5.7 Hemi Oil Pressure Sensor: The Complete Location & Replacement Guide (2025)

An erratic oil pressure gauge is a source of immediate panic for any 5.7 Hemi owner. Whether your gauge has suddenly bottomed out at zero, is flickering, or—most confusingly—is maxed out at 96 PSI even when the engine is off, the fear of a catastrophic engine failure is real. This is often accompanied by a check engine light, illuminating your dashboard with a Diagnostic Trouble Code (DTC) like P0520, P0523, or P0524.

Before you diagnose a failing oil pump (a complex and expensive mechanical repair), there is good news. In the vast majority of cases, these symptoms are not mechanical. They point to a much simpler and cheaper component: a failed oil pressure sensor, also known as a sending unit or switch.

The primary source of confusion for this repair is the “5.7 Hemi oil pressure sensor location” itself. A search provides conflicting answers because the location is not the same on all Hemi-equipped vehicles. The sensor is in an easy-to-access spot on a Ram 1500 or Jeep Grand Cherokee but is notoriously difficult to replace on a Dodge Charger, 300, or Magnum.

This failure is so common that Chrysler (now Stellantis) issued an official Technical Service Bulletin (TSB) recommending the replacement of the original sensor with a revised part.

This definitive guide will use technical data and diagrams to show you the exact location for your specific vehicle, detail the symptoms of a failed sensor versus a bad oil pump, provide the official Mopar part numbers, and give step-by-step replacement guides for both the “easy” (truck) and “difficult” (car) platforms.

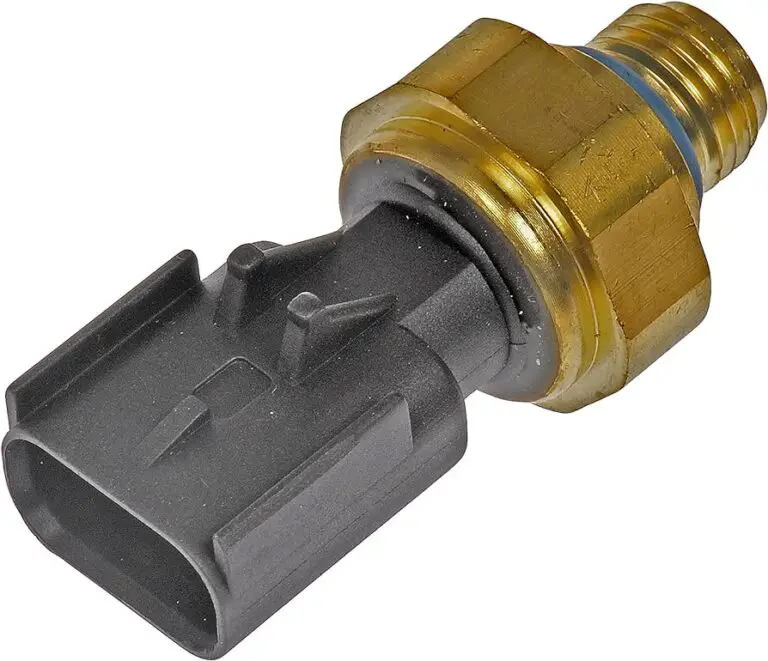

The 5.7 Hemi Oil Pressure Sensor

A Visual Guide to Location, Symptoms & Data

What It Is & Why It Matters

The 5.7 Hemi oil pressure sensor is a small but critical component in your engine. Its sole job is to monitor the oil pressure within the engine’s lubrication system. This system is the lifeblood of your motor, ensuring every moving part is properly lubricated to prevent catastrophic friction and heat.

The sensor translates this physical pressure into an electrical signal, providing the real-time data your truck needs to operate safely. When this sensor fails, your engine’s main line of defense is blind.

Information Flow

The sensor feeds vital data to two places:

Symptoms of a Failing Sensor

A bad sensor can mimic the scariest engine problems, like a failed oil pump. Before you panic, look for these specific symptoms. The most common issue is a faulty reading, not a lack of pressure.

Erratic Gauge

The oil pressure gauge on your dash swings wildly, drops to zero, or maxes out for no reason.

Flickering Oil Light

The red oil warning light flickers, especially at idle, even when the oil level is perfectly fine.

