Ram 1500 Air Suspension Problems (2013-2025)

The Ram 1500’s Active-Level Four-Corner Air Suspension is a feature that, when new, provides a class-leading ride quality and exceptional utility. However, for many owners, this complex system has become a significant source of reliability concerns and expensive repairs.

These air suspension problems are a common occurrence, particularly in cold-weather climates, and are a frequent topic of discussion in automotive forums. The most common failures stem from air leaks in the rubber air springs, premature compressor burnout due to moisture intrusion, and a variety of electronic faults involving sensors and control modules.

This data-driven report provides an exhaustive analysis of the Ram 1500 air suspension system, diagnosing the key symptoms, identifying the root causes of failure, and detailing official Technical Service Bulletins (TSBs) issued by Ram. Furthermore, it presents a comprehensive breakdown of OEM repair costs versus the long-term solution of a coil spring conversion.

The Active-Level™ Four-Corner Air Suspension is an advanced system designed to provide a smoother and more controlled ride. Its primary marketed benefits include automatic load-leveling, which is ideal for towing, and five adjustable ride height settings:

- Normal Ride Height (NRH): The standard driving position.

- Aero Mode: Automatically lowers the truck at highway speeds to reduce drag and improve fuel efficiency.

- Off-Road 1 & 2: Lifts the truck for additional ground clearance.

- Entry/Exit Mode: Lowers the truck for easier ingress and egress.

While innovative, this system’s complexity is its greatest weakness. The combination of electronic sensors, an air compressor, a control module, a valve block, and rubber air springs creates numerous potential points of failure, which has led many owners to seek solutions for a system that becomes prohibitively expensive to maintain.

Ram 1500 Air Suspension

The Highs and Lows of a Premium Feature

The “Active-Level Four-Corner Air Suspension” is a standout feature for the Ram 1500, offering unparalleled ride comfort and adjustability. However, as these trucks age, owners are increasingly encountering a common set of problems. This infographic visualizes the data behind the most frequent failures, costs, and trends.

Common Failure Points

While the system is complex, the majority of problems are concentrated in a few key components. Air leaks are the most common culprit, followed by the compressor which can fail from being overworked due to those same leaks.

Key Takeaway: Over 40% of all reported issues are linked to leaking air springs. This often leads to the secondary failure of the compressor, which accounts for another 30% of problems.

Symptoms of Failure

How do you know if your air suspension is in trouble? The signs are usually obvious and should not be ignored. Acting quickly can prevent more expensive, cascading failures (like a leaking bag destroying a compressor).

“Service Air Suspension” Warning

The most direct indicator. This light on the dash means the onboard computer has detected a fault.

Truck is Sagging

The truck visibly droops at one corner, the entire front, or the entire rear, especially after being parked overnight.

Compressor Runs Constantly

You can hear the compressor (a whirring sound near the front) running non-stop as it tries to compensate for an air leak.

Problem Reports by Model Year

Analyzing owner complaints shows a clear trend. Problems were most prevalent in the initial model years of the 4th Generation (2013-2014) after the system’s introduction. Reports tapered off as the generation matured, but as with any air suspension, problems can arise on any model year as mileage and age increase.

Key Takeaway: The 2013 and 2014 models show the highest rate of complaints, typical for a new complex system. Newer models generally perform better, though long-term durability past 100,000 miles remains a common concern for all years.

Average Repair Costs

The cost of repairs is a major concern for owners. A single component can be expensive, and one failure often reveals others. Prices shown are estimates for parts and labor at a dealership or independent shop. A full system conversion to traditional coil springs is also an option many owners consider.

Key Takeaway: Replacing a single air spring can cost up to $700, but a compressor failure is often over $1,000. If the entire system needs replacement, costs can exceed $3,000, making it a significant financial consideration.

Simple Diagnostic Flow

If you suspect a problem, you can follow this simple diagnostic flow to help pinpoint the issue before heading to a mechanic. This process starts with the most obvious indicators and moves to a common at-home test.

1. Check for Warnings

Is the “Service Air Suspension” light on?

2. Visual Inspection

Is the truck sagging at any corner when parked?

3. Listen for Compressor

Does the compressor run excessively or not at all?

4. Perform Soap Test

Spray soapy water on air bags and lines. Look for bubbles, which indicate a leak.

