Ram 2500 Transmission Problems (68RFE, Aisin, & Recalls)

The Ram 2500, particularly when equipped with the 6.7L Cummins engine, is a powerhouse of the heavy-duty truck market, designed for towing and hauling significant loads. This platform produces “monumental torque,” but for over a decade, its automatic transmissions “haven’t always kept pace”. This dissonance has made the transmission the Ram 2500’s most notorious “Achilles’ heel” and “weak link,” a common source of frustration and expensive repairs for owners.

This is not a single, isolated issue. The problems span across the different automatic transmissions offered by Ram, from the standard-duty 68RFE to the optional “heavy-duty” Aisin AS69RC. Both units possess significant, well-documented flaws.

This guide provides a comprehensive, data-driven analysis of Ram 2500 transmission problems. We will dissect the specific failure points of each transmission, identify the symptoms of a failing unit, analyze official NHTSA safety recalls and investigations, and provide a real-world cost breakdown for repairs and solutions.

These transmissions are bolted to the legendary 6.7L engine, which has its own set of common issues. Read our 6.7L Cummins problems and reliability guide.

Ram 2500 Transmission Problems: A Data Deep Dive

Visualizing the common issues, costs, and affected models.

Transmission Complaint Share

While several transmissions are used, owner complaints are not evenly distributed. The 68RFE transmission, common in Cummins-equipped trucks from 2007.5 to 2018, is the source of a vast majority of reported issues.

Typical Failure Mileage

A key concern for owners is *when* these problems surface. Data shows a significant spike in failures well outside the typical powertrain warranty period, commonly between 60,000 and 120,000 miles.

Reported Problems by Model Year (4th Gen)

Problem reports show a distinct trend, peaking with the 2014-2015 model years. This aligns with the mid-cycle of the 4th Generation Ram (2010-2018), where the 68RFE was the primary automatic transmission for the 6.7L Cummins engine.

Common 68RFE Failure Points

Dissecting the 68RFE issues reveals several core weaknesses. Overheating is a primary catalyst, leading to torque converter failure and solenoid pack issues. These components struggle to handle the high torque of the Cummins engine, especially when towing.

Average Repair Costs

The financial impact of these failures is significant. A full transmission rebuild is one of the most expensive repairs a truck owner can face, often costing upwards of $7,000. Even more minor-sounding repairs are costly.

Symptom to Diagnosis Flow

Recognizing the early warning signs is crucial. This diagram shows how common symptoms often trace back to specific underlying problems.

Shuddering or “Shuttle Shift” (hunting between gears)

Failing Solenoid Pack or Valve Body Issues

Slipping, Delayed Engagement, or High RPMs with No Power

Torque Converter Failure or Worn Clutch Packs

High Transmission Fluid Temps or “Limp Mode” When Towing

Inadequate Cooling or Fluid Breakdown

How to Protect Your Transmission

Prevention is far cheaper than repair. Proactive maintenance and smart upgrades are key to extending the life of a Ram 2500 transmission, especially the 68RFE.

Regular Fluid Changes

Stick to a 30,000-mile service interval with high-quality synthetic fluid. This is the single most important preventative step.

Install an Upgraded Cooler

An aftermarket transmission cooler is essential if you tow frequently. Keeping temperatures down is key to preserving clutches and fluid.

Upgrade Key Components

For high-mileage or tuned trucks, consider a heavy-duty torque converter and an improved valve body or solenoid pack *before* they fail.

Which Transmission is in My Ram 2500? (68RFE vs. Aisin vs. 66RFE)

Before diagnosing a problem, it is critical to identify which transmission is in the truck. The failure modes, symptoms, and repair costs are completely different for each unit.

- The 68RFE (Chrysler): This is the “standard” 6-speed automatic transmission paired with the 6.7L Cummins Standard Output engine. It was introduced with the 2007.5 model year and has been the most common automatic option since.

