5.7 Hemi Water Pump Bolt Torque Specs: The Definitive Guide 2025

The Answer First: 5.7 Hemi Water Pump Bolt Torque Specs (ft-lbs & N·m)

When replacing the water pump on a 5.7L Hemi V8, applying the correct torque to the fasteners is the most critical step for achieving a leak-free seal. Applying too little torque will cause a coolant leak; applying too much can crack the pump housing or timing cover, leading to a catastrophic failure.

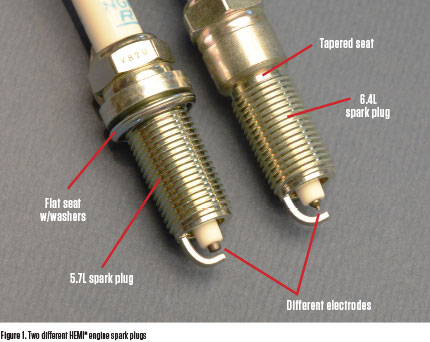

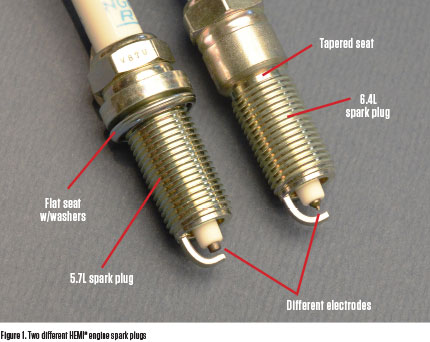

The 5.7 Hemi water pump assembly is secured to the engine block and timing cover using two different types of fasteners: M8 bolts and nuts (on studs). These have different torque values. Using the bolt specification on the nut will strip it instantly.

Here are the definitive, factory-specification torque values required for the job.

5.7 Hemi Water Pump: The Torque Spec Guide

Get the right torque specs and tightening sequence to prevent leaks and damage.

This is the critical specification for the (8) M8 bolts that secure the water pump to the engine block.

Why Torque Specs Are Critical

Incorrect torque is the number one cause of repeat failures. Applying the right pressure ensures the gasket seals perfectly without damaging parts.

Under-Tightened

Causes gasket leaks, coolant loss, and engine overheating.

Over-Tightened

Can break bolts, crack the pump housing, or warp the sealing surface.

Signs of a Failing Water Pump

A failing pump rarely just stops. It usually provides warning signs. Visible coolant leaks are the most common symptom, followed by engine overheating.

5.7 Hemi Torque Specifications

The 5.7 Hemi water pump uses two different bolt sizes that must be torqued correctly. Other nearby components are also listed for reference.

| Component / Bolt | Size (Qty) | Torque (ft-lbs) | Torque (Nm) |

|---|---|---|---|

| Water Pump to Block | M8 (x8) | 18 | 25 |

| Water Pump to Timing Cover | M6 (x4) | 8 | 10 |

| Water Pump Pulley | M6 (x4) | 8 | 10 |

| Tensioner Pulley Bolt | M10 (x1) | 33 | 45 |

Data based on Mopar service manuals. Always confirm with your vehicle’s specific service manual before proceeding.

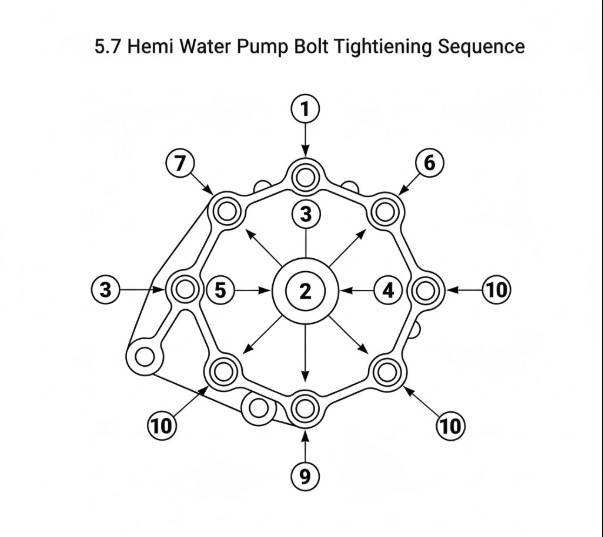

Bolt Tightening Sequence

To ensure an even seal, tighten the bolts in a crisscross pattern in stages. First, snug all bolts by hand. Then, torque in the sequence shown.

