Cummins Isx Oil Pressure Relief Valve Location: Find It Here!

The oil pressure relief valve in a Cummins ISX engine is located at the oil pump outlet, and its purpose is to open when engine oil pressure reaches a certain value. A problem with this valve can cause damage to the engine oil filter and the engine itself.

The oil pressure relief valve in a Cummins ISX engine plays a critical role in maintaining the proper oil pressure within the engine. This valve is designed to open when the oil pressure reaches a certain level, ensuring that the engine is adequately lubricated.

However, if there is a problem with the relief valve, it can lead to damage to the engine oil filter and the engine itself. Therefore, it is essential for Cummins ISX owners and technicians to know the location of the oil pressure relief valve to address any potential issues. We will discuss the precise location of the relief valve and its importance in maintaining the engine’s health.

Understanding The Oil Pressure Relief Valve

|

The oil pressure relief valve is a critical component in the engine’s lubrication system. Located at the oil pump outlet, its primary function is to open and release excessive oil pressure when it reaches a certain value. This helps protect the engine and the oil filter from damage. A malfunctioning pressure relief valve can have serious consequences for the engine. It can lead to low oil pressure, which can cause engine damage and reduce performance. On the other hand, if the valve fails to open when the pressure gets too high, it can lead to catastrophic engine failure. For the engine to operate at its best, it is crucial that the oil pressure relief valve functions correctly. Regular inspection and maintenance of the valve are essential to ensure optimal engine performance and longevity. Any signs of a faulty relief valve, such as low or high oil pressure, should be addressed immediately to prevent further damage. |

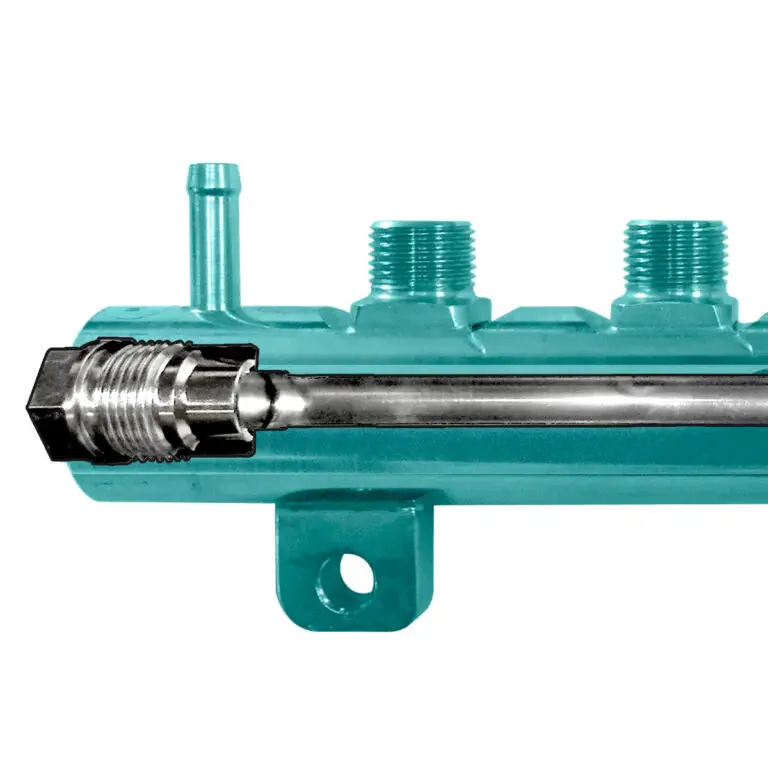

Credit: www.woodlineparts.com

Signs Of A Faulty Oil Pressure Relief Valve

| Signs of a Faulty Oil Pressure Relief Valve: |

| – System Cannot Reach Pressure: If your system isn’t reaching pressure, this could be a sign of pressure relief valve failure. |

| – System is Over Maximum Pressure: Excessive pressure in the system may indicate a faulty oil pressure relief valve. |

| – Pressure Relief Valve is Leaking or Has No Pressure: A leaking or malfunctioning pressure relief valve can cause a loss of pressure and potential damage to the engine. |

The oil pressure relief valve in a Cummins ISX engine is located at the oil pump outlet, just below the turbo where the filter housing is. Its purpose is to open when engine oil pressure reaches a certain value, allowing oil to bypass the filter and relieve excessive pressure. If the relief valve fails or becomes faulty, it can lead to various issues. For instance, if the system cannot reach the required pressure, it may indicate a problem with the relief valve. On the other hand, if the system is experiencing over maximum pressure, it could also suggest a faulty relief valve. Additionally, a relief valve that is leaking or has no pressure can result in low oil pressure and potential engine damage. It is essential to address any signs of a faulty oil pressure relief valve to maintain the proper functioning of the engine.

