Cummins X15 Egr Valve Location: Unveiling the Hidden Spot

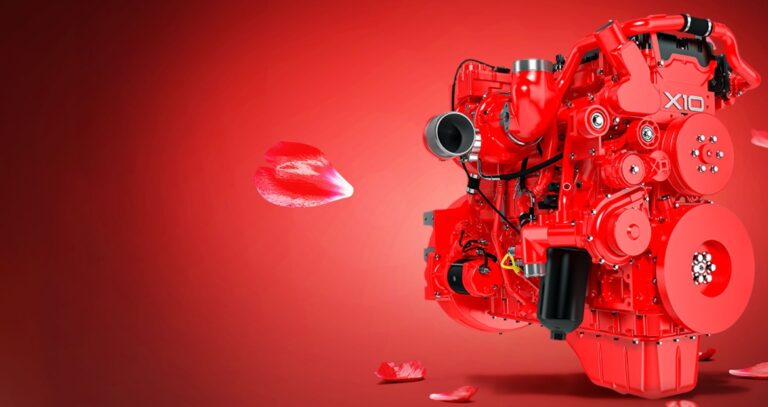

The EGR valve on the Cummins X15 engine is located on the passenger side of the engine towards the front, approximately at the same height as the turbo. This valve is hooked on the front side of the EGR cooler.

The Cummins X15 engine is widely used in the trucking industry for its power and performance. One important component of this engine is the EGR valve, which plays a crucial role in reducing emissions and improving fuel efficiency. Knowing the exact location of the EGR valve is essential for maintenance and troubleshooting purposes.

We will provide a concise answer to the question: “Where is the EGR valve on Cummins X15? ” Additionally, we will discuss the symptoms of a faulty EGR valve and highlight the importance of regular maintenance for the overall performance of the engine. So, let’s dive in and explore the EGR valve location and its significance in the Cummins X15 engine.

Credit: www.yumpu.com

Where Is The Egr Valve On Cummins X15?

Where is the EGR valve on Cummins X15? The EGR valve on Cummins X15 can be found on the front side of the EGR cooler, specifically on the passenger side of the engine. It is located near the front of the engine and is at the same height as the turbo. The EGR valve plays a crucial role in the exhaust gas recirculation system by controlling the flow of exhaust gases back into the engine. It is important to regularly maintain and inspect the EGR valve to ensure its proper functioning. Failure to do so can result in various issues such as rough idle, excessive smoke, increased fuel consumption, decreased engine performance, and the activation of the check engine light. If you suspect any problems with the EGR valve, it is recommended to consult a professional for diagnosis and potential repairs.

How To Clean The Egr Cooler On Cummins X15?

A Step-By-Step Guide to Cleaning the EGR Cooler on a Cummins X15 Engine

- Socket set

- Wrench

- Ratchet

- Engine coolant

- EGR cleaner

- Protective gloves

Locate the battery and remove the negative cable to disconnect the battery.

Locate the coolant drain plug or petcock and open it to drain the coolant from the system.

Remove any electrical connectors, hoses, and bolts securing the EGR cooler. Carefully lift the EGR cooler out of the engine compartment.

Using the EGR cleaner, thoroughly clean all surfaces of the EGR cooler. Pay special attention to any areas with built-up carbon deposits.

Using a multimeter, test the electrical connections on the EGR cooler for proper functionality. Ensure that there are no leaks or blockages in the cooler.

Carefully place the EGR cooler back into the engine compartment and reattach all electrical connectors, hoses, and bolts. Reconnect the battery and refill the coolant.

Symptoms Of A Bad Egr Valve On Cummins X15

Having a bad EGR valve on your Cummins X15 engine can lead to a range of symptoms:

Rough idle: A rough idling engine is a common sign of a faulty EGR valve. It can result in an uneven and unstable engine speed.

Excessive smoke: If you notice excessive smoke coming from the exhaust, it could be due to a malfunctioning EGR valve. This can be caused by an improper mixture of fuel and air.

Increased fuel consumption: A faulty EGR valve can cause the engine to burn more fuel than necessary. This can lead to decreased fuel efficiency and higher fuel costs.

Decreased engine performance: An EGR valve that is not functioning properly can affect the overall performance of the engine. It may result in sluggish acceleration and reduced power.

Check engine light: The check engine light may illuminate on the dashboard if there is a problem with the EGR valve. This is the engine’s way of alerting you to a potential issue.

Frequently Asked Questions On Cummins X15 Egr Valve Location

How Do You Clean The Egr Valve On A Cummins Isx 15?

To clean the EGR valve on a Cummins ISX 15: 1. Gather necessary tools and supplies. 2. Disconnect the battery. 3. Drain the coolant. 4. Remove the EGR cooler. 5. Clean the EGR cooler. 6. Test the EGR cooler. 7. Reinstall the EGR cooler.

The EGR valve is located on the passenger’s side of the engine towards the front, hooked on the front side of the EGR cooler. Common symptoms of a bad EGR valve include rough idle, excessive smoke, increased fuel consumption, decreased engine performance, and a check engine light.

The EGR system was introduced on the Cummins ISX in a particular model year. For more information, refer to the Cummins ISX Engine Specs, Reviews & Problems guide.

Where Is The Egr Valve On Cummins Isx?

The EGR valve on the Cummins ISX is located on the passenger side of the engine towards the front. It is hooked on the front side of the EGR cooler and is about the same height as the turbo.

What Are The Symptoms Of A Bad Egr Valve On An Isx Cummins?

Symptoms of a bad EGR valve on an ISX Cummins include rough idle, excessive smoke, increased fuel consumption, decreased engine performance, and a check engine light.

What Year Did The Egr System Come Out On The Cummins Isx?

The EGR system came out on the Cummins ISX in 2002.

Conclusion

The EGR valve on a Cummins X15 engine is located on the passengers side of the engine, towards the front. It is hooked on the front side of the EGR cooler, about the same height as the turbo. Symptoms of a faulty EGR valve can include rough idle, excessive smoke, increased fuel consumption, decreased engine performance, and a check engine light.

To clean the EGR cooler, follow a step-by-step guide that involves gathering necessary tools, disconnecting the battery, draining the coolant, removing and cleaning the EGR cooler, testing it, and finally reinstalling it.