Where Is My Fuel Filter Location? A Complete Guide for Cars & Trucks

The Unsung Hero of Your Engine: What is a Fuel Filter?

Deep within the complex network of lines and components that make up your vehicle’s fuel system lies a small, often overlooked part: the fuel filter. While it may not have the high-tech allure of a turbocharger or the raw power of a V8 engine, the fuel filter performs one of the most critical functions in any modern car or truck. It acts as the gatekeeper, the vigilant guardian that ensures only clean, pure fuel reaches the heart of your engine.

Its job is to screen out dirt, rust particles, sediment, and other contaminants that can find their way into your fuel. This debris can originate from the underground storage tanks at a gas station or even from the inside of your vehicle’s own fuel tank over time. Without this crucial filtration, these abrasive particles would wreak havoc on the entire system.

Why Clean Fuel is Non-Negotiable for Modern Engines

The transition from older, carbureted engines to modern Electronic Fuel Injection (EFI) systems has elevated the fuel filter from a helpful component to a mission-critical one. Carbureted engines used relatively large jets to deliver fuel and could tolerate larger contaminants—around 30 to 40 microns—without immediate issues.

Modern fuel injectors, however, are marvels of precision engineering. They atomize fuel through microscopic openings to create a perfect mist for combustion. These openings are incredibly sensitive and can be easily clogged by particles as small as 2 to 10 microns. A clogged injector leads to poor performance, misfires, and reduced fuel economy. Therefore, the fine filtration provided by a quality fuel filter is absolutely essential for the health and efficiency of any modern truck engine.

Where is My Fuel Filter?

A Visual Guide to Locations, Symptoms, and Costs

Common Fuel Filter Locations

Finding your fuel filter isn’t always easy, as its location varies by manufacturer and model year. Modern vehicles, in particular, have consolidated parts, making the “in-tank” design increasingly common.

The 3 Primary Location Types

Depending on your vehicle, you’ll most likely find the filter in one of these three areas. The location directly impacts the difficulty and cost of replacement.

1. Engine Bay

Easiest to access. Often found on older vehicles or some diesel engines. Look on the firewall or near the fuel rail, connected directly to the fuel lines.

2. Frame Rail (Under Vehicle)

Very common on trucks, SUVs, and many cars from the 90s-2000s. You’ll need to safely jack up the car to find it secured to the frame rail, usually near the rear wheel.

3. In-Tank (Fuel Pump Module)

The standard for most modern cars. The filter is integrated into the fuel pump assembly inside the fuel tank. Often considered a “lifetime” filter, it’s only replaced when the pump fails.

Is Your Filter Clogged? Top 5 Symptoms

A clogged fuel filter starves your engine of fuel, leading to noticeable performance issues. These symptoms can also indicate other fuel system problems, such as a failing fuel pump, so proper diagnosis is key.

Average Replacement Cost (USD)

Costs vary dramatically based on the filter’s location. In-tank filters are expensive because the entire fuel pump module is typically replaced, which is a labor-intensive job.

DIY Difficulty Rating

While changing an engine bay filter is simple, frame rail filters require working under the car with pressurized fuel lines (a fire risk). In-tank filters require dropping the entire fuel tank.

-

Engine Bay:

⭐(Easy)

-

Frame Rail:

⭐⭐⭐(Medium – Safety Risk)

-

In-Tank:

⭐⭐⭐⭐⭐(Hard – Professional Advised)

Key Takeaways & Further Reading

Always check your owner’s manual first! It is the definitive source for your vehicle’s service intervals and filter type. For inline filters (engine bay or frame rail), a typical replacement interval is every 20,000 to 40,000 miles

.Internal Resources:

How a Fuel Filter Protects Your Fuel Pump and Injectors

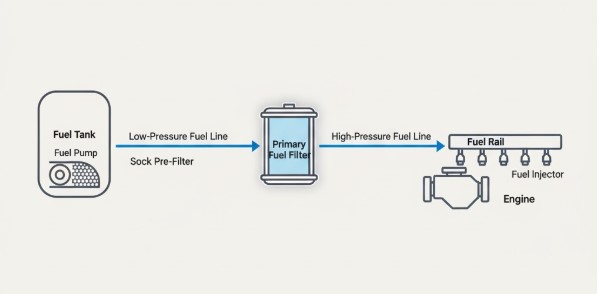

The fuel filter is strategically placed along the fuel line, always situated between the fuel tank and the engine. As the fuel pump draws gasoline or diesel from the tank, it pushes it through the filter’s media, which traps the harmful contaminants. This process protects two of the most expensive and sensitive parts of the system:

- The Fuel Pump: While some filters are placed after the pump, many systems use a pre-filter or “sock” inside the tank to catch large debris before it can enter and damage the pump’s internal mechanisms.