- The AS69RC (Aisin): This is the “heavy-duty” 6-speed automatic option, manufactured by Aisin Seiki. It was introduced in 2013 and is typically paired with the High-Output (HO) Cummins engines, which are designed for “intense applications”.

- The 66RFE (Chrysler): This 6-speed automatic is a common point of confusion. It was used in 2014-2018 Ram 2500 and 3500 trucks, but only with the gasoline 5.7L or 6.4L Hemi engines.7It is also known for being unreliable and part of an “outdated and inferior drivetrain technology”.

The very existence of the Aisin option is telling. Ram (a part of FCA/Stellantis) found it necessary to source a heavy-duty transmission from an outside, Toyota-affiliated company. This move was a tacit admission that their in-house 68RFE was not sufficient to reliably handle the “ferocity” of the Cummins engine under the high-torque, heavy-towing conditions for which the truck was advertised.

For a simple, real-world identification method, check the transmission fluid dipstick location.

How to Identify Your Ram 2500 Transmission

| Transmission | Engine | Model Years | Key Identifier(s) |

| 68RFE | 6.7L Cummins (Standard Output) | 2007.5 – Present | Transmission dipstick on the passenger side of the engine bay. |

| AS69RC | 6.7L Cummins (High Output) | 2013 – Present | Transmission dipstick on the driver’s side of the engine bay. |

| 66RFE | 5.7L or 6.4L Hemi V8 (Gas) | 2014 – 2018 | Paired with a gasoline engine. |

Deep Dive: The 68RFE Transmission (Problems & Failures)

The 68RFE’s problems are numerous and well-documented. The transmission is an evolution of earlier RFE units used in lighter-duty, gasoline-powered applications like the Dodge Dakota. As a result, it is often described by engineers as an “inflated gas transmission” that was “flawed from the factory”. It is simply not robust enough, in stock form, to handle the sustained, high-torque loads from the Cummins diesel engine.

The “Big 5” Symptoms of a Failing 68RFE

Owners of trucks with the 68RFE should be alert to these common symptoms, which often precede a catastrophic failure.

- Slipping Gears or Delayed Shifting: This is the most common complaint. The truck may hesitate, or the engine RPMs will “flare” (spike) between shifts without a corresponding increase in speed. This is especially noticeable when the transmission is shifting into 4th or 5th gear.

- Harsh or Erratic Shifts: Sudden, violent “bangs” or hard jolts when the transmission shifts, even under light throttle. This is a clear sign of erratic hydraulic pressure regulation.

- Overheating: Heat is the “#1 killer” of the 68RFE. If the transmission temperature gauge regularly pushes over 200°F, especially when towing or sitting in traffic, the transmission is in danger.

- Torque Converter Shudder: A low-speed vibration or shudder that feels like driving over rumble strips. This is a sign the torque converter is breaking down and struggling to lock up.

- Limp Mode / Stuck in Gear: This is a protective measure by the truck’s computer. When a severe slip or incorrect gear ratio is detected, the computer will trigger a Diagnostic Trouble Code (DTC) and lock the transmission in a single gear (often 3rd) to prevent further damage. The truck may also fail to engage Drive or Reverse, or suddenly drop into Neutral while driving.

Root Cause Analysis: Why the 68RFE Fails

The 68RFE’s failures are a predictable cascade. One failure point directly causes the next.

- Failure Point 1: The Valve Body: The transmission’s hydraulic “brain” is the root of most 68RFE evil. The stock valve body is “prone to wear”.2 The aluminum channels in the valve body wear out, allowing hydraulic fluid to “cross-leak”. This results in a loss of line pressure and erratic pressure regulation. This problem is often made worse by aftermarket performance tunes, which aggressively raise line pressure and can warp the stock accumulator plates, exacerbating the leaks.

