6.7 Cummins Heater Hose Connector Leak: Fix it now with these power-packed solutions

The 6.7 Cummins heater hose connector is leaking and can be fixed with a replacement connector. The leaking connector can cause a loss of heat and potentially lead to smoke and overheating.

If you are experiencing a coolant leak from your 6. 7 Cummins heater hose connector, it is important to address the issue promptly to prevent further damage to your engine. We will discuss the causes and symptoms of a heater hose connector leak and provide a solution to fix the issue.

By understanding the signs and taking appropriate action, you can ensure the longevity and performance of your vehicle’s cooling system.

The Importance Of Addressing A Heater Hose Connector Leak

|

The Importance of Addressing a Heater Hose Connector Leak Ignoring a heater hose connector leak can lead to significant consequences. One of the reasons why neglecting such a leak is a big mistake is because it can result in coolant leakage. The coolant/antifreeze contains corrosion inhibitors that coat the surfaces inside the cooling system, including the heater core. When the corrosion inhibitors are depleted, the cooling system can become corroded, filled with contaminants, and may even start to leak. This can cause a range of problems, such as low coolant level, overheating engine, loss of heat, and a fruity smell in the car. Additionally, a heater hose connector leak can also cause the heater hoses to feel soft to the touch and make crackling noise when squeezed. These symptoms can indicate a deteriorating hose that is at risk of bursting, leading to a sudden coolant leak. Therefore, it is crucial to address a heater hose connector leak promptly to avoid further damage to the cooling system and potential engine overheating. |

Identifying A Heater Hose Connector Leak

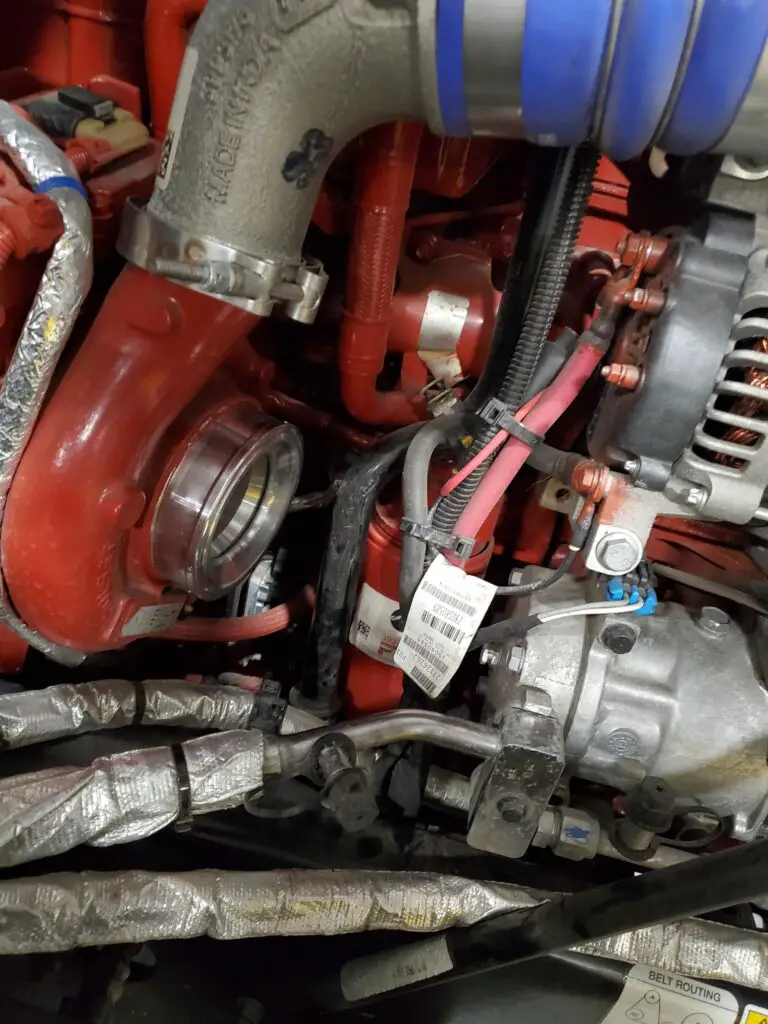

Identifying a heater hose connector leak in your 6.7 Cummins is crucial to prevent further damage to your vehicle’s cooling system. Common signs and symptoms of a heater hose connector leak include a smell of coolant when the hood is ajar, no heat coming out of the heater, steam coming out from under the hood, low coolant level, coolant leak, temperature gauge running very hot, soft heater hoses, and crackling noise when squeezed.