Table Title: 5.7 Hemi Water Pump & Cooling System Torque Specs

Rationale: This table provides the primary, skimmable answer to the user’s query, optimizing for user experience and search engine snippet capture. It consolidates all critical torque values from multiple technical sources into one easy-to-read reference.

| Fastener / Component | Torque (ft-lbs) | Torque (N·m) | Notes & Source(s) |

| Water Pump Bolts (M8) | 21 ft-lbs | 28 N·m | The standard, most common spec for Gen III 5.7L & 5.7L Eagle Hemi engines |

| Water Pump Nuts | 9 ft-lbs | 12 N·m | Secures the pump to the timing cover studs. Crucially different spec |

| Thermostat Housing Bolts | 21 ft-lbs | 28 N·m | Same specification as the main M8 water pump bolts |

| Alternate Spec (Cars) | 18 ft-lbs | 24 N·m | A revised spec noted for some 2014+ Dodge cars. See explanation below |

Why the Confusion? 21 ft-lbs vs. 18 ft-lbs Explained

A search for this specification reveals two different numbers: 21 ft-lbs and 18 ft-lbs. This confusion is warranted, as both figures appear in reputable technical documentation.

1. The 21 ft-lbs (28 N·m) Standard

This is the most widely published and accepted torque specification for the Gen III Hemi. Multiple high-authority technical sources, including Summit Racing and Brian Tooley Racing, cite 21 ft-lbs for the water pump bolts. This specification is confirmed for both the standard 5.7L Hemi (2003-2008) and the 2009+ 5.7L “Eagle” Hemi with Variable Valve Timing (VVT).

For the vast majority of 5.7 Hemi applications, especially Ram trucks (1500, 2500) and SUVs (Durango, Grand Cherokee), 21 ft-lbs (28 N·m) is the correct and definitive torque specification.

2. The 18 ft-lbs (24 N·m) Revision

This is not a “forum myth.” The 18 ft-lbs specification comes directly from Mopar’s enthusiast resource, Dodge Garage. In a detailed water pump replacement guide, the article explicitly states, “For our subject vehicle, a 2014 Dodge Challenger, the correct torque for the water pump mounting bolts is 18 ft.-lbs.”.

This strongly suggests that Mopar issued a revised specification for certain platforms, likely the LX-body cars (Dodge Charger, Dodge Challenger, Chrysler 300) starting around the 2014 model year. This change may be due to a subtle update in gasket material, bolt properties, or the pump housing itself.

Expert Recommendation:

- For Ram Trucks and SUVs (All Years): Use the standard 21 ft-lbs (28 N·m) specification.

- For 2014+ Dodge Charger/Challenger/Chrysler 300: The revised specification of 18 ft-lbs (24 N·m) may be correct. It is best to verify with a model-specific service manual. If 18 ft-lbs is specified, using 21 ft-lbs could over-compress the gasket and lead to a premature leak.

Is Your Hemi Water Pump Failing? Top 5 Symptoms

A water pump failure is not a single event but a chain reaction of mechanical breakdown. Recognizing the early signs can save you from engine damage.

- The Warning Noise (Whining or Grinding): The first sign is often a high-pitched “whining” or “squealing” from the front of the engine that changes with RPM. This is not coolant; it is the sound of the pump’s internal shaft bearing failing as its lubrication is lost.

- The Visual Cue (Pulley Wobble): Once the bearing (Symptom 1) is worn, the entire shaft becomes loose. With the engine off and cool, grab the water pump pulley (where the fan or serpentine belt rides). If you can feel any “play” or wobble it back and forth, the bearing is gone.

- The Telltale Leak (Coolant from the Weep Hole): The pulley wobble (Symptom 2) quickly destroys the pump’s internal shaft seal. By design, a “weep hole” on the bottom of the pump housing allows this leaking coolant to escape. If you see a puddle of pink, orange, or purple coolant under the front of your engine, it is a definitive sign the pump has failed.