Check Engine Code

A “P0520” error code (or related codes P0521-P0524) appears when you scan the ECU.

Finding the Sensor: The Two Main Locations

This is the most common question. Chrysler has used two primary locations depending on your vehicle’s model and year. You’ll need to check both spots. A flashlight is essential.

Location 1: Near Oil Filter Housing

Common on many Ram 1500s. Look on the side of the engine block, just above the oil filter.

Location 2: Top-Rear of Engine

Common on many Jeeps & Chargers. Look at the back of the engine, below the intake manifold.

Replacement Process

This is a common DIY job. While steps vary by location, the general process is straightforward.

Data Deep Dive: Pressure & Costs

Understanding the data behind the sensor helps you diagnose problems and budget for repairs. Here’s what’s normal and what you can expect to pay.

Normal Operating Pressure (PSI)

Typical ranges for a healthy 5.7 Hemi. Pressure naturally increases with engine RPM.

Average Replacement Cost

Labor is often the biggest factor, especially if the sensor is in a hard-to-reach spot.

Key Warning: Can You Drive With a Bad Sensor?

It is **strongly advised not to drive** if you suspect a bad oil pressure sensor.

The problem is simple: you can’t be 100% sure if the sensor is bad or if your oil pump *actually* failed. If the sensor is lying, you’re fine. If the sensor is telling the truth and your pressure is zero, you will destroy your engine in minutes. It’s a gamble that can cost you over $10,000.

Always treat a zero-pressure reading or an oil light as a critical, “stop-the-engine-now” emergency until you can prove it’s just the sensor.

5.7 Hemi Oil Pressure Sensor Location: A Tale of Two Platforms

The confusion around the sensor’s location stems from the 5.7 Hemi’s use in two fundamentally different chassis types. The engine itself is the same, but the packaging—how accessories, the intake, and wiring are arranged around it—dictates the sensor’s location and, critically, its replacement difficulty.

- Platform 1: Trucks & SUVs (Ram, Jeep, Durango): The engine bay is large and open, providing ample room for service.

- Platform 2: Cars (Charger, 300, Challenger, Magnum): The same engine is packed tightly into the “LX” car platform, burying components that are easy to reach on a truck.

Location 1 (Easy): Ram 1500, Jeep Grand Cherokee, & Durango

On 5.7 Hemi-equipped trucks and SUVs, the oil pressure sensor is located in an accessible position on the front of the engine block, on the driver’s side.

To find it, look down past the serpentine belt and engine accessories. The sensor is typically threaded directly into the oil filter housing or the engine block right next to it. Official Mopar part diagrams confirm this, describing the location as “At Oil Filter Adaptor”.

- Ram 1500 (2002-2008): The location is consistent on 3rd Generation Ram 1500s

- Ram 1500 (2012-2014): The sensor remains on the front driver’s side, accessible from the top of the engine bay.

- Jeep Grand Cherokee (2005-2010): The sensor is accessible, though on some models, it may be tucked near the transmission cooler lines. Repair guides for 2006-2007 5.7L models provide clear diagrams of this location.

- Jeep Grand Cherokee (2011-2016): The location is similar to previous generations, remaining at the front of the engine.

Location 2 (Difficult): Dodge Charger, 300, Challenger, & Magnum

On the 5.7 Hemi “car” platforms, the sensor is not at the front. It is located in a deep, inaccessible spot: in the engine valley, on top of the block, but buried under the intake manifold.

You cannot see this sensor from the top or sides of the engine without significant disassembly. To reach it, a technician must remove the entire upper accessory drive, including the air intake boot, the serpentine belt, the alternator, and often the EGR valve, just to gain clear access. This intensive labor is what turns a 30-minute job into a 3-hour job

Bad 5.7 Hemi Oil Pressure Sensor Symptoms (And What They Mean)

The symptoms of a failed sensor are almost always electrical, not mechanical. This distinction is crucial for a correct diagnosis.

Key Telltale Sign: Gauge Reading 96 PSI (Engine Off)

The most definitive “smoking gun” symptom of a failed 5.7 Hemi oil pressure sensor is not a low reading, but an impossibly high one. Numerous owners report turning the key to the “on” position (without starting the engine) and watching the oil pressure gauge sweep to its maximum value, such as 96 PSI, and stay there.

