Torque Specs for Chevy 350: Ultimate Guide for Precision

Torque specs are crucial for any engine work. Chevy 350 engines are no exception.

Understanding torque specs ensures your engine runs smoothly and safely. Incorrect torque can lead to engine damage or failure. In this post, we’ll cover essential torque specs for Chevy 350 engines. Whether you’re a seasoned mechanic or a DIY enthusiast, knowing these specs is key.

Torque settings affect the performance and longevity of your engine. We’ll explore various components and their specific torque requirements. Stay tuned to get all the details you need for your Chevy 350 engine. Proper torque specs mean better performance and reliability. Let’s dive into the specifics to keep your engine in top shape.

Introduction To Chevy 350 Torque Specs

If you own a Chevy 350 or are simply fascinated by its mechanics, understanding the torque specs is crucial. These specs ensure that every bolt and nut in your engine is tightened to the correct level. This blog post will guide you through the essentials of Chevy 350 torque specs, making it easy to grasp even if you’re new to the topic.

Importance Of Proper Torque

Why should you care about proper torque? Well, imagine building a piece of furniture without tightening the screws properly. It would wobble and could fall apart, right? The same goes for your engine. Using the correct torque specs ensures that everything is held together tightly and functions smoothly. It helps avoid potential problems like leaks, part failures, or even engine damage.

In short, proper torque means a longer life for your engine and fewer headaches for you!

Overview Of The Chevy 350 Engine

The Chevy 350 is a small-block V8 engine that has earned a legendary status among car enthusiasts. Introduced in the late 1960s, it became famous for its reliability, performance, and versatility. Whether you own a classic muscle car or a modern street machine, the Chevy 350 offers a solid foundation.

This engine is known for its robust design and ability to handle power upgrades. It has been used in a variety of Chevrolet cars and trucks, making it one of the most popular engines of all time.

Torque Specs Table

| Component | Torque Spec (lb-ft) |

|---|---|

| Head Bolts | 65 |

| Intake Manifold Bolts | 30 |

| Exhaust Manifold Bolts | 20 |

| Main Cap Bolts | 70 |

| Rod Bolts | 45 |

As you can see, each component has its specific torque requirement. Sticking to these specs ensures everything in your Chevy 350 engine is secure and ready to perform at its best.

Remember, when it comes to engines, it’s always better to be safe than sorry. So, grab your torque wrench, follow these specs, and keep your Chevy 350 running smoothly!

Tools And Equipment

When working on your Chevy 350, having the right tools and equipment is crucial. Proper torque specs ensure your engine runs smoothly and efficiently. Below, we discuss essential tools and safety gear needed for this task.

Essential Tools

Torque wrench is a must-have. It allows you to tighten bolts to the correct specifications. Socket sets are necessary for various bolt sizes on the Chevy 350. Invest in quality ones for durability.

Extension bars help reach bolts in tight spaces. They come in handy during engine assembly. Screwdrivers are also essential. Flathead and Phillips types cover most needs.

Feeler gauges measure gaps accurately. They ensure parts fit perfectly. Impact wrench speeds up the process. It’s useful for stubborn bolts. A sturdy workbench provides a stable surface for tasks.

Safety Gear

Safety glasses protect your eyes from debris. They are essential during mechanical work. Gloves prevent hand injuries. Choose ones with good grip and comfort.

Ear protection is important. Engine work can be loud. Use earplugs or earmuffs. Wear a dust mask if working in dusty conditions. It keeps your lungs safe.

Steel-toed boots protect your feet. They are vital in a workshop setting. Ensure your clothing is snug. Loose clothing can get caught in machinery. A first aid kit should be accessible. It’s essential for any workshop.

Cylinder Head Bolt Torque

Understanding the proper torque specifications for the Chevy 350 cylinder head bolts is crucial. Ensuring that the bolts are tightened correctly can prevent engine issues. Properly torqued bolts help maintain the integrity of the engine. This section will guide you through the sequence and specifications for cylinder head bolt torque.

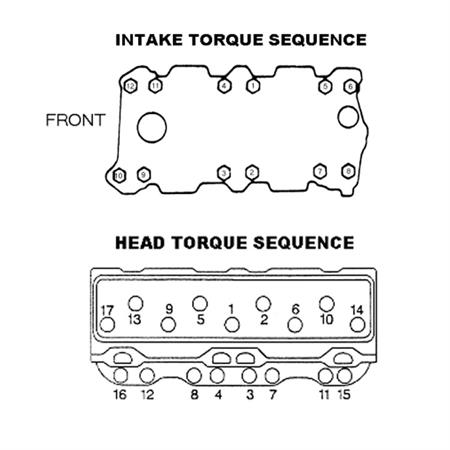

Sequence For Tightening

The sequence for tightening the cylinder head bolts is important. Following the correct pattern ensures even pressure distribution. Begin with the center bolts and work your way outwards. This method prevents warping and ensures a secure fit. Refer to the manual for the exact sequence. The pattern typically follows a spiral or cross pattern.