Common Issues With The Oil Pressure Relief Valve

To address the location of the oil pressure relief valve, it can be found at the oil pump outlet, just below the turbo where the filter housing is. The purpose of this valve is to open when the engine oil pressure reaches a specific value, preventing damage to the engine oil filter and the engine itself. If the oil pressure relief valve is faulty, it can cause various issues.

Scratched Bore

If the bore of the relief valve is scratched, it can result in the regulator sticking. This, in turn, can cause low or high oil pressure, making it the primary reason for such issues. It is essential to ensure that the relief valve and its bore are in good condition to maintain proper oil pressure in the engine.

Knowing how to identify a faulty oil pressure relief valve is crucial. Signs of a bad valve include the system failing to reach pressure, the system exceeding maximum pressure, or the valve leaking or lacking pressure.

Locating The Oil Pressure Relief Valve

The Cummins ISX oil pressure relief valve is located at the oil pump outlet. It opens when engine oil pressure reaches a certain value and a malfunction in the valve can cause damage to the engine oil filter and the engine itself.

| Location of the Oil Pressure Relief Valve: | The oil pressure relief valve is located at the oil pump outlet, just below the turbo where the filter housing is. |

| Purpose of the Oil Pressure Relief Valve: | The purpose of the oil pressure relief valve is to open when engine oil pressure reaches a certain value. Its function is to prevent damage to the engine oil filter and the engine itself. |

| Signs of a Bad Oil Pressure Relief Valve: | If your system isn’t reaching pressure, or if the system is over maximum pressure, it could be a sign of pressure relief valve failure. Another sign is if the relief valve is leaking or has no pressure. |

| Causes of Low Oil Pressure in ISX Cummins: | One possible cause of low oil pressure in ISX Cummins is a scratched bore in the regulator, which can cause it to stick. This is the most common reason for low oil pressure. |

Troubleshooting Low Oil Pressure In Cummins Isx

Factors that cause low oil pressure in Cummins ISX engines can vary, and it’s important to understand them in order to diagnose and resolve the issue effectively. One common factor is a faulty oil pressure relief valve, which is located at the oil pump outlet. This valve is designed to open when engine oil pressure reaches a certain value, and if it fails to function properly, it can cause damage to the engine oil filter and the engine itself.

Another potential cause of low oil pressure is scratches in the valve bore, which can result in the regulator sticking and disrupting the oil pressure. This is often considered the number one reason for low oil pressure in Cummins ISX engines.

It is crucial to note that the minimum oil pressure for a Cummins ISX engine can vary depending on the specific model and operating conditions. It is recommended to refer to the engine’s manual or consult a professional for the accurate minimum oil pressure specifications.

If you suspect a problem with the oil pressure relief valve, symptoms such as the system failing to reach pressure, pressure relief valve leakage, or excessive pressure should be monitored. If any of these issues occur, it may indicate a faulty valve that needs to be addressed.

Frequently Asked Questions Of Cummins Isx Oil Pressure Relief Valve Location

Where Is Oil Pressure Relief Valve Located?

The oil pressure relief valve is located at the oil pump outlet. Its purpose is to open when engine oil pressure reaches a certain value. A problem with this valve can cause damage to the engine oil filter and the engine itself.

How Do I Know If My Oil Pressure Relief Valve Is Bad?

To determine if your oil pressure relief valve is bad, watch out for these signs: 1) Your system cannot reach the desired pressure. 2) The system exceeds maximum pressure. 3) The relief valve leaks or shows no pressure.

What Causes Low Oil Pressure In Isx Cummins?

The pressure relief valve located at the oil pump outlet can cause low oil pressure in ISX Cummins. If the valve is damaged or stuck, it can lead to low or high oil pressure. It is important to address this issue as it can cause damage to the engine oil filter and the engine itself.

What Is Normal Oil Pressure On A Cummins Isx15?

The normal oil pressure on a Cummins ISX15 can vary, but it typically ranges from 30 to 60 psi. The oil pressure should be consistent and within this range for the engine to operate properly. It is important to monitor and maintain the oil pressure to prevent engine damage.

Conclusion

To locate the oil pressure relief valve on your Cummins ISX engine, you can find it at the oil pump outlet. This valve serves the important purpose of opening when the engine oil pressure reaches a certain level, preventing damage to both the oil filter and the engine itself.

If you suspect a problem with the relief valve, it is crucial to address it promptly to ensure the proper functioning of your engine.