This is physically impossible. With the engine off, the oil pressure is 0 PSI. This erroneous reading indicates a “Circuit High” fault (see DTC P0523 below). The sensor’s internal resistance has failed, or the wiring is damaged, sending a maximum voltage signal to the Powertrain Control Module (PCM). This symptom conclusively proves the sensor or its wiring is the problem.

Sensor Failure vs. Pump Failure: A Data-Driven Comparison

Before starting any repair, it is critical to determine if you have a faulty sensor (a cheap, easy fix) or a failing oil pump (an engine-destroying emergency). A failing oil pump will always be accompanied by severe mechanical noise.

Bad Sensor (Electrical) vs. Failing Pump (Mechanical)

| Symptom | Bad Oil Pressure Sensor | Failing Oil Pump (Mechanical Emergency) |

| Check Engine Light | Yes (DTCs P0520-P0524) [3, 5, 9] | Yes (but always with other symptoms below) |

| Oil Pressure Gauge | Reads 0 PSI OR Max PSI (e.g., 96 PSI) | Reads legitimately low (e.g., <10 PSI at idle) |

| Gauge Behavior | Erratic, intermittent, or stuck at one value [2] | Drops consistently as RPMs drop |

| Symptom (Engine OFF) | Gauge may read > 0 PSI | Gauge reads 0 PSI (Normal) |

| Engine Noise | Normal | Loud whining, grinding, or clunking [28, 29, 30] |

| Engine Temperature | Normal | Engine overheating (oil provides cooling) [28, 31] |

Decoding the Trouble Codes: P0520, P0523, and the TSB

The check engine light codes confirm the electrical nature of the fault. The most common code, P0520, is the specific subject of NHTSA Technical Service Bulletin 18-034-14.

Chrysler released this TSB on June 06, 2014, for 2013-2014 models, including the Ram 1500, Charger, 300, and Grand Cherokee equipped with the 5.7L engine. The TSB was created to address customer complaints of a Malfunction Indicator Lamp (MIL) caused by DTC P0520. The official fix instructs technicians to “replace the oil pressure sensor with a revised part” , confirming the original sensors were defective.

Common 5.7 Hemi Oil Pressure DTCs Explained

| DTC | Full Name | What It Means |

| P0520 | Engine Oil Pressure Sensor/Switch Circuit [5, 23, 32] | The PCM has detected a general electrical fault in the sensor circuit. This is the official TSB code. |

| P0523 | Engine Oil Pressure Sensor/Switch Circuit High [4, 32] | The circuit is open or shorted, sending a signal of maximum pressure. This is the code that causes the “96 PSI” symptom. |

| P0522 | Engine Oil Pressure Sensor/Switch Circuit Low [32] | The circuit is shorted to ground, sending a signal of zero pressure. This causes the “0 PSI” symptom.[27] |

| P0524 | Engine Oil Pressure Too Low [3, 32] | This is the dangerous one. The sensor is reporting that oil pressure is truly too low. While it can be a bad sensor, this code must be verified with a mechanical gauge, as it could mean actual low oil pressure from a bad pump or low oil level.[33, 34] |

How to Replace the 5.7 Hemi Oil Pressure Sensor (DIY Guides)

Required Tools & Official Mopar Part Numbers

The Part:

- Primary Part Number (2005-2016): Mopar P/N 5149062AB. This is the official revised part listed in the TSB that supersedes older, faulty versions like 5149062AA and 68060337AA.

- Later Models (2019+): Newer 5.7L engines may use a different part, such as Mopar P/N 68334877AA. Always verify the part number with your vehicle’s VIN.

The Tools:

- Required for ALL models:

- Oil Pressure Sensor Socket: This is a specialty deep socket. It is 1 1/16-inch 10 or its metric equivalent, 27mm.

- Ratchet and various extensions.

- Shop Rags.

- Dielectric Grease (for the electrical connector).

- Brake Parts Cleaner (to clean the area).

- Required ONLY for Charger/300/Magnum:

- Serpentine Belt Tensioner Tool.

- Socket Set (10mm, 13mm, 15mm, 16mm).