Is Your Ram 1500 Air Suspension Failing? 7 Key Symptoms to Watch For

Diagnosing a failing air suspension begins with recognizing the tell-tale signs. These symptoms range from obvious dash warnings to subtle changes in ride quality.

1. “Service Air Suspension” Message

This is the most direct indicator. When the Air Suspension Control Module (ASCM) detects a fault in the system—be it a pressure loss, a sensor out of range, or a communication error—it will illuminate a warning message on the instrument panel cluster. Critically, this does not always mean a component is broken. As detailed in Technical Service Bulletin 08-152-24, this message can be triggered by a software bug that falsely reports ride height sensors as “stuck”.

2. Truck is Sagging or Leaning

This is the classic visual symptom of a significant air leak. Owners will often report the truck is “sitting on its bump stops,” particularly at one corner or across an entire axle. This indicates the air spring (or “air bag”) at that corner has a tear or the valve block is failing to hold pressure, causing the system to collapse once the vehicle is turned off.

3. Compressor is Noisy or Runs Constantly

The air compressor is the heart of the system, and it should run minimally and quietly. If you hear a loud, straining compressor, or if it runs for a long time after startup, or even cycles on and off while driving, it is a definitive symptom of a problem. This is not a compressor failure itself, but rather a symptom of a leak.

The system is experiencing a cause-and-effect failure cascade: a leak in an air spring causes low pressure; the height sensor signals the ASCM; the ASCM commands the compressor to run continuously to compensate for the lost air. This constant operation far exceeds its intended duty cycle, leading to overheating and eventual burnout.

4. Total System Malfunction in Cold Weather

This is perhaps the most infamous problem associated with the Ram 1500 air suspension. Owners consistently report the system working flawlessly during warmer months, only to have it fail completely when the temperature drops, often below 28°F. The truck will refuse to raise, displaying the “Service Air Suspension” message. This symptom points directly to the system’s core design flaw involving moisture intrusion, which will be detailed below.

5. Slow or Failed Ride Height Adjustment

When the system is healthy, adjustments between ride heights should be quick and smooth. A failing system will struggle to make these adjustments. The truck may adjust very slowly, or the system may fail to respond to the console button commands altogether. This can be caused by a large air leak, a weak compressor that can no longer build adequate pressure, or a fault in the control module.

6. Truck “Nosedives” on Braking

A properly functioning suspension supports the vehicle’s weight during dynamic shifts. If the front air springs are failing, they lose their ability to manage this weight transfer. As a result, the truck’s front end will dip excessively, or “nosedive,” when braking. This is a clear sign of suspension damage and poses a significant safety risk by increasing braking distance.

7. Stuck in Entry/Exit Mode

A specific issue, formally recognized by Ram in TSB 08-152-24, involves the truck getting “stuck” in its lowest height setting. An owner may lower the vehicle to load cargo, and then upon driving away, the system fails to raise the truck back to Normal Ride Height.

The 4 Main Causes of Ram Air Suspension Failure (And Why It Fails in Winter)

Understanding the symptoms is the first step. The next is understanding the technical root causes. Most failures are not isolated events but part of a chain reaction.

1. Air Leaks (The Most Common Culprit)

The vast majority of air suspension problems begin with a simple leak. The air springs, which are rubber bladders, are the primary point of failure. Over time and with mileage (a typical lifespan is 80,000 to 100,000 miles ), the rubber dries out, becomes brittle, and develops small cracks and tears from the constant flexing. Air lines, particularly in cold weather, can also become brittle and crack.

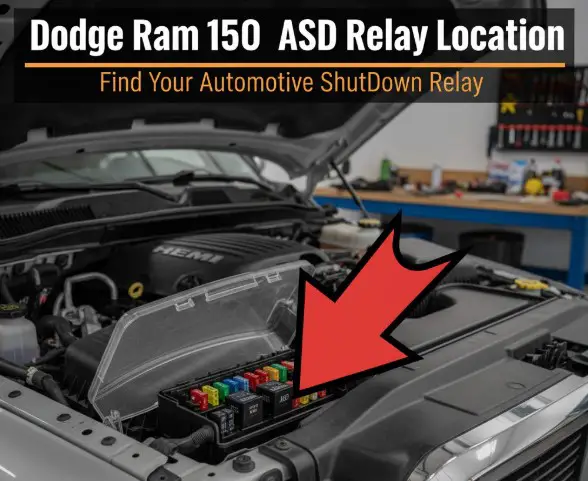

How to Find an Air Leak: The DIY Soapy Water Test

For owners suspecting a leak, a simple diagnostic can be performed at home.