- The Cabin Clue (Heater Stops Working): The pump is now failing to circulate coolant effectively. Hot coolant is no longer reaching the heater core inside the cabin, causing your heater to blow cold or lukewarm air even when the engine is warm.

- The Critical Warning (Engine Overheating): This is the final stage. The pump has completely failed, either from a massive leak or a broken internal impeller. Coolant is no longer circulating, and the engine cannot shed its heat, causing the temperature gauge to spike into the red.6 Stop driving immediately to prevent catastrophic engine damage.

Full 5.7 Hemi Water Pump Replacement Guide (DIY)

This is a moderately difficult job that can be completed in 2-4 hours.11 Having the right tools and following the correct procedure is key.

Tools & Parts Required

- New Water Pump & Gasket

- Calibrated Torque Wrench (ft-lbs and in-lbs)

- Socket Set (10mm, 13mm, 15mm sockets and extensions)

- Fan Clutch Wrench Set / Spanner Wrench (for truck models)

- Breaker Bar (for belt tensioner)

- Coolant Drain Pan

- Spill-Free Coolant Funnel

- Plastic Gasket Scraper & Scotch-Brite Pad

- Shop Rags & Brake Cleaner

- 3-4 Gallons of correct Mopar Coolant (HOAT or OAT) and distilled water

Step-by-Step Replacement Procedure

Step 1: Drain the Cooling System

Place a large drain pan under the radiator. Open the petcock on the bottom corner of the radiator and remove the radiator cap to allow the system to drain completely. This is also the perfect time to do a complete cooling system flush.

Step 2: Remove the Fan Clutch (THE MOST COMMON TRAP)

For truck and some SUV models (Ram, Durango), removing the mechanical fan clutch is the hardest part of the job.9 Failure at this step is the #1 reason a DIY repair is abandoned.

STOP! READ THIS! On most 2009-and-newer 5.7L Hemi trucks, the fan clutch nut has REVERSE (LEFT-HAND) THREADS.

- This means CLOCKWISE to loosen (“righty-loosey”).

- This means COUNTER-CLOCKWISE to tighten.

If you attempt to loosen it normally (counter-clockwise), you will only tighten it, potentially breaking the pulley or the pump. Use a fan clutch spanner wrench set to hold the pulley stationary while turning the large nut CLOCKWISE to remove it.

Step 3: Remove Serpentine Belt & Accessories

Use a breaker bar or serpentine belt tool to release the tension on the belt tensioner and slide the belt off the pulleys. Remove the belt tensioner and the idler pulley, as their bolts often pass through the water pump.

Step 4: Detach Hoses & Unbolt the Water Pump

Remove the upper and lower radiator hoses, as well as the smaller heater hoses, from the water pump assembly. Now, prepare to remove the water pump bolts.

Pro-Tip (The Cardboard Trick): The 5.7 Hemi water pump uses multiple M8 bolts of different lengths. A Mopar M8x35mm bolt (P/N 6506269AA) and a M8x85mm bolt are both used. Putting a long bolt in a short hole will crack the block; a short bolt in a long hole will not seal.

As you remove each bolt, get a piece of cardboard and sketch a simple outline of the water pump. Punch each bolt through the cardboard in its corresponding location. This guarantees every bolt goes back into its original hole.

Step 5: Clean the Engine Block Mating Surface

This is the second most critical step for a leak-free job. The mating surface on the engine block must be perfectly clean. Use a plastic scraper (never metal, which can gouge the aluminum timing cover) to remove all old gasket material. Gently use a Scotch-Brite pad and brake cleaner to ensure the surface is bare, dry, and free of all oil and coolant.

Step 6: The “Gasket vs. RTV” Debate (The Truth)

You will find many conflicting opinions on whether to use RTV silicone sealant on the new gasket. Here is the definitive, professional answer:

DO NOT USE RTV GASKET MAKER on the 5.7 Hemi water pump gasket.