- The Fuel Injectors: The primary filter is the last line of defense for the injectors, ensuring the fuel that reaches them is free of particles that could cause blockages and lead to costly repairs.

Simplified Fuel System Schematic

Create a clean, simple line-art diagram illustrating the basic flow of a modern fuel system. The style should be clear and easy to understand, not a complex technical blueprint.

- Start with a simple icon for the Fuel Tank on the left.

- Inside the tank, show a basic Fuel Pump icon with a mesh “Sock” Pre-Filter at its base.

- An arrowed line labeled “Low-Pressure Fuel Line” exits the tank and leads to a highlighted, canister-shaped icon labeled “Primary Fuel Filter.” This filter should be the visual focus.

- From the primary filter, an arrowed line labeled “High-Pressure Fuel Line” leads to a long bar icon labeled “Fuel Rail.”

- Branching down from the fuel rail are several smaller icons labeled “Fuel Injectors,” pointing toward a simplified outline of an “Engine.”

- Arrows should clearly indicate the direction of fuel flow from left to right.

A Look Inside: The Different Types of Fuel Filters

Not all fuel filters are created equal. They come in various shapes, sizes, and designs tailored to specific vehicles and fuel types. Understanding these differences is the first step in correctly identifying and servicing the filter in your truck.

Inline vs. In-Tank Filters: The Accessibility Trade-Off

The most significant distinction for any vehicle owner is whether the filter is an easily accessible inline unit or a more complex in-tank design. This difference reflects a fundamental shift in automotive design philosophy over the years.

- Inline Fuel Filters: These are the traditional, standalone filters that most DIY mechanics are familiar with. They are self-contained plastic or metal canisters installed somewhere along the fuel line, typically under the vehicle or in the engine bay. Their primary advantage is ease of access, making replacement a straightforward maintenance task with a relatively low cost.

- In-Tank Fuel Filters: Increasingly common in modern vehicles, these filters are located inside the fuel tank itself. They are often integrated directly with the fuel pump assembly, sometimes as a simple mesh “sock” that serves as a pre-filter, or as a more substantial, non-serviceable component of the entire fuel pump module. While this design offers superior protection for the fuel pump by filtering fuel at the source, it comes at a significant cost. Replacement is a complex and expensive job that usually requires removing the fuel tank.

This evolution from accessible inline filters to integrated in-tank units highlights a manufacturer design choice: prioritizing the longevity of the expensive fuel pump assembly over the simplicity and low cost of routine filter maintenance for the vehicle owner.

Cartridge and Spin-On Filters: Common Designs for Diesel and Heavy-Duty Use

While inline and in-tank describe the location, other terms refer to the filter’s physical design, particularly in diesel and heavy-duty trucks.

- Cartridge Filters: This design consists of a permanent housing (often with a drain for water) and a replaceable filter element inside. To service it, one unscrews the housing, replaces the paper-like cartridge, and reassembles it. This type is very common on diesel engines.

- Spin-On Filters: Instantly recognizable by their resemblance to an oil filter, these are self-contained metal canisters that thread onto a mounting base. They offer a large filtration capacity and are popular in heavy-duty and diesel applications for their durability and simple replacement process.

Understanding Filtration: Micron Ratings and Filter Media

The effectiveness of a fuel filter is determined by its internal construction.

- Filter Media: The material that does the actual filtering is most often a specially treated, pleated paper element designed to maximize surface area. High-performance filters may use synthetic fibers like nylon for improved flow and durability, while some older or reusable filters use a metal mesh.

- Micron Rating ($ \mu m $): This number indicates the size of the particles the filter is designed to capture, measured in microns (one-millionth of a meter). A lower micron rating means finer filtration. For example, an older carbureted engine might use a 30-micron filter, while a modern EFI system requires a 10-micron or even 2-micron filter to protect its sensitive injectors. While finer filtration is better, it can also cause the filter to clog more quickly, especially if fuel quality is poor.