- Mix a solution of mild dish soap and water in a spray bottle.

- Start the truck and ensure the suspension system is pressurized (at Normal Ride Height).

- Generously spray the solution onto all four air springs, the air lines, and the fittings at the compressor and valve block.

- Closely observe the sprayed areas. The escaping air from a leak will create visible bubbles in the soap solution, pinpointing the exact location of the failure.

2. Compressor Burnout (The Inevitable Result)

As established, a leaking system forces the compressor to run constantly, leading to overheating and failure. This is compounded by the system’s core design flaw, which is the root of the notorious cold-weather failures.

Here is a step-by-step analysis of this design paradox:

- Step 1: The Ram air suspension is designed as a “closed” system, ideally filled with pure, dry nitrogen from the factory.

- Step 2: However, the system is also designed with a “failsafe.” When a leak is detected and system pressure drops, the compressor is programmed to pull in ambient (outside) air to try and maintain the ride height.

- Step 3: This ambient air contains humidity (moisture). The compressor is equipped with a dryer unit to remove this moisture, but it is quickly overwhelmed and saturated by the constant influx of new, moist air from the leak.

- Step 4: In cold weather, this trapped moisture freezes. Ice forms within the system, blocking valves, cracking the (now brittle) air lines, and ultimately destroying the mechanical components of the compressor itself.

The system’s “solution” to a leak (pulling in outside air) is the very mechanism that introduces the contaminant (water) that guarantees its catastrophic failure in cold climates.

3. Electronic & Sensor Failures

The system is managed by a complex network of electronics, which are also common points of failure.

- Faulty Height Sensors: Each corner of the truck has a ride height sensor that tells the ASCM the vehicle’s position. These sensors are located in the wheel wells, where they are exposed to water, salt, and debris. They can fail, corrode, or send “oscillating” and implausible data to the module, causing erratic system behavior.

- Air Suspension Control Module (ASCM) Failure: The ASCM is the “brain”. While the module itself can fail, official TSBs from Ram prove that the module’s software is often the culprit. TSBs 08-152-24, 08-127-23, and 08-045-14 all list “ASCM software updates” as the fix for a range of issues, including false “Service Air Suspension” messages , “Battery Voltage Low” warnings, and stuck sensors.

4. The “Maintenance-Free” Myth

Ram has been criticized for marketing the air suspension as a “maintenance-free” system. This is demonstrably false and has created a “knowledge gap” for owners. In reality, to survive in cold climates, the system requires proactive maintenance that Ram does not publicize. Experienced owners and technicians recommend periodically draining the air tank’s water traps (if accessible) and even adding air brake antifreeze to the system before winter to prevent freezing. The lack of this documented procedure contributes directly to the high failure rate.

Model Year Reliability & Official Ram TSBs

While the air suspension has been an option for many years, the problems are not distributed equally.

4th Gen Ram 1500 (2013-2018): The Epicenter of Problems

The fourth-generation (DS/Classic) Ram 1500 is the model most associated with these failures. Complaints from owners of these model years are rampant, with failures commonly occurring after 50,000 to 80,000 miles. This mileage range aligns with the typical 80,000 to 100,000-mile expected lifespan of the rubber air springs themselves. Forum discussions are filled with owners who have spent over $5,000 on multiple repair attempts, only for the system to fail again the following winter.

5th Gen Ram 1500 (2019+): Are the Problems Fixed?

The evidence suggests the problems are not fixed in the fifth-generation (DT) platform. While the ride quality is praised, owners of 2019 and newer models continue to report the same failure patterns.

The most definitive proof is that Ram is still actively issuing software patches for the system. The existence of recent TSBs targeting 2022 and 2023 models confirms that the electronic and sensor issues are still present in the newest trucks.