- Failure Point 2: The Overdrive Clutch Pack: According to aftermarket parts manufacturer Sonnax, this is “the most common failure point”.8 The Overdrive clutches are simply too small for the application. Their lack of surface area means they cannot effectively dissipate heat. They “easily become warped,” which pushes the clutch clearances out of specification. The overdrive housing itself is also known to flex under pressure, further compromising the clutches.

- Failure Point 3: The Torque Converter: This is another “known failure point”. The stock torque converter “cannot withstand the torque” 9 of the Cummins engine. It breaks down, causing the shudder and contributing to the overheating problem.

These three points are interconnected. The failure does not happen at random; it is a direct chain of events.

- It begins when the valve body wears out.

- This wear causes hydraulic pressure to leak, which means the Overdrive clutches are no longer being applied with the required clamping force.

- Because the undersized clutches lack sufficient pressure, they begin to slip under the Cummins’ torque.

- This slipping generates massive heat—the transmission’s worst enemy.

- This extreme heat burns the transmission fluid , which loses its lubricating properties, and warps the clutch plates, causing even more slipping.

- This destructive cycle of slipping, heat, and burnt fluid quickly destroys the torque converter.

- The computer eventually detects the massive slip and throws the truck into limp mode, signaling a total failure.

This cascade explains why a simple “clutch” replacement is a temporary fix at best. A permanent solution must address the root cause: the flawed valve body.

Deep Dive: The Aisin AS69RC Transmission (Problems & Failures)

Many Ram 2500 owners paid a premium for the “heavy-duty” Aisin AS69RC transmission, believing it would be a “silver bullet” for the 68RFE’s problems. Unfortunately, this unit has its own, arguably more dangerous, set of issues, including critical manufacturing defects that can lead to sudden, catastrophic failure on brand-new trucks.

Common Aisin AS69RC Symptoms

While some symptoms are similar to the 68RFE, the Aisin has a unique and alarming failure mode.

- Overheating: Like the 68RFE, the Aisin can overheat, especially during heavy towing on steep inclines.

- Gear Hunting: Owners report the transmission seems confused, “hunting” for the correct gear and being unable to determine the correct shift point when hauling.

- Torque Converter Shudder: A shudder or vibration during torque converter lockup, pointing to a weak stock converter.

- Catastrophic, Sudden Loss of Gears: This is the most alarming symptom. Owners report a sudden, complete loss of forward motion, specifically losing gears 1 through 4, often with no warning.

Root Cause Analysis: Major Aisin Failure Points

- Failure Point 1: The K1 Clutch Snap Ring (A Critical Defect): This is the most significant problem with the modern Aisin. It is a “defective part”.18 The K1 clutch snap ring can dislodge from its groove in the clutch drum. When this happens, it causes an immediate “loss of torque transfer for lower gears 1, 2, 3 and 4”. This is not a gradual slip; it is a catastrophic failure that results in a “complete lost [sic] of motive power” , often at speeds above 25 mph.

- This specific defect is the subject of a 2024 NHTSA investigation targeting certain 2022 Ram 3500, 4500, and 5500 models, with a potential vehicle population of 188,320 trucks.

- This failure triggers DTC P0731-00 (Gear 1 Shift Incorrect Ratio).

- The official fix is TSB 21-002-23, which requires a complete, labor-intensive transmission teardown to replace the defective ring.

- Failure Point 2: The Torque Converter: The Aisin’s “heavy-duty” reputation is undermined by its torque converter. It uses a “3 steel/3 friction” lockup assembly that is “so small that the torque capacity is roughly the same as a 68RFE torque converter”. This inadequate design is the source of the common shuddering symptoms and leads to early wear when towing.

- Failure Point 3: Catastrophic Early Failures: The K1 snap ring defect is validated by horrifying owner complaints. One fleet owner of 2022 Ram 5500s reported that 6 out of 8 new trucks lost their transmissions with less than 7,000 miles. Some were on their third replacement transmission, indicating the replacement units were built with the same defect.

