Briggs And Stratton 17.5 Hp Engine Torque Specs

The Briggs and Stratton 17.5 HP engine has a torque specification of 18.3 lb-ft at 2600 RPM (revolutions per minute). The peak power output for this engine is 37 horsepower, which can reach its maximum level at 3300 RPM. This engine also has a displacement of 0.31 liters and an oil capacity of 1 liter.

The cylinder bore size is also 2 inches with a stroke length of 2.0625 inches while the compression ratio stands at 8:1. It comes equipped with electronic ignition and fixed speed governor, thus making it suitable for lawnmowers, generators or other similar applications that require reliable performance in challenging conditions.

The Briggs and Stratton 17.5 HP engine is a powerful machine, offering superior torque specs that make it ideal for heavy-duty tasks like mowing the lawn or towing large loads. This engine features a maximum torque of up to 26.0 ft-lbs at 3600 rpm, with a displacement of 479cc and an overhead valve design which helps maximize its performance capabilities. The high power output ensures plenty of speed and dexterity when tackling difficult tasks as well as providing smooth operation thanks to its advanced technology.

With this reliable engine in your yard care arsenal, you can trust that every job will be done quickly and efficiently!

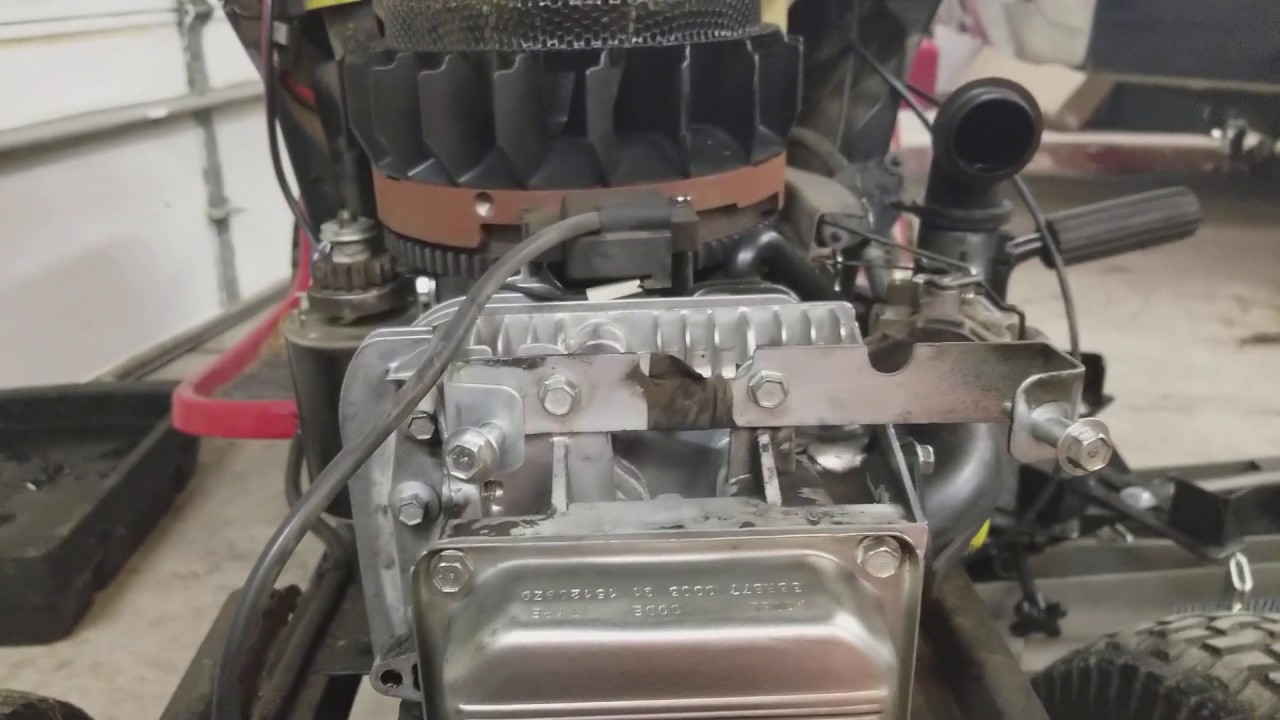

How to Adjust Valve Lash & on the Briggs & Stratton 17.5hp OHV Engine – Craftsman Lt Lawn Tractors

What to Torque Head Bolts on Briggs And Stratton Engine?

When it comes to installing or replacing head bolts on a Briggs and Stratton engine, the best practice is to torque them correctly. It’s important to use the proper tool for the job—a quality torque wrench that can be accurately calibrated is essential here. To ensure accuracy, make sure you read and follow all of the manufacturer’s directions when using your torque wrench.