Key Technical Service Bulletins (TSBs) You Must Know

A TSB is an internal document issued by a manufacturer to its dealers, outlining a fix for a known, non-safety-related problem. If your truck exhibits these exact symptoms, the repair may be a simple software update.

- TSB 08-152-24 (Issued June 2024):

- Applies to: 2022 – 2023 Ram 1500 (DT).

- Symptoms: “Service Air Suspension” message in the cluster; air suspension stuck in the lowered Entry/Exit mode after loading cargo.

- DTCs: C151E-2A (Left Front Ride Height Sensor – Stuck), C1522-2A (Right Front), C1526-2A (Left Rear), C152A-2A (Right Rear).

- Fix: Reprogram the Air Suspension Control Module (ASCM) with the latest software.

- TSB 08-045-14 (Issued May 2014):

- Applies to: 2013 – 2014 Ram 1500 (DS).

- Symptom: A false “Battery Voltage Low – Start Engine to Change Ride Height” message appears when locking or unlocking the doors.

- Cause: The ASCM fails to go to “sleep” mode, remaining awake and draining the battery.

- Fix: Update the ASCM software

The Financial Impact: The Shocking Cost of OEM Air Suspension Repair

The primary driver for seeking alternative solutions is the severe financial burden of repairing the factory system. Once out of warranty, owners are faced with repair estimates that can be staggering.

The following table synthesizes data from automotive repair cost estimators to provide a clear picture of what owners can expect to pay at a dealership for OEM parts and labor.

| Component | Estimated Part Cost | Estimated Labor Cost | Total Estimated Cost (Dealer) | Data Source(s) |

| Air Suspension Control Module (ASCM) | ~$1,195 | ~$98 – $143 | $1,293 – $1,338 | RepairPal |

| Air Compressor (Active Suspension) | ~$1,529 | ~$193 – $283 | $1,722 – $1,812 | RepairPal |

| Air Spring (Single, 2019-2023) | ~$881 | ~$122 – $179 | $1,003 – $1,060 | RepairPal |

| Rear Air Bag (Single, 2013-2017) | ~$2,000 – $3,000 | ~$300 – $500 | $2,370 – $3,500+ | YourMechanic |

A realistic failure scenario often involves a leak in one or more air springs that, in turn, burns out the compressor. Based on this data, replacing all four air springs and the compressor at a dealership could easily cost between $5,000 and $8,000, confirming the anecdotal reports of $5,000+ repair bills. These high costs are sourced from reputable automotive repair estimators like(https://repairpal.com/), which aggregate data from certified shops. These complex electronic repairs are one of many potential(https://truckguider.com/common-4th-gen-ram-1500-problems).

The Solutions: Repair vs. Convert (A Data-Driven Comparison)

Owners facing a failed system have two main paths: repair the OEM system (or a smarter aftermarket version) or permanently delete it with a coil spring conversion kit.

Solution 1: Repairing the System (The “Smarter” Way)

For those who choose to repair, using the same failure-prone OEM components is often a bad investment. A smarter solution exists in the “OE Fix” aftermarket.

Aftermarket manufacturers analyze why an original part fails and re-engineer it to be more robust. The Dorman 949-356 air compressor is a prime example.

- The Flaw: The original equipment (OEM) compressor features a plastic piston that melts and fails when the motor overworks from a leak.

- The Fix: The Dorman OE FIX version is upgraded with a durable aluminum piston and a motor rated for greater thermal capacity, allowing it to withstand higher temperatures for longer.

- The Cost: This superior part is also significantly cheaper, retailing for around $670 compared to the $1,700+ OEM part from a dealer.

Solution 2: The Permanent Fix (Coil Spring Conversion Kits)

For many owners, the most logical and popular long-term solution is to “delete” the air suspension entirely. This involves removing all four air springs and the compressor, replacing them with a passive system of traditional coil springs and shocks.

The “Warning Light” Problem

This conversion is not as simple as swapping parts. The Air Suspension Control Module (ASCM) is integrated into the truck’s computer. If the module no longer detects the sensors and compressor, it will trigger a permanent, non-stop “Service Air Suspension” warning light on the dashboard.

The Module Solution

Reputable conversion kits have solved this problem. They must include an electronic module that plugs into the factory harness to trick the ASCM into believing the air system is still present and healthy.