This data reveals a critical distinction between the two transmissions’ failure modes. The 68RFE and Aisin present a different “trade-off of risk.” The 68RFE’s problems are based on design flaws—it’s a “wear-and-tear” failure. It degrades over time and will often warn the owner it’s failing with slipping, shuddering, and overheating. This gives the owner time to plan and budget for the inevitable, expensive rebuild.

The Aisin’s K1 snap ring problem, by contrast, is a manufacturing defect. It causes a sudden, catastrophic failure with no warning, creating an immense safety hazard (losing all forward gears on a highway). The choice for a buyer is: purchase a truck with a transmission that will likely need a $7,000+ upgrade (68RFE), or one that is probably stronger but could catastrophically and unexpectedly fail at any moment (Aisin)?

Official Recalls & Safety Investigations (NHTSA Data)

Ram 2500 transmission problems are not just an inconvenience; they are the subject of multiple official recalls and safety investigations by the National Highway Traffic Safety Administration (NHTSA) for fire and roll-away risks.

Safety Recall 22V-835: FIRE RISK (2020-2023 68RFE)

This is a critical safety recall (NHTSA 22V-835 / Ram code ZA3) that affects approximately 248,800 trucks.

- The Problem: Heat and pressure can build up inside the 68RFE transmission. This pressure can “result in transmission fluid being expelled from the dipstick tube”.

- The Hazard: The expelled, flammable transmission fluid can spray onto hot ignition sources in the engine bay, “and cause a fire without warning”.

- Affected Vehicles: 2020-2023 Ram 2500 and 2020-2022 Ram 3500 pickups equipped with the 6.7L Cummins engine and the 68RFE transmission.

- The Remedy: Dealers will install a new, locking transmission dipstick and a new transmission vent tube, free of charge.

NHTSA Investigation: ROLL-AWAY RISK (2013-2018 Column Shifters)

NHTSA has launched a probe into an estimated 1.2 million Ram trucks (models 1500 through 5500) equipped with column shifters.

- The Problem: The investigation focuses on the Brake Transmission Shift Interlock (BTSI). The BTSI locking pin can get stuck in the open position. This allows the transmission to be shifted out of Park without the driver pressing the brake pedal or even having the key in theignition.

- The Hazard: This defect can lead to the truck rolling away unexpectedly. This investigation was opened after Ram’s previous recalls (17V-821 and 18V-100) for the same issue, as NHTSA received reports of seven injuries from trucks that had already had the recall “fix” performed.

NHTSA Investigation: K1 SNAP RING (2022 Aisin)

As detailed previously, the K1 snap ring failure is not just a TSB. It is an active NHTSA investigation due to the “complete lost [sic] of motive power at speeds above 25 mph”. The agency is evaluating this as a critical safety defect to determine if a formal recall is necessary.

Technical Service Bulletins (TSBs) to Know

A Technical Service Bulletin (TSB) is an instruction from Ram to its dealers on how to diagnose and fix a known, common problem. If your truck exhibits these symptoms, referencing the TSB number can save diagnostic time.

Key Ram 2500 Transmission TSBs

| TSB Number | Transmission | Models | Symptom(s) |

| TSB 21-012-25 Rev. B | 68RFE | 2024 Ram 2500/3500 | Malfunction Indicator Lamp (MIL), limp mode, multiple DTCs (P0729, P0868, etc.). Cause: Rear selective thrust bearing cracking. |

| TSB 21-002-23 Rev. B | Aisin AS69RC | 2019-2023 (see TSB) | DTC P0731-00, loss of gears 1-4. Cause: K1 clutch snap ring dislodged. |

| TSB 21-019-22 | Aisin AS69RC | 2021 Ram 3500-5500 | Harsh shifts, poor shift quality (especially at light pedal). Cause: TCM software logic needs update. |

| TSB 18-027-16 Rev. C | 68RFE | (2016-era) | Provides “Overall Shift Quality Improvements,” and software fixes for DTCs P0218 (High Temp) and P0868 (Line Pressure Low). |

68RFE vs. Aisin AS69RC: Which is Actually Better?