Guide 1 (Easy): Ram 1500 & Jeep Grand Cherokee Replacement

- Difficulty: 2/10 (Beginner)

- Time: 20-30 minutes

- Safety: Ensure the engine is cool to the touch.

- Locate Sensor: From the front of the vehicle, locate the sensor on the driver’s side of the engine block, adjacent to the oil filter housing.

- Disconnect: Slide the red locking tab on the electrical connector back (away from the sensor). Press the black release tab and firmly pull the electrical connector off.

- Remove: Place a shop rag below the sensor to catch any oil drips. Using the 1 1/16″ (or 27mm) sensor socket and a ratchet, turn the sensor counter-clockwise to remove it from the engine block.

- Install New Sensor: Thread the new Mopar sensor (P/N 5149062AB) in by hand to ensure it does not cross-thread. Once hand-tight, use the socket to snug it down. Do not overtighten.

- Reconnect: Apply a small dab of dielectric grease to the pins inside the electrical connector. Push the connector onto the new sensor until it “clicks,” then slide the red locking tab back in place to secure it.

- Clear Codes: Use an OBD-2 scanner to clear the stored DTCs from the computer. Start the engine and verify the gauge reads correctly and there are no leaks.

Guide 2 (Difficult): Dodge Charger, 300 & Magnum Replacement

- Difficulty: 7/10 (Advanced)

- Time: 2-4 hours

- Prep: Disconnect the negative battery terminal.

- Remove Intake: Remove the plastic engine cover and the entire air intake tube and airbox assembly.

- Remove Belt: Use a serpentine belt tool or a long breaker bar to release the tension on the belt tensioner, and slide the serpentine belt off the pulleys.

- Remove Alternator: This is the most critical step for access. Disconnect the alternator’s electrical connectors and the main power lead (13mm nut). Remove the alternator’s main mounting bolts (typically 15mm). Pry the alternator loose and lift the entire unit out of the engine bay.

- Remove EGR (if needed): On some models, the EGR valve may also need to be unbolted and moved to the side for adequate clearance.

- Access & Replace Sensor: You can now see and access the oil pressure sensor deep in the engine valley. Use your sensor socket with a long extension to reach down, disconnect the connector, and replace the sensor as described in “Easy” Guide steps 4-6.

- Reassemble: Reinstall all components in the exact reverse order of removal. This is the most complex part of the job. Ensure the alternator is seated correctly and the serpentine belt is routed properly on all pulleys.

- Clear Codes: Reconnect the battery. Start the vehicle, check for leaks, and verify the oil pressure gauge is functioning. Clear any stored DTCs.

Data-Driven Analysis: Costs, Specs, and Testing

5.7 Hemi Oil Pressure Sensor Replacement Cost: DIY vs. Pro

The replacement cost is not one-size-fits-all. It is dictated entirely by the sensor’s location and the associated labor time. A shop charges for labor, so the “difficult” location on car platforms is drastically more expensive.

Cost Comparison: Easy vs. Difficult Platform

| Vehicle Platform | DIY Cost (Parts + Tool) | Professional Cost (Estimate) | Labor Time (TSB Est.) |

| Ram 1500, Grand Cherokee | Part: ~$39 Socket: ~$15 [22] Total: ~$54 | ~$179 (avg. $39 part + $140 labor) | 0.4 Hours |

| Dodge Charger, 300, Magnum | Part: ~$39 Socket: ~$15 [22] Total: ~$54 | $350 – $650+ (Shops charge for intake/alternator removal) | 0.7 Hours (TSB) / 2-3 Hours (Shop) [9, 40] |

Analysis: The official TSB lists a warranty labor time of 0.4 hours for a Ram 1500 and 0.7 hours for a Charger. However, this warranty time is famously optimistic. A non-warranty customer repair will be billed at a standard book rate, which can be 2-3 hours for the “difficult” location, making the professional cost on the car platforms at least 3-4 times higher than on a truck.

What is Normal Oil Pressure for a 5.7 Hemi? (PSI Specs)

Many owners become worried when they see their working gauge fluctuating. This is normal. Oil pressure is not a static number; it varies directly with engine temperature, oil viscosity (e.g., 5W-20 vs 5W-30), and, most importantly, engine RPM.

