12.7 60 Series Detroit Head Bolt Torque Specs

The 12.7 liter 60 Series Detroit Diesel engine head bolt torque specifications are as follows: The main bearing cap bolts should be tightened in three stages, beginning with a “snug” torque of 90 lb-ft (122 Nm) then progressing to a second stage of 110 lb-ft (149 Nm), and finally to the desired final torque spec of 120 lb-ft (163Nm). The connecting rod nuts should be torqued to 70 lb-ft (95 Nm). All other remaining head bolts should be tightened initially to 40 lb- ft (54 Nm) and then an additional 90 degree turn.

It is important to ensure that all fasteners are properly lubricated with oil or anti seize compound before installation and tightening.

When working on your Detroit Series 60 engine, it’s important to use the correct head bolt torque specs. The 12.7 liter 60 Series Detroit engines have a head bolt torque specification of 175 lb-ft for all bolts, with an additional 90 degrees of rotation for the final tightening. Following these specs is critical in order to ensure proper engine performance and reliability.

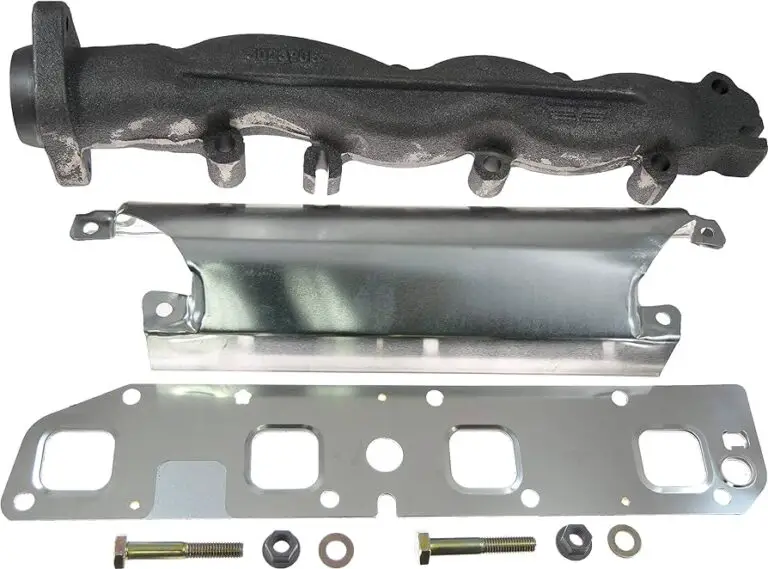

Shortened 60 Series Cylinder head install

What is the Torque on the Bolts on a Detroit Series 60 Water Pump?

The torque on the bolts of a Detroit Series 60 water pump is dependent on the size and type of bolt being used. Generally, for the standard 5/8 inch hex bolts, it is recommended that torque be set to 75-80 foot pounds (ft-lbs). For larger diameter fasteners such as 3/4 inch hex head or special shoulder bolts, it is best to use a higher torque setting of 85-90 ft-lbs.

To ensure proper installation and seal integrity, it is also important to evenly distribute and apply even pressure when tightening each bolt with a calibrated wrench. Additionally, all threads should be lubricated prior to assembly in order to avoid galling or seizing during operation. It’s also important not only to check the torque on all the bolts but also inspect them periodically for any signs of leakage or wear which could lead to premature failure and costly repairs down the road.

How Much Torque Does a 12.7 Detroit Have?

The 12.7 Detroit diesel engine has a peak torque rating of up to 1,650 ft-lbs (2,232 Nm) depending on the model and application. This is more than enough for most medium duty applications such as trucks, buses, construction equipment and agricultural machinery. The 12.7 Detroit also offers good fuel economy thanks to its advanced design features like the high pressure common rail injection system and turbocharging with variable geometry turbine (VGT).

In addition to offering great performance at low RPMs for greater fuel efficiency over longer distances, the 12.7 Detroit delivers strong torque even when operating under heavy loads or in extreme conditions due to its robust design components including an air-to-air aftercooler which helps manage temperatures during operation. Whether it’s used in a recreational vehicle or commercial trucking fleet, the 12.7 Detroit is sure to provide reliable power while meeting all your needs with plenty of torque available whenever you need it!

What is the Torque for Head Bolts?

The torque for head bolts is the amount of force needed to tighten them properly. It is important to ensure that the right amount of torque is used when installing head bolts. Too little and they might not be tight enough, too much and they can strip out or break off completely.

The proper torque for a given application depends on factors such as bolt diameter, thread pitch, application type (dry or lubricated) and material grade of the bolt being used. Generally speaking, standard grade bolts require between 65-90 ft/lbs while high-grade alloy steel bolts require greater values up to 200 ft/lbs depending upon application requirements. Always check your vehicle’s manual before attempting any repairs as incorrect torquing can cause serious damage or even engine failure if done incorrectly!

What is the Difference between Detroit 12.7 And 14L?

The Detroit 12.7 and 14L engines are two of the most popular diesel powerplants used in heavy-duty vehicles today. Despite their similar sizes, they have distinct differences that make them suitable for different applications and needs. The main difference between these two engines is their displacement, or the size of the cylinder block.

The Detroit 12.7 has a total displacement of 12.7 liters, while the 14L has a slightly larger capacity at 14 liters. Other than this key distinction, there are also other minor variations that help to differentiate one engine from another such as horsepower ratings, torque output levels and fuel efficiency ratings.

Credit: www.youtube.com

Detroit 60 Series Head Bolt Torque Specs

When replacing or re-assembling a Detroit 60 Series engine, it’s important to use the correct torque specifications for the head bolts. Generally, they should be tightened in three stages: first to 30 foot-pounds, then 90 foot-pounds and finally 150 foot-pounds. Be sure to check your manufacturer’s specifications before beginning any work on your engine.

Detroit 60 Series Camshaft Cap Bolt Torque

When replacing your Detroit 60 Series camshaft cap bolt, it is important to ensure that the bolts are torqued to the correct specifications. The proper torque for the camshaft cap bolts is 40-45 lb-ft when using a 6 point socket and 50-55 lb-ft when using a 12 point socket. It’s best to use an impact wrench if possible, as this will help ensure accuracy and consistency during installation.

Additionally, make sure you replace any worn out or damaged components before reassembling engine components.

Detroit 60 Series Flywheel Bolt Torque Specs

The flywheel bolt torque specs for the Detroit 60 Series engine are as follows: first, tighten each of the bolts to a snug fit in sequence (in a star pattern) and then bring them up to 65-70 ft.lbs of torque. Be sure to use an inch-pound torque wrench when tightening these bolts and always refer to the manufacturer’s instructions for specific guidelines.

Conclusion

In conclusion, the 12.7 60 Series Detroit Head Bolt Torque Specs is a must-know for anyone working on or repairing this engine model. Knowing the specific torque specs can help ensure that all components are tightened to the proper level and will allow your engine to run more efficiently with less wear and tear. By following these specifications, you’ll be able to keep your vehicle in peak condition for many years of reliable service.