Modern Mopar-style gaskets (multi-layer steel with a rubber inlay) are designed to be installed DRY onto a perfectly clean surface. Applying RTV silicone acts as a lubricant, which can cause the rubber part of the gasket to “squeeze out” or tear when torqued, creating a leak. This is a very common mistake.

Step 7: Install New Pump & The Correct Tightening Sequence

A “torque sequence” is essential to apply pressure evenly, preventing the pump housing from warping or pinching the gasket. Do not simply tighten the bolts in a circle. The correct method is a criss-cross or star pattern that starts from the center bolts and works outward.

5.7 Hemi Water Pump Bolt Tightening Sequence

Rationale: A visual diagram is the best way to communicate the “criss-cross” pattern. This description can be given to a graphic designer.

Description: A simple line-art diagram of the 5.7 Hemi water pump. The 10+ bolt holes are clearly visible. The bolts are numbered 1, 2, 3, etc., showing a tightening pattern that starts in the center of the pump, then alternates, moving from top-to-bottom and side-to-side in a “star” pattern, ending with the outermost bolts. This illustrates the principle of working from the center-out.

Use the following 3-step torque procedure:

- Hand-Snug: Install the new gasket (dry) and pump. Thread all M8 bolts and M6 nuts by hand (using your cardboard template) until they are just snug. This ensures no cross-threading.

- First Pass (Criss-Cross): Using your torque wrench and the criss-cross pattern, torque all M8 bolts to 10 ft-lbs and all M6 nuts to ~5 ft-lbs. This seats the gasket evenly.

- Final Pass (Criss-Cross): Following the same pattern, make the final pass. Torque all M8 bolts to 21 ft-lbs (28 N·m) and all M6 nuts to 9 ft-lbs (12 N·m).

Step 8: Re-fill, “Burp” the System, and Check for Leaks

Re-install all hoses, the idler pulley, and the belt tensioner. Re-install the serpentine belt. Re-install the fan clutch (remember: counter-clockwise to tighten).

Now, you must “burp” the cooling system to remove all air pockets, which can cause overheating.

- Attach a spill-free coolant funnel to the radiator cap opening.

- Fill the funnel (and radiator) with a 50/50 mix of the correct coolant (see section below) and distilled water.

- Start the engine and turn the vehicle’s heater to the highest temperature and fan setting.

- Let the engine idle. As it warms up, the thermostat will open, and you will see the coolant level in the funnel drop dramatically as it fills the engine block.

- Continue to add coolant to the funnel, keeping it about 1/3 full. Let the engine run until all bubbles have stopped surfacing in the funnel. This may take 15-20 minutes.

- Once burped, stop the engine, let it cool, and then top off the coolant reservoir.

The Hemi Owner’s Technical Guide (Bolts & Coolant)

Understanding these two technical details is just as important as the torque specs.

5.7 Hemi Water Pump Bolt Details: TTY, Size, and Part Numbers

Are 5.7 Hemi Water Pump Bolts TTY (Torque-to-Yield)?

No. The 5.7 Hemi water pump bolts are NOT Torque-to-Yield (TTY) bolts.

This conclusion is drawn from the torque specification itself. TTY bolts are defined by a torque-to-angle specification, such as “25 ft-lbs plus 90 degrees”. This procedure is designed to stretch the bolt past its elastic limit for a specific clamping force. The 5.7 Hemi cylinder head bolts and connecting rod bolts are TTY.

The water pump bolt specification is a simple, single-value torque: “21 ft-lbs”. Because there is no angle specification, the bolts are not designed to stretch and are reusable, provided they are clean and the threads are in good condition.

What is the 5.7 Hemi Water Pump Bolt Size?

The primary bolts used are M8 (Metric 8mm) with a 1.25 thread pitch. As noted in the “cardboard trick,” they come in various lengths, including M8x35mm and M8x85mm.

- Common Mopar Part Number (M8x35mm):

6506269AA

Critical Warning: 5.7 Hemi Coolant Type (HOAT vs. OAT)

Using the wrong coolant is the #1 way to destroy your new water pump and the entire cooling system. Mopar switched coolant chemistries in 2013, and the two types are NOT compatible.