One of the most common questions from prospective buyers is whether to get the 68RFE or pay for the Aisin upgrade.25 The data shows this is a complex trade-off, as both units have significant flaws. The “better” transmission depends on the owner’s budget and tolerance for risk.

68RFE vs. Aisin AS69RC: A Head-to-Head Comparison

| Characteristic | 68RFE | Aisin AS69RC |

| Design | “Inflated gas transmission”. | “Heavier-duty” design, derivative of Toyota Land Cruiser transmissions. |

| Stock Reliability | Poor. Prone to gradual wear-and-tear failure from the valve body and clutches. | Good, BUT… Prone to sudden manufacturing defects (K1 snap ring) that cause catastrophic failure. |

| Stock Shift Quality | Can be a smooth-shifting transmission, though prone to slips. | Poor. “Shifts terribly,” “sludgy, unresponsive, and slow-to-shift”. |

| Aftermarket Support | Excellent. “Radical amount of aftermarket support”. | Poor. “Lacking in technical information” and has far fewer aftermarket parts. |

| Typical Failure | Gradual degradation (slipping, overheating). | Sudden, catastrophic defect (total loss of gears 1-4). |

| Repair Cost | Cheaper to build, with many options. | “Exceptionally difficult” and very expensive to find a qualified tech and parts. |

This data leads to a clear conclusion: The 68RFE is a fixer-upper. It is flawed from the factory and will likely fail if used for heavy towing, requiring a $7,000+ “built” transmission to become the reliable unit it should have been. Its greatest strength is its “radical” aftermarket support.

The Aisin AS69RC is a gamble. It is a heavier-duty transmission, but it “shifts terribly” and, more importantly, is subject to catastrophic manufacturing defects like the K1 snap ring. It is also “exceptionally difficult” and expensive to repair, with a poor aftermarket.

Cost to Fix Ram 2500 Transmission Problems (2025 Data)

Understanding the problems is one thing; budgeting for the fix is another. The costs are high and vary significantly between a simple “rebuild” and a necessary “built” upgrade.

68RFE Rebuild vs. Replacement vs. “Built” Cost

This is the most critical financial insight for a 68RFE owner: a standard “rebuild” is not a “fix.” A basic rebuild ($3,000-$5,000) simply replaces the worn-out factory parts with new, identical factory parts—which are the same flawed components that failed in the first place. This is a “temporary fix, not for towing/power”.

A true, long-term solution requires a “built” transmission. This process involves upgrading the weak points (valve body, clutch packs, torque converter) with heavy-duty aftermarket components. This is the necessary cost to correct the 68RFE’s factory flaws and make it reliable for towing.

68RFE Transmission Cost Comparison (2025 Data)

| Option | 2025 Estimated Cost | Strength / Best For |

| Basic Rebuild | $3,000 – $5,000 | Stock-level. A “temporary fix, not for towing/power”. |

| OEM Replacement | $5,000 – $6,500 | OEM strength only. For stock trucks, short-term use. |

| “Built” Transmission | $5,400 – $13,000+ | Stronger than OEM. The required fix for towing, tuned, or high-horsepower trucks. |

Aisin AS69RC Repair Costs

Repairing the Aisin is a more specialized and expensive affair. The aftermarket is smaller, and parts are pricier.

- Parts: Basic rebuild kits (clutches and seals) alone run from $1,300 to $2,100. A new billet torque converter to fix the shudder costs around $2,000.

- Built Transmissions: A complete “built” Stage 1 Aisin transmission (which includes upgrades to prevent a K1 failure) starts around $8,800. High-performance builds easily exceed $10,000.

