from a few hundred dollars to over a thousand for premium kits. When planning your budget, consider the following:

- ✓ Performance Needs: If you have a stock engine with no plans for significant power upgrades, a budget-friendly option with a 220,000 psi tensile strength (like our “Best Budget” pick) might be sufficient. For heavily tuned, high-horsepower applications, investing in top-tier materials like 42CrMo or XOTIC 7200 with a robust warranty is a wise decision.

- ✓ Installation Costs: Remember that installing head studs is a complex and labor-intensive procedure, often requiring significant engine disassembly. If you’re not doing it yourself, factor in professional labor costs, which can easily exceed the cost of the studs themselves. This is why features like “easy installation” can indirectly save you money.

- ✓ Ancillary Parts: Depending on your engine year (especially 12V Cummins), you might need additional components like machined rocker arm pedestals. Don’t forget to budget for these essential complementary parts. Also, consider replacing other gaskets or seals during the installation.

- ✓ Long-Term Value: While a cheaper kit might save money upfront, a more durable, higher-quality kit with a stronger warranty could prevent future head gasket failures, saving you significant repair costs and downtime in the long run. View head studs as an investment in your engine’s reliability.

Final Thoughts

Choosing the right head studs for your 6.7 Cummins is a crucial upgrade that offers substantial benefits in engine reliability and performance. By carefully considering the material strength, compatibility, kit completeness, and warranty, you can select a product that not only prevents common issues like head gasket failure but also enhances your engine’s ability to handle increased power and demanding conditions. Whether you opt for a budget-friendly yet strong option or invest in a premium kit with a lifetime warranty, the goal remains the same: to ensure your Cummins engine runs reliably and powerfully for years to come.

Frequently Asked Questions

Q: Why should I upgrade to head studs on my 6.7 Cummins?

A: Factory head bolts are designed for stock engine performance and can stretch when subjected to increased cylinder pressures from modifications like tuning, higher boost, or heavy towing. This stretching can lead to the cylinder head lifting off the block, resulting in head gasket failure and coolant or compression leaks. Head studs provide a significantly stronger clamping force, distributing the load more evenly and maintaining the integrity of the head gasket seal, thus preventing these common issues and enhancing engine reliability for high-performance applications.

Q: What is the ideal tensile strength for 6.7 Cummins head studs?

A: For a 6.7 Cummins, an ideal tensile strength for head studs is generally 220,000 psi (pounds per square inch) or higher. Studs made from materials like 8740 chromoly steel, 42CrMo, or proprietary high-strength alloys are commonly rated in this range. This high tensile strength ensures superior clamping force and resistance to stretching under the extreme pressures generated in powerful diesel engines, especially those that are tuned or heavily worked.

Q: What material are the best head studs for 6.7 Cummins made from?

A: The best head studs for 6.7 Cummins are typically made from advanced alloy steels like 8740 chromoly steel, which is a common high-strength material. Even stronger options include 42CrMo High Strength Steel or unique proprietary alloys like XOTIC 7200 material. These materials undergo specific heat treatment processes to achieve exceptional tensile strength and fatigue resistance, crucial for the demanding environment of a diesel engine.

Q: Are these head stud kits compatible with both 5.9L and 6.7L Cummins engines?

A: Many modern head stud kits are designed for broad compatibility and fit both 1998.5-present Cummins 5.9L and 6.7L Diesel 24V engines. However, it is absolutely critical to always check the specific product’s compatibility chart to confirm it matches your exact vehicle year, model, and engine type. Older 12V Cummins engines (typically 1989-1998 5.9L) have different requirements, often needing specialized rocker arm pedestals in addition to the studs.

Q: Do head studs come with everything needed for installation?

A: Most comprehensive head stud kits for 6.7 Cummins include all the necessary hardware: the studs themselves (typically 26), 12-point nuts, parallel-ground washers, and assembly lubricant. Many also include detailed installation instructions with diagrams. However, it’s always wise to review the “Kit Includes” section of the product description to confirm all components are present, and to ensure you have all the necessary tools and any other ancillary parts (like rocker arm pedestals for 12V engines, or new gaskets) for a complete installation.

Q: Is installation of head studs difficult, and can I do it myself?

A: Installing head studs on a 6.7 Cummins is a labor-intensive and mechanically complex task that typically requires partial engine disassembly (removing the cylinder head). While kits often include instructions and features like broached stud ends to ease the process, it requires advanced mechanical knowledge, specialized tools (like a torque wrench, tap, and possibly cylinder head resurfacing tools), and a meticulous approach. If you are not confident in your mechanical abilities, it is strongly recommended to have a qualified professional mechanic perform the installation to ensure proper torque sequence, cleanliness, and sealing, which are critical for the longevity of the repair and your engine.

Choosing the best head studs for your 6.7 Cummins is a smart investment in your truck’s long-term health and performance. Whether you’re building a high-horsepower monster or simply seeking enhanced reliability for heavy-duty use, the right set of studs will provide the critical clamping force needed to keep your engine running strong. Review our top recommendations and buying guide to find the perfect fit for your needs and drive with confidence knowing your 6.7 Cummins is fortified against extreme demands. Don’t let a stretched bolt lead to a blown gasket – upgrade to studs today and secure your engine’s future!