- Arnott calls its patented solution an Electronic Bypass Module (EBM).

- Strutmasters and other brands call it a “Light Fix Module”.

A kit without this module is an incomplete solution and should be avoided.

Top Conversion Kit Brands & Costs

Several major brands offer solutions that are often cheaper than replacing a single OEM air strut.

- Arnott: A premium brand known for its engineering, Arnott’s conversion kits typically cost between $1,060 and $1,450.48 They include the EBM to ensure no fault codes.

- Strutmasters: A popular conversion-focused brand. A kit for a 2019-2024 Ram 1500, which includes the “Light Fix Module,” costs approximately $1,579.

- Monroe: A highly-regarded and often more cost-effective option from a major OE supplier Full front-and-rear conversion kits can be found for around $575. One owner who installed a Monroe kit after repeated air failures praised it for restoring the factory ride height and delivering a smooth, reliable ride.

Comparison Matrix: Air Suspension vs. Coil Spring Conversion

The decision to repair or convert comes down to a clear set of trade-offs. The most critical factor is towing, as a coil conversion will lose the automatic load-leveling capability.

| Feature | Ram Active-Level Air | Coil Spring Conversion Kit |

| Long-Term Reliability | Poor. Prone to leaks & failure | Excellent. Maintenance-free |

| Total Cost | Extremely high to repair ($5,000+) | Low one-time cost ($575 – $1,600) |

| Ride Quality | Excellent, “smooth” | Good, restores factory height |

| Towing | PRO: Excellent (auto-leveling) | CON: Loses auto-leveling |

| Adjustability | 5 height settings | None (fixed height) |

Final Verdict: Should You Fix or Convert Your Ram’s Air Suspension?

The decision to repair or convert depends entirely on how the truck is used and the owner’s tolerance for future repair costs.

You should REPAIR the air suspension IF:

- You frequently tow or haul heavy loads. The automatic load-leveling feature is a “must-have” for this use case, and a coil conversion cannot replicate it.

- Your truck is still under warranty, in which case the repair should be covered by the dealer.

- Your problem is a known software bug that can be fixed with a simple and inexpensive TSB flash at the dealership.

You should CONVERT to coil springs IF:

- You do not tow or haul heavy loads, or only do so rarely.

- You live in a cold climate where the system is virtually guaranteed to fail repeatedly.

- Your truck is out of warranty, and you are facing a multi-thousand-dollar repair bill for a failed compressor or air spring.

- You value long-term reliability and the “set it and forget it” peace of mind that a passive coil system provides.

People Also Ask (In-Depth FAQ)

Q: Why does my Ram 1500 air suspension fail in cold weather?

A: The primary cause is moisture. The system is designed to pull in outside air when leaks are detected. This ambient air contains moisture that overwhelms the system’s dryer. In cold temperatures, this trapped moisture freezes. This ice blocks valves, cracks air lines, and ultimately destroys the compressor.

Q: How long should a Ram 1500 air suspension last?

A: The rubber air springs themselves have a typical wear lifespan of 80,000 to 100,000 miles. However, due to the moisture-related design flaw, compressors and other components often fail much earlier, especially in cold climates. Failures are widely reported in the 50,000 to 80,000-mile range.

Q: Can I drive my Ram 1500 with a failed air suspension?

A: It is strongly discouraged and unsafe. Driving with a collapsed suspension (riding on the “bump stops”) is a serious safety issue. It severely compromises handling, stability, and braking (causing “nosediving”) and can lead to catastrophic damage to other components.

Q: What is the cost to convert Ram air suspension to coil springs?

A: A complete, four-corner conversion kit (including all springs and shocks) typically costs between $575 for a basic, quality kit 51 and $1,600 for a premium kit that includes a warning light fix module. This one-time cost is often less than the price of replacing a single OEM air strut.

Q: How do I reset the Ram 1500 air suspension system?

A: A basic “soft” reset can be attempted by disconnecting the negative battery terminal for 10-15 minutes to clear the module’s temporary memory. A “recalibration” reset can sometimes be achieved by driving the vehicle above 25 mph for several minutes, allowing the system to self-adjust. However, if a hard fault or TSB-related code is active 11, it will require a dealer’s diagnostic scan tool to read and clear the specific codes from the ASCM.