- Remanufactured Units: A remanufactured Aisin often requires a massive core deposit (e.g., $2,000) on top of the purchase price, which can be difficult for owners to get back if their original transmission has case damage.

How to Prevent Transmission Failure: A Maintenance Guide

While many of these failures are due to design flaws, a strict, proactive maintenance regimen is the only way to delay them and extend the transmission’s life.

1. Fluid: Your Transmission’s Lifeblood

- Check it: Check the transmission fluid regularly. Healthy fluid is bright red, clear, and smells sweet. If the fluid is dark, murky, or smells burnt/fishy, it is a sign of overheating and clutch material circulating in the system.

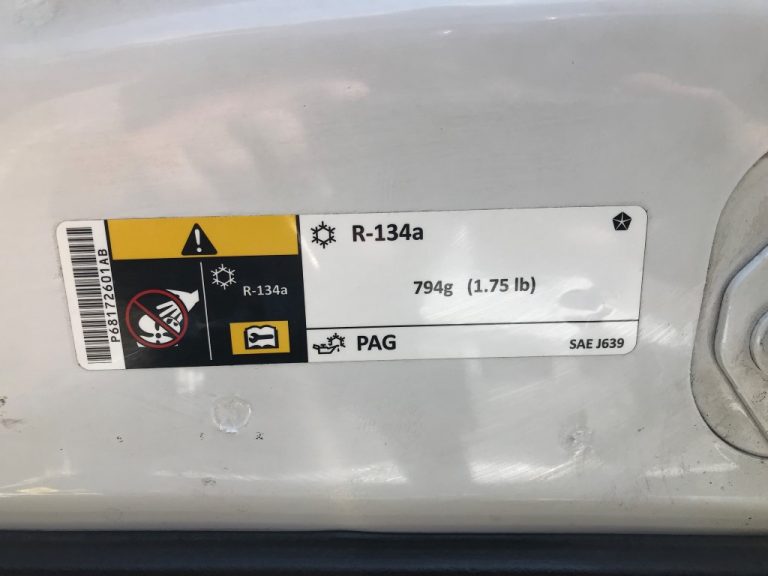

- Use the Right Type: This is non-negotiable. For the 68RFE, you must use Mopar ATF+4 or a licensed fluid that meets the MS-9602 specification. Using the wrong fluid can accelerate wear.

2. Service Intervals: Do NOT Trust the Manual

This is a critical trap for new owners. The owner’s manual may suggest a service interval as high as 120,000 miles. Following this advice is a recipe for failure. The engineering and repair data clearly show the fluid breaks down from heat far sooner. The expert consensus, and the “severe duty” schedule, is to change the transmission fluid and filter every 30,000 miles if you tow, and no later than 60,000 miles for normal use.

3. Manage Heat: The #1 Killer

As established, heat is the “#1 killer” of these transmissions. The stock transmission cooler is often insufficient for heavy loads. The two best preventative upgrades are an aftermarket deep-sump transmission pan and a larger, more efficient transmission cooler.32 A deep pan holds more fluid (which takes longer to heat up) and often has cooling fins to dissipate heat.

Regular fluid changes are critical, but managing heat with a deep transmission pan and cooler is the best preventative upgrade you can make.

4. Smart Driving Habits

- Let the truck warm up for a few minutes before driving, especially in cold weather, to allow the fluid to circulate.

- Come to a complete stop before shifting from Drive to Reverse (or vice-versa). Shifting while the truck is still rolling puts immense strain on the geartrain.

- When towing, maintain reasonable speeds and avoid “jack-rabbit” starts or abrupt acceleration, which shock-loads the transmission.

5. Keep Your Software Updated

Many shift quality issues are electronic, not mechanical. Manufacturers release software updates (flashes) for the Transmission Control Module (TCM) to improve shift logic. TSBs like 21-019-22 (Aisin) and 18-027-16 (68RFE) are purely software fixes to improve shift quality.