5.7 Hemi Normal Operating PSI (When Warm)

| Engine State | Typical PSI Range (Hot Engine) |

| Hot Idle (In Drive) | 27 – 45 PSI |

| Highway Cruising (~2-3k RPM) | 45 – 60 PSI |

| Wide Open Throttle (WOT) | ~55 – 78 PSI |

| Cold Start (Idle) | ~50 – 65 PSI (Pressure is highest when oil is cold/thick) |

If your pressure is consistently low even after replacing the sensor, this may indicate oil starvation. This is a known cause of the dreaded Hemi lifter tick, which requires immediate mechanical attention.

How to Test an Oil Pressure Sensor

- Method 1 (The Professional Way): The only 100% accurate test is to use a mechanical oil pressure gauge. This involves removing the electrical sensor, temporarily installing the mechanical gauge in its port, starting the engine, and reading the real pressure. If the mechanical gauge shows 40 PSI and the dash gauge shows 0 PSI, the sensor is confirmed bad.

- Method 2 (The DIY Way): You can test the sensor and its circuit with a multimeter. However, the simplest and most effective diagnosis for a 5.7 Hemi is the “engine off” test. If your dash gauge reads high pressure (like 96 PSI) when the engine is off, the sensor is definitively bad.

Conclusion: The Final Word

The 5.7 Hemi’s oil pressure sensor is a common failure point, but it is a highly diagnosable and fixable issue.

- Location Varies: The sensor is easy to access on Ram 1500s and Grand Cherokees (front, driver’s side, by oil filter).10 It is difficult on Chargers and 300s (under the intake/alternator).

- Symptoms are Electrical: An erratic gauge, or one that reads 0 PSI or a maxed-out 96+ PSI, is a classic sign of a failed sensor, not a failed pump.

- It’s a Known Defect: DTC P0520 is the subject of Chrysler TSB 18-034-14, which mandates a revised part for this exact problem.

- The Part is Simple: The revised, official Mopar part for most 2005-2016 models is 5149062AB.

- The Cost Varies: The repair is cheap for DIY-ers (~$54) but can be very expensive on car platforms (~$500+) if done by a professional, purely due to the labor required for access.

Frequently Asked Questions (FAQ)

Q: What are the symptoms of a bad oil pressure sensor on a 5.7 Hemi?

A: The most common symptoms are an erratic oil pressure gauge, the gauge reading 0 PSI, or the gauge reading max PSI (like 96) even when the engine is off. This is often accompanied by a flickering oil light or a Check Engine Light with codes P0520, P0521, P0522, P0523, or P0524.

Q: Where is the oil pressure sensor on a 2014 Ram 1500 5.7 Hemi?

A: It is in an easy-to-access location on the front of the engine block, on the driver’s side, right next to the oil filter housing.

Q: What does code P0520 mean on a 5.7 Hemi?

A: P0520 means the engine’s computer (PCM) has detected a malfunction in the oil pressure sensor’s electrical circuit. It’s a very common code and was the subject of an official Technical Service Bulletin (TSB 18-034-14) from Chrysler, pointing to a faulty sensor.

Q: Can I drive with a bad oil pressure sensor?

A: It is highly discouraged. When the sensor is bad, you can no longer trust your gauge. You have no way of knowing if you have safe oil pressure or if your engine is seconds away from catastrophic failure. You should not drive the vehicle until it is confirmed to be just the sensor.

Q: How much does it cost to replace a 5.7 Hemi oil pressure sensor?

A: The cost depends on your vehicle. For a Ram 1500 or Jeep, a shop may charge around $179. For a Dodge Charger or 300, the cost is much higher, from $350 to over $600, because the alternator must be removed to access the sensor. The part itself is cheap, around $39-$54.

Q: What is the Mopar part number for a 5.7 Hemi oil pressure sensor?

A: The most common revised part number for 2005-2016 models is Mopar 5149062AB. This part supersedes the older, failure-prone versions.

Q: What is normal oil pressure for a 5.7 Hemi at idle?

A: Once the engine is fully warm, a normal oil pressure at idle (in drive) is typically between 27 and 45 PSI.41 It will be higher on a cold start (50-65 PSI).