Torque Specifications

The torque specifications for the Chevy 350 cylinder head bolts are precise. Using a torque wrench is essential to achieve the correct torque. For the Chevy 350, the cylinder head bolts should be torqued in stages. Start with an initial torque of 25 ft-lbs. Then, proceed to 45 ft-lbs. Finally, torque the bolts to 65 ft-lbs. Ensure each bolt is tightened to the specified value. Over or under-torquing can cause engine damage.

Main Cap Bolt Torque

The Chevy 350 engine is iconic in the automotive world. One critical aspect of its assembly is the main cap bolt torque. Proper torque ensures the engine runs smoothly and lasts longer. In this section, we focus on the main cap bolt torque for the Chevy 350.

Proper Tightening Method

Proper tightening of the main cap bolts is crucial. This avoids engine damage and ensures longevity. First, clean all threads thoroughly. Then, apply a thin layer of engine oil to the bolt threads. This reduces friction and ensures accurate torque readings. Tighten the bolts in three stages. This method ensures even pressure distribution.

Torque Values

For the Chevy 350, the torque values are specific. The main cap bolts should be tightened to 70 ft-lbs. Always use a calibrated torque wrench. This ensures precision and safety. Remember to follow the tightening sequence. This avoids warping and uneven pressure.

Connecting Rod Bolt Torque

The connecting rod bolt torque is a critical aspect of engine assembly. Proper torque ensures the engine runs smoothly and lasts longer. Incorrect torque can lead to engine failure or damage. Understanding and applying the correct torque specs for a Chevy 350 is essential for optimal performance.

Step-by-step Instructions

Start by gathering the necessary tools. You will need a torque wrench and the proper socket size. Make sure the connecting rod bolts are clean. Dirt can affect the torque readings. Follow these steps:

1. Place the connecting rod cap onto the connecting rod.

2. Hand-tighten the connecting rod bolts.

3. Set your torque wrench to the initial torque setting.

4. Tighten the bolts in small increments. This ensures even pressure.

5. Once the initial torque is reached, reset the wrench to the final torque setting.

6. Tighten the bolts to the final torque specification.

7. Double-check all bolts to ensure they are properly torqued.

Torque Settings

The Chevy 350 engine has specific torque settings for connecting rod bolts. These settings are crucial for engine stability. The initial torque setting is 20 foot-pounds. The final torque setting is 45 foot-pounds. Always use a calibrated torque wrench for accuracy.

Proper torque ensures the engine components are secure. This reduces the risk of engine wear and tear. Always refer to the engine manual for any variations. Each engine may have slight differences. Following these settings ensures optimal engine performance.

Credit: www.motortrend.com

Intake Manifold Bolt Torque

When it comes to working on a Chevy 350 engine, knowing the correct torque specs for the intake manifold bolts is crucial. Proper tightening ensures a good seal and prevents leaks. This guide will help you understand the Intake Manifold Bolt Torque for your Chevy 350, making your job easier and more efficient.

Tightening Sequence

Before diving into the torque specifications, it’s important to follow the correct tightening sequence. Tightening the bolts in the correct order helps to evenly distribute the pressure, ensuring a proper seal. Here’s a simple step-by-step sequence you can follow:

- Start from the center and work your way out.

- Always tighten bolts in a crisscross pattern.

- Gradually increase the torque in stages.

Torque Specifications

Once you have the tightening sequence down, it’s time to focus on the torque specifications. For the Chevy 350 intake manifold bolts, the torque specs are as follows:

| Stage | Torque (lb-ft) |

|---|---|

| Initial Pass | 15 |

| Final Pass | 25 |

It’s essential to use a reliable torque wrench to ensure these specs are met accurately. Over-tightening can strip the threads, while under-tightening can lead to leaks.

In conclusion, by following the correct tightening sequence and adhering to the specified torque, you can ensure a well-sealed and efficient intake manifold on your Chevy 350. Happy wrenching!