Ram 2500 Lawsuits: What About Legal Action?

With so many widespread problems, many owners ask about class-action lawsuits. While there is a clear pattern of defects, the most prominent current lawsuits for these trucks do not target these specific transmission failures.

- Emissions Lawsuit: A major class-action lawsuit filed against FCA alleges that 2019-2023 Ram 2500 and 3500 Cummins trucks were sold with defective emissions controls that “release illegally high levels of NOx emissions”.

- ABS Lawsuit: Another class-action lawsuit targets 2017-2018 Ram 2500 and 3500 trucks for allegedly “defective anti-lock braking systems” and hydraulic control units.

The absence of a major lawsuit for the 68RFE’s well-known wear-and-tear failures (after 15+ years) is notable. However, the NHTSA investigation into the 2022 Aisin K1 snap ring is a very recent development and is often the first step that provides the legal and technical foundation for a future class-action lawsuit.

Conclusion: What This Means for Ram 2500 Owners

The transmission problems on Ram 2500 heavy-duty trucks are not anecdotal; they are real, well-documented, and backed by engineering analysis, government recalls, and federal safety investigations.

The issues affect both primary transmission options.

- The “standard” 68RFE is “flawed from the factory” with an undersized clutch pack and a weak valve body that leads to a predictable cascade of wear, slipping, and overheating.

- The “heavy-duty” Aisin AS69RC is not a flawless solution. It offers a stronger build but is plagued by “terrible” shift quality and, more alarming, critical manufacturing defects like the K1 snap ring failure, which can cause a catastrophic and dangerous loss of power.

For a current or prospective owner, this data leads to a clear conclusion. Owning a Ram 2500 for heavy-duty work requires two things:

- Proactive maintenance that is more frequent than the owner’s manual suggests (30,000-60,000-mile fluid changes).

- Budgeting for an eventual, and likely necessary, transmission upgrade. A “built” 68RFE or a fortified Aisin is a $7,000 to $10,000+ investment, but it is often the only way to achieve the long-term reliability the truck should have had from the factory.

Frequently Asked Questions (FAQs)

Q: What are the most common signs of a Ram 2500 transmission failing?

A: The most common signs are gear slipping (RPMs flare between shifts), harsh or banging shifts, a shudder or vibration at low speeds (torque converter), and overheating (temps over 200°F). You may also experience “limp mode,” where the truck gets stuck in one gear.

Q: Is the 68RFE or the Aisin transmission more reliable in a Ram 2500?

A: Neither is perfect. The 68RFE is known to be unreliable in stock form and will likely need an expensive “built” upgrade. The Aisin is stronger but suffers from terrible shift quality and is prone to sudden, catastrophic manufacturing defects like the K1 snap ring failure.

Q: How much does it cost to replace a 68RFE transmission?

A: A standard rebuild is $3,000-$5,000 but is considered a temporary fix. A “built” transmission, which is recommended for towing, costs between $6,500 and $13,000+.

Q: Is there a recall on Ram 2500 transmissions?

A: Yes. Safety Recall 22V-835 (Ram code ZA3) was issued for 2020-2023 Ram 2500/3500 trucks with the 68RFE. Heat and pressure can expel fluid from the dipstick, creating a fire risk. There is also an NHTSA investigation into 2013-2018 models for a roll-away risk.

Q: What is the K1 snap ring failure on the 2022 Ram Aisin transmission?

A: This is a critical defect where a snap ring in the K1 clutch drum dislodges, causing a total loss of gears 1 through 4, often at highway speeds. This is the subject of NHTSA investigation 17 and TSB 21-002-23.

Q: How can I make my 68RFE transmission last longer?

A: 1. Manage heat: Install a deep-sump pan and larger cooler. 2. Change your fluid (ATF+4) and filter every 30,000-60,000 miles. 3. Update your TCM software. 4. Let the truck warm up and always stop completely before shifting from Drive to Reverse.