12 Valve Cummins Crank Position Sensor Location: Quick and Easy Guide

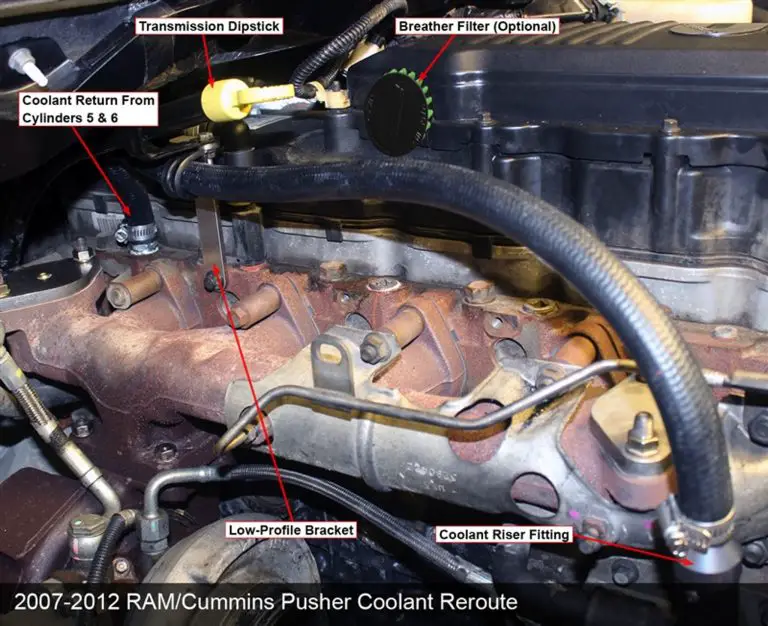

The crank position sensor on a 12 Valve Cummins engine is located on the damper pulley of the engine balancer. It can be found above the harmonic balancer, reading off of the engine damper, and is mounted by the harmonic balancer.

This sensor includes only the sensor and lead wire. The location and function of the crank position sensor is crucial in providing accurate data to the engine’s control module, helping to determine the exact position of the crankshaft and ensuring proper engine performance.

The Importance Of The Crank Position Sensor

The crank position sensor is a crucial component in a 12 Valve Cummins engine as it plays a vital role in measuring the engine’s RPM and position. By providing important data to the engine control unit (ECU), it helps ensure smooth engine operation. The sensor is typically located above the harmonic balancer, reading off the engine damper. It is responsible for detecting the rotational speed and position of the crankshaft, allowing the ECU to accurately control fuel injection and ignition timing. Without a properly functioning crank position sensor, the engine may experience issues such as hard starting, stalling, rough running, and poor fuel economy. The sensor is mounted by the harmonic balancer, and it includes the sensor itself and the lead wire. Regular maintenance and timely replacement of a faulty crank position sensor are essential for optimal engine performance.

Credit: www.jackphelandodgeonline.com

Locating The Crank Position Sensor In A 12 Valve Cummins

The crank position sensor in a 12 Valve Cummins engine is located above the harmonic balancer, reading off of the engine damper. It is attached to the back of the timing gear cover housing, below the fuel injection pump. To locate the crank position sensor, follow these steps:

To make the process easier and more efficient, consider the following tips and tricks:

By following these steps and utilizing the tips and tricks, you’ll be able to quickly and effectively locate the crank position sensor in your 12 Valve Cummins engine. |

Common Issues With The Crank Position Sensor

- Discussion of common symptoms that indicate a faulty crank position sensor.

- Exploring how a bad crank position sensor can affect the engine’s performance.

- Highlighting the importance of timely diagnosis and replacement of a faulty sensor.

A faulty crank position sensor can cause various issues with the engine’s performance. Common symptoms include Check Engine Light illumination, hard starting and/or stalling, engine runs rough or misfires, and poor fuel economy. It is essential to diagnose and replace a faulty sensor promptly to prevent further damage to the engine.

The crank position sensor is located above the harmonic balancer, reading off of the engine damper. It is responsible for detecting the position and speed of the crankshaft, providing critical information to the engine control module. If the sensor is not functioning correctly, it can lead to inaccurate ignition timing and fuel injection, resulting in performance issues.

Timely replacement of the faulty crank position sensor is crucial to maintain the engine’s optimal performance and prevent potential breakdowns. If you experience any of the common symptoms mentioned, it is recommended to consult a professional mechanic for diagnosis and replacement.