Exhaust Manifold Bolt Torque

Working on the exhaust manifold of your Chevy 350? One of the most important steps is ensuring the bolts are tightened correctly. If you don’t, it can lead to leaks, poor performance, and even damage over time. In this section, we’ll walk you through the correct process and the required torque specs to keep your engine running smoothly.

Correct Tightening Process

Before you start tightening the bolts, make sure the exhaust manifold is aligned properly. It’s always a good idea to clean the bolts and threads to ensure a snug fit. Here’s a simple step-by-step process to follow:

- Begin by hand-tightening the bolts to make sure they’re threading correctly.

- Using a torque wrench, tighten the bolts in a crisscross pattern. This ensures even pressure and a better seal.

- Gradually increase the torque in stages. Don’t go straight to the final torque spec in one go.

Remember, patience is key here. Rushing through this process can cause issues later on.

Torque Requirements

Now, let’s get to the numbers. The torque specs for the exhaust manifold bolts on a Chevy 350 are:

| Component | Torque Spec (lb-ft) |

|---|---|

| Exhaust Manifold Bolts | 20-30 |

It’s important to use a reliable torque wrench to achieve these specs accurately. Over-tightening can strip the threads, while under-tightening can lead to leaks. It’s a fine balance, but with the right tools and a bit of care, you can get it just right.

In conclusion, properly torquing the exhaust manifold bolts on your Chevy 350 is a critical step to ensure your engine runs efficiently. By following the correct process and adhering to the specified torque requirements, you’ll avoid common pitfalls and keep your vehicle in top shape.

Credit: www.speedwaymotors.com

Common Mistakes To Avoid

When working on the Chevy 350, knowing the torque specs is vital. Mistakes can lead to serious damage. Here are common mistakes to avoid.

Over-tightening Issues

Over-tightening bolts can strip threads. This can cause bolt failure. It can also warp the engine components. This leads to poor performance. Always use a torque wrench. Follow the manufacturer’s specs.

Under-tightening Risks

Under-tightening bolts is equally risky. Loose bolts can cause leaks. They can also result in parts coming apart. This can lead to engine damage. Ensure each bolt is tightened correctly. Check specs to avoid mistakes.

Maintenance Tips For Torque Integrity

Maintaining the torque integrity of your Chevy 350 engine is crucial. Follow these tips to ensure your engine runs smoothly and efficiently. Regular inspections and proper storage of tools can make a big difference.

Regular Inspections

Inspect your engine’s torque specs regularly. Look for any signs of wear or damage. Check bolts and nuts for tightness. Loose parts can cause serious issues. Using a torque wrench, verify the torque settings. This tool helps maintain the correct pressure on engine components.

Follow the manufacturer’s guidelines for torque specs. These numbers ensure the engine parts are secure. Regular checks can prevent costly repairs. Keep a log of your inspections. This helps track any changes in the engine’s performance.

Proper Storage Of Tools

Store your tools properly to maintain their accuracy. A torque wrench is sensitive. Keep it in a dry, clean place. Avoid exposing it to extreme temperatures. This can affect its calibration. Regularly check your torque wrench’s calibration. Follow the manufacturer’s instructions for maintenance.

Use toolboxes or cases to organize your tools. This prevents damage and loss. Clean your tools after each use. Dirt and grime can affect their performance. Proper tool storage ensures accurate torque readings. This helps maintain your Chevy 350’s torque integrity.

Credit: paceperformance.com

Frequently Asked Questions

What Is The Torque On A 350 Sbc Intake?

The torque for a 350 SBC intake manifold bolts is typically 25-30 ft-lbs. Use a cross pattern for tightening.

What Are The Torque Specs On A Small Block Chevy?

The torque specs for a small block Chevy are: cylinder head bolts – 65 ft-lbs, intake manifold bolts – 30 ft-lbs, and main cap bolts – 70 ft-lbs.

What Is The Torque On The Starter Bolts On A 350 Chevy?

The torque on the starter bolts for a 350 Chevy should be 35 foot-pounds. Ensure bolts are tightened evenly.

What Are The Specs Of The Chevy 350 Engine?

The Chevy 350 engine has a 5. 7L V8 configuration, producing 195-370 horsepower, 260-380 lb-ft torque, and a 4. 00-inch bore.

Conclusion

Understanding the torque specs for your Chevy 350 is crucial. Proper torque ensures engine performance and longevity. Always follow the manual for accurate specifications. Incorrect torque can cause engine damage. Use a reliable torque wrench for precise adjustments. Regular maintenance keeps your Chevy 350 running smoothly.

Stay informed, stay safe, and enjoy your ride!