To diagnose a heater hose connector leak, you can start by inspecting the hoses for any visible signs of leakage, such as wet spots or drips. You can also perform a pressure test on the cooling system to check for any sudden drops in pressure. Additionally, if your car windows are fogging for no reason and your engine is overheating, it could be a sign of a damaged heater core.

If you suspect a heater hose connector leak in your 6.7 Cummins, it is essential to address the issue promptly. Ignoring a leak can lead to coolant loss, overheating, and potential engine damage. Consult a professional mechanic or refer to your vehicle’s user manual for specific instructions on how to fix a heater hose connector leak.

Power-packed Solutions To Fix A Heater Hose Connector Leak

Power-Packed Solutions to Fix a Heater Hose Connector Leak

Solution 1: Replacing the leaking connector with a high-quality aftermarket option.

Solution 2: Repairing the connector using a reliable sealant or adhesive.

Solution 3: Upgrading to a more durable and reliable connector system.

Solution 3a: Exploring Options For Upgraded Connector Systems

One option for upgrading your heater hose connector to address the leak issue is to consider coolant bypass kits. These kits provide an alternative pathway for coolant flow which can help alleviate pressure on the connector and reduce the likelihood of leaks. By redirecting coolant flow, bypass kits can provide a more efficient cooling system and extend the lifespan of your connector.

Another option to consider is the Sinister Diesel Coolant Riser Kit. This kit replaces the stock heater hose connector with a more durable and reliable riser fitting. The Sinister Diesel Coolant Riser Kit is specifically designed for 6.7 Cummins engines and provides a seamless connection that is less prone to leaks.

If you prefer a more straightforward solution, you can explore upgraded heater hose connector kits. These kits typically include stronger connectors, reinforced hoses, and improved seals to prevent leaks. Upgraded connector kits are often designed to be direct replacements for the original components, making installation easier and more convenient.

Solution 3b: Benefits And Considerations Of Upgrading To A More Durable Connector System

In the context of 6.7 Cummins heater hose connector leaks, upgrading to a more durable connector system offers several benefits and considerations. Firstly, it enhances reliability and durability, ensuring a longer lifespan for the connector system. This leads to improved performance and efficiency, providing a more consistent flow of coolant. Additionally, the use of a more durable connector can potentially result in cost savings in the long run, as it reduces the need for frequent repairs or replacements. By investing in a high-quality and reliable connector system, users can mitigate the risks associated with hose leaks and minimize the downtime caused by coolant issues. Overall, upgrading to a more durable connector system is an effective solution for addressing the challenges posed by 6.7 Cummins heater hose connector leaks.

Steps To Fix A Heater Hose Connector Leak

To start fixing a heater hose connector leak, you will need to gather the following tools and materials:

- Replacement hose connector

- Repair sealant (if applicable)

- Wrench set

- Socket set

- Screwdriver set

- Pliers

- Bucket or container

- Rags or towels

Before proceeding with the repair, it is important to prepare the area properly. This includes:

- Ensuring the engine is cooled down

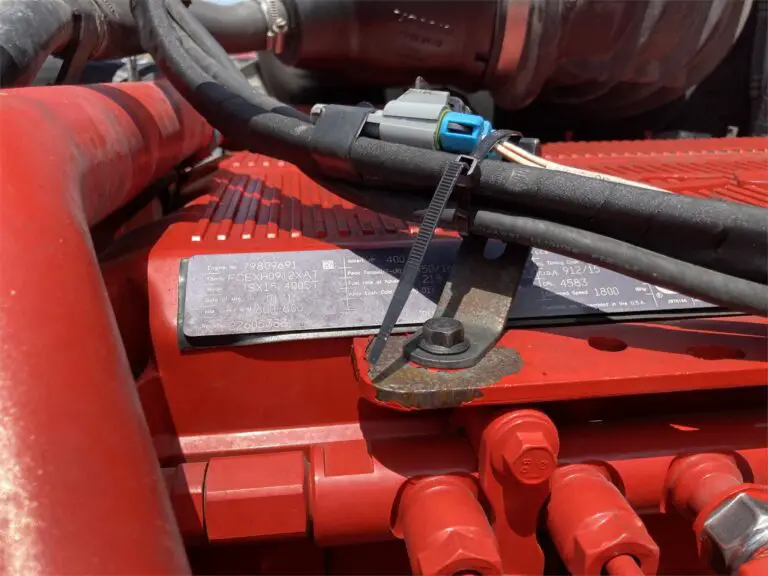

- Locating the heater hose connector

- Removing any obstructions or debris around the connector

To remove the old or damaged connector, follow these steps:

- Use a wrench or socket set to loosen and remove any clamps securing the connector.

- Disconnect the hose from the connector by gently twisting and pulling.

- Inspect the connector for any additional screws or fasteners and remove them if necessary.

- Carefully remove the old connector from the heater hose.

Depending on the extent of the damage, you can either install a new connector or apply a repair sealant. Follow these steps:

- If installing a new connector, slide it onto the heater hose and ensure a tight fit.

- Use clamps to secure the new connector in place.

- If applying a repair sealant, carefully follow the manufacturer’s instructions.

- Allow the sealant to cure according to the specified time.

After the repair, it is important to test for leaks and ensure proper functionality. Follow these steps:

- Reconnect any disconnected hoses.

- Tighten all clamps and fasteners.

- Refill the cooling system with the appropriate coolant.

- Start the engine and monitor for any signs of leaks or irregularities.

- Check for proper heat output from the heater.

Preventing Future Heater Hose Connector Leaks

Preventing future heater hose connector leaks is crucial for maintaining the efficiency and longevity of your vehicle’s cooling system. Regular maintenance and inspection are key to identifying any signs of wear or damage promptly. Here are some tips to help you avoid future leaks:

- Inspect the heater hoses regularly for any signs of cracks, leaks, or bulges. Pay attention to the condition of the connectors as well.

- Check the coolant levels regularly and ensure it is at the appropriate level. Low coolant levels can put added strain on the heater hoses.

- Replace worn-out or damaged hoses immediately. Do not delay in addressing any signs of wear or damage.

- Consider using high-quality and durable heater hoses that are designed to withstand extreme temperature and pressure conditions.

- Flush and refill the coolant system as recommended by the vehicle manufacturer to maintain the proper functioning of the system.

- Ensure that the heater hoses are properly connected and secured to prevent any potential leaks.

By following these maintenance and inspection tips, you can prevent future heater hose connector leaks and avoid costly repairs down the road.

Frequently Asked Questions For 6.7 Cummins Heater Hose Connector Leak

How Do I Stop My Heater Hose From Leaking?

To stop your heater hose from leaking, you should check for signs of corrosion and contamination in the cooling system. If the coolant is depleted or the heater core is damaged, it can cause leaks. It’s best to consult with a mechanic for professional repair and not attempt a DIY fix unless skilled and experienced.

What Causes Heater Core Hose To Leak?

The heater core hose can leak due to depleted corrosion inhibitors in the coolant, leading to corrosion and contamination in the cooling system. Signs of a bad heater hose include coolant smell, no heat, steam, low coolant level, and crackling noise.

If the heater core is leaking, you may experience foggy windows, overheating, fruity smell in the car, and a cold cabin. Seek professional assistance for heater core repair.

What Are The Symptoms Of A Bad Heater Hose?

Symptoms of a bad heater hose include coolant smell, lack of heat, steam, low coolant level, coolant leak, hot temperature gauge, soft hoses, and crackling noise when squeezed. If you suspect a bad heater hose, it’s best to consult a mechanic.

How Can I Tell If My Heater Core Is Leaking?

If your car windows fog up for no reason, your engine overheats, and you smell a fruity odor in your car, your heater core may be leaking. It’s best to take your car to a mechanic for repair, as DIY fixes require experience and skill.

Conclusion

To prevent further damage and ensure optimal performance of your 6. 7 Cummins engine, it is crucial to address a heater hose connector leak as soon as possible. By replacing the faulty connector with a high-quality HVAC heater hose connector, you can restore leak-free performance.

Neglecting this issue could lead to coolant leaks, overheating, and potential engine damage. Remember, regular maintenance and timely repairs are key to keeping your engine running smoothly. Take action now to avoid costly repairs in the future.