How To Replace The Crank Position Sensor

| Heading: How to Replace the Crank Position Sensor |

| Subheading: Detailed guide on properly replacing the crank position sensor in a 12 Valve Cummins engine |

| Necessary tools and equipment for the replacement process: |

|

| Step-by-step instructions and precautions to ensure successful sensor replacement: |

|

1. Locate the crank position sensor, which is typically located near the harmonic balancer of the engine damper. 2. Begin by disconnecting the battery to ensure safety during the replacement process. 3. Remove any necessary components that obstruct access to the sensor, such as belts or pulleys. 4. Disconnect the electrical connector from the sensor by carefully releasing the locking tab. 5. Gently remove the sensor from its mounting location, being cautious not to damage any surrounding components. 6. Install the new crank position sensor in the same location, ensuring proper alignment. 7. Reconnect the electrical connector and secure it with the locking tab. 8. Carefully reinstall any components that were removed during the process, such as belts or pulleys. 9. Finally, reconnect the battery and test the newly replaced crank position sensor. |

Crank Sensor Troubleshooting Tips

Understanding the possible causes behind sensor malfunctions and knowing how to test and diagnose problems with the crank position sensor are important for troubleshooting common issues. The crank position sensor is located on the damper pulley of the engine balancer. It is attached to the back of the timing gear cover housing, just below the fuel injection pump. The sensor mounts by the harmonic balancer and includes only the sensor and lead wire.

Some symptoms of a bad crankshaft position sensor include check engine light illumination, hard starting and/or stalling, engine running rough or misfiring, and poor fuel economy. To diagnose a faulty sensor, you can use a scan tool to check for any error codes related to the crank position sensor. Another test involves checking the sensor’s resistance using a multimeter.

If you are experiencing sensor issues, it is also important to check for any loose grounds or wiring issues. Additionally, be aware of the recommended gap for the crank sensor. If necessary, you can replace the sensor or bypass it if needed.

Expert Tips For Maintaining The Crank Position Sensor

|

Expert Tips for Maintaining the Crank Position Sensor Practical tips on ensuring the longevity and optimal performance of the crank position sensor

The crank position sensor is a crucial component in the 12 Valve Cummins engine. To ensure its proper functioning and avoid sensor failures, it is essential to follow some recommended maintenance practices. Regular inspections of the sensor and cleaning any dirt or debris accumulated on it are vital. Inspect and clean the sensor at least once a year or more frequently if you operate your vehicle in dusty or dirty conditions. During inspections, check for any signs of damage or wear such as cracks or frayed wires. If any issues are detected, it is advisable to replace the sensor. Additionally, make sure the sensor is properly connected and securely fastened in its location. Check for loose connections and tighten any fasteners as necessary. |

Frequently Asked Questions For 12 Valve Cummins Crank Position Sensor Location

Where Is The Crank Position Sensor On A 5.9 Cummins?

The crank position sensor on a 5. 9 Cummins is located above the harmonic balancer, reading off of the engine damper. It is attached to the back of the timing gear cover housing, below the fuel injection pump. It mounts by the harmonic balancer and includes only the sensor and lead wire.

Does A 12 Valve Cummins Have A Throttle Position Sensor?

Yes, a 12 valve Cummins engine does have a throttle position sensor located below the fuel injection pump. It is attached to the back of the timing gear cover housing.

Where Is The Exact Location Of The Crankshaft Position Sensor?

The crankshaft position sensor is located above the harmonic balancer, reading off of the engine damper. It is mounted by the harmonic balancer and includes only the sensor and lead wire.

How Can You Tell If Your Crankshaft Position Sensor Is Bad?

The symptoms of a bad crankshaft position sensor include check engine light illumination, hard starting and/or stalling, engine runs rough or misfires, and poor fuel economy. To determine if the sensor is bad, these symptoms should be checked. The sensor is usually located near the harmonic balancer or the timing gear cover housing.

Conclusion

The crank position sensor is a vital component of a 12 Valve Cummins engine. Located on the damper pulley or harmonic balancer, it plays a crucial role in determining the position and speed of the crankshaft. By providing accurate data to the engine control module, it ensures proper ignition timing and fuel delivery.

Understanding the location of this sensor is essential for troubleshooting and maintenance purposes. By following the guidelines provided in this blog post, you can easily locate and replace the crank position sensor on your 12 Valve Cummins engine.