The Great Divide: The 2013 Model Year

- ~2003-2012 Hemi Engines: Use HOAT (Hybrid Organic Acid Technology).

- Mopar Spec: MS-9769

- Color: Typically orange or red.

- Service Life: 5 Years / 100,000 Miles.

- ~2013-Present Hemi Engines: Use OAT (Organic Acid Technology).

- Mopar Spec: MS.90032 (or MS-12106).

- Color: Officially purple, but it famously looks dark red or orange in the reservoir, causing massive confusion.

- Service Life: 10 Years / 150,000 Miles.

THE ULTIMATE WARNING: DO NOT MIX AND DO NOT TRUST THE COLOR!

Because both HOAT and OAT coolants can appear red or orange in the truck, owners and even repair shops frequently mix them.

Mixing HOAT and OAT causes a catastrophic chemical reaction. The coolant will turn into a thick, viscous “gel”. This gel will clog the water pump, radiator, and heater core, starving the engine of coolant and causing total cooling system failure. This is one of the most catastrophic (and avoidable) common 5.7 Hemi engine problems a new owner can make.

The only safe way to know what coolant to use is to check your owner’s manual or the Mopar specification on the bottle. When in doubt, perform a complete system flush and refill with the correct type.

Table: Mopar HOAT vs. OAT Coolant Guide

Rationale: This simple comparison table clarifies the most dangerous and confusing part of the cooling system job. It visually separates the two incompatible chemistries by their specification and model years.

| Feature | HOAT (Hybrid) | OAT (Organic) |

| Model Years | ~2003-2012 | ~2013-Present |

| Mopar Spec | MS-9769 | MS.90032 (or MS-12106) |

| Color | Orange / Red | Purple (Looks Red/Orange) |

| Service Life | 5 Year / 100k Mile | 10 Year / 150k Mile |

| Compatibility | DO NOT MIX WITH OAT | DO NOT MIX WITH HOA |

Frequently Asked Questions (FAQ)

Q: What is the 5.7 Hemi thermostat housing bolt torque spec?

A: The 5.7 Hemi thermostat housing bolts torque to 21 ft-lbs (28 N·m).2 It is highly recommended to replace the thermostat (which is often housed in the water pump or a separate housing) at the same time as the pump.

Q: How much does a 5.7 Hemi water pump replacement cost?

A: A DIY replacement typically costs between $150 and $400 for high-quality parts (new pump, coolant, thermostat). Having the job done professionally can range from $300 to $900, depending on local labor rates.

Q: What is the torque spec for the 5.7L “Eagle” Hemi water pump?

A: The “Eagle” Hemi (the 2009+ 5.7L VVT engine) uses the same torque specifications as the earlier 5.7L. The water pump M8 bolts torque to 21 ft-lbs (28 N·m), and the M6 nuts torque to 9 ft-lbs (12 N·m).

Q: Do I need RTV sealant with the 5.7 Hemi water pump gasket?

A: No. Do not use RTV or any other sealant on a new OEM-style metal/rubber gasket. It is designed to be installed dry. Adding RTV can cause the seal to fail by allowing it to squeeze out under torque.

Conclusion: Your Leak-Free Finish

A successful, leak-free 5.7 Hemi water pump replacement is a job of precision, not just force. It comes down to three non-negotiable rules:

- The Right Torque: Use the correct, distinct torque values. 21 ft-lbs (28 N·m) for the M8 bolts and 9 ft-lbs (12 N·m) for the nuts.

- The Right Pattern: Use a 3-step, criss-cross torque sequence (snug, then 10 ft-lbs, then 21 ft-lbs) to seat the gasket evenly.

- The Right Prep: Use a perfectly clean, dry mating surface with a new gasket and no RTV sealant.

Don’t guess with your wrench. The final, critical step is to use a calibrated tool. If you are new to this, see our complete guide on how to use a torque wrench. By following these technical specifications, you can be confident in a repair that will last. For a full list of other Gen III Hemi torque specs, refer to a comprehensive chart from a reliable source like(https://www.briantooleyracing.com/media/pdfs/technical/BTR_GEN_III_HEMI_TORQUE_SPECS_001.pdf).