The recommended settings vary depending on your particular model of engine but generally range from 24-28 Nm (17-21 lb-ft) for single cylinder engines and 33-37 Nm (25-27 lb ft) for twin cylinder engines. Additionally, be sure to check your owner’s manual for specific instructions as certain models may require different torques than those mentioned above. Finally, when tightening head bolts on a Briggs & Stratton engine you should always tighten them in an alternating pattern so there won’t be any uneven pressure applied across the surface of your gasket sealer; this will help prevent leaks from occurring down the road due to improper installation or sealing techniques.

Taking these steps when torquing head bolts will ensure that your engine runs efficiently and safely for years to come!

What is Torque Briggs And Stratton?

Torque is a measure of rotational force generated by an engine, and Briggs and Stratton are two of the world’s most popular engine manufacturers. Torque from a Briggs and Stratton engine is produced when fuel combusts inside the combustion chamber, converting it into usable energy. This process forces pistons to move up and down, creating mechanical power that can be used to propel vehicles or other machines.

The torque rating for any given Briggs & Stratton engine depends on its displacement (the total volume of air/fuel mixture consumed per cycle) as well as its compression ratio (the amount of compression during each cycle). Higher displacements generally yield higher torque ratings; similarly, higher compression ratios also lead to increased torque output. As such, larger engines tend to have greater torque potential than their smaller counterparts do.

What is the Torque Spec for Tightening Cylinder Head Bolts?

When tightening cylinder head bolts, it is important to use the correct torque specification. This will ensure that the head gasket and other components are properly sealed and do not become loose over time. The typical torque spec for most vehicles is between 20 ft-lbs (27 Nm) to 25 ft-lbs (34 Nm).

It is always best to check with the manufacturer’s specifications for your specific vehicle as there may be slight variations depending on year, make, and model. Additionally, in some cases you may need to re-torque the head bolts after an initial period of operation. For example, if a car has been driven for several hundred miles or more since its first startup then it is recommended that you retighten all of the cylinder head bolts at least once before continuing normal operation.

Make sure you follow any additional instructions provided by your vehicle’s manufacturer when replacing or adjusting cylinder heads so that everything remains safe and secure during operation.

What is the Torque on a Briggs And Stratton Carburetor Bolt?

When it comes to torque on a Briggs and Stratton carburetor bolt, the specifications vary depending on the model. Generally speaking, there should be between 8-12 foot-pounds of torque applied to the carburetor bolts when installing or replacing them. It is important to use a high quality wrench when applying this amount of torque in order to ensure that you don’t strip out the threads in your engine block from over tightening.

Additionally, lubricating all fasteners with anti-seize compound can help prevent galling and seizing during installation as well. Be sure not to exceed 12 foot pounds of torque as doing so can cause damage to both the bolt and engine components alike.

Credit: www.youtube.com

Briggs And Stratton Torque Specs Chart Pdf

Briggs & Stratton torque specs chart PDFs provide reliable and accurate information on the torque specifications for each model of Briggs & Stratton engines. This information can come in handy when performing maintenance or repairs, as it indicates how much force is needed to secure components such as nuts, bolts, and screws. By having a quick reference guide at hand, users can ensure that their engine remains properly secured and functioning optimally.

5Hp Briggs And Stratton Torque Specs

The Briggs and Stratton 5HP engine is a highly reliable and powerful motor, with a peak torque of 10.1 ft-lbs at 3100 RPMs. This makes the 5HP an ideal choice for powering lawn mowers, pressure washers, log splitters, tillers and other yard equipment. Its durable design also allows it to run smoothly in all types of weather conditions making it one of the most dependable engines on the market today.

19 Hp Briggs And Stratton Torque Specs

The 19 HP Briggs and Stratton torque specs are as follows: peak torque of 42.7 ft-lbs at 2600 RPM, crankshaft taper size of 1 inch x 3 5/32 inches, two keyways for a 0.500 in width, and the flywheel nut is torqued to 80 ft-lbs. It is important to always use the correct torque specifications when working with any engine or motor to ensure its optimal performance.

Conclusion

The Briggs and Stratton 17.5 HP engine is a reliable, powerful option for many different types of machinery. With its maximum torque rating at 26 ft-lbs, this engine can handle the toughest jobs while keeping up with the demands of your workload. The specs make it easy to understand how the engine functions, so you can be sure that your machine will run smoothly and efficiently.

All in all, the Briggs and Stratton 17.5 HP Engine Torque Specs offer everything necessary to get any job done safely and effectively – making it an ideal choice for anyone looking for a dependable power source.