The Main Event: Pinpointing Your Fuel Filter’s Location

Finding your fuel filter can range from a 30-second glance under the hood to a multi-hour project involving specialized tools. The location depends entirely on your vehicle’s make, model, year, and engine type. However, nearly all serviceable fuel filters can be found in one of four primary locations.

Location 1: Under the Hood (Engine Bay)

- Where to Look: This was once the standard location, especially for vehicles made before the 2000s. Scan the engine compartment, paying close attention to the firewall (the metal partition between the engine and the passenger cabin) and the inner fender wells. It’s often found near the brake master cylinder or battery.

- What it Looks Like: A small cylindrical canister, typically 3 to 8 inches long, made of metal or black plastic. It will have a fuel line connected to each end.

- Vehicles: Common on older cars and many trucks and SUVs.

- Pros & Cons: This is by far the most accessible location, making replacement a quick and easy DIY job. The main drawback is the filter’s exposure to high under-hood temperatures.

Location 2: Under the Vehicle (Frame Rail)

- Where to Look: This is arguably the most common location for modern trucks, SUVs, and many cars. The filter is mounted to the vehicle’s chassis frame, usually on the driver’s side, running parallel to the fuel lines between the tank and the engine. Accessing it requires safely lifting and supporting the vehicle on jack stands.

- What it Looks Like: A metal or plastic canister held in place by a mounting bracket or clips. It’s often partially obscured by a small plastic shield for protection.

- Vehicles: The predominant location for many modern gasoline and diesel trucks, including popular models from Ford, GM, and Ram.

- Pros & Cons: This placement offers a good balance, protecting the filter from engine heat while keeping it out of the crowded engine bay. However, it is highly vulnerable to road salt, moisture, and debris, which can cause severe corrosion on the fittings and make removal extremely difficult.

Location 3: Inside the Fuel Tank (As Part of the Fuel Pump Module)

- Where to Look: This design is non-serviceable in the traditional sense. The filter is an integral part of the fuel pump module, which is submerged inside the fuel tank. Access is typically gained by either dropping the entire fuel tank from under the vehicle or, on some cars and SUVs, through an access panel located under the rear seat cushions or trunk carpet.

- What it Looks Like: You will not see a standalone filter. The filtration element is a component within the larger plastic and metal fuel pump assembly.

- Vehicles: Increasingly prevalent in most passenger vehicles manufactured after the mid-2000s.

- Pros & Cons: This location provides maximum protection for the fuel pump itself. The major downside is the extreme difficulty and high cost of replacement. It is not considered a routine maintenance item and is typically only replaced when the entire fuel pump fails.

The following table provides a quick comparison of these common locations.

| Location | Accessibility / DIY Difficulty | Typical Replacement Cost | Common On… | Pros / Cons |

| Engine Bay | Easy / Low | Low ($) | Pre-2000s vehicles, some trucks | Pro: Very easy to access and replace. Con: Exposed to high engine heat. |

| Frame Rail | Moderate / Medium | Medium ($$) | Most modern trucks, SUVs, and cars | Pro: Good balance of protection and access. Con: Vulnerable to rust/damage, requires lifting vehicle. |

| In-Tank | Hard / High | High ($$$$) | Most post-2005 vehicles | Pro: Protects the fuel pump. Con: Very difficult and expensive to replace; often requires tank removal. |

| Rear of Vehicle | Moderate / Medium | Medium ($$) | Some specific models | Pro: Away from engine heat. Con: Vulnerable to road debris, requires lifting vehicle. |

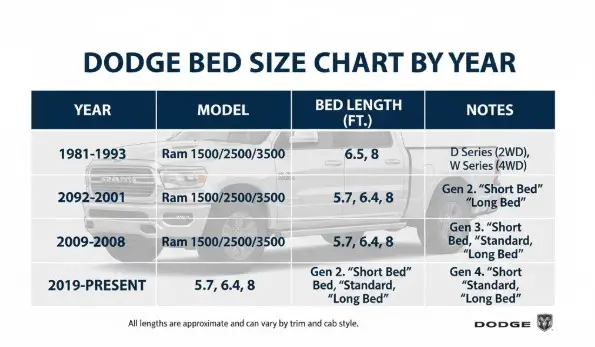

Quick Reference Guide: Fuel Filter Location on Popular Trucks

While the owner’s manual is always the most accurate source, this guide provides the typical fuel filter locations for some of the most popular trucks on the road. Note the significant differences between gasoline and diesel models, which often have more complex filtration systems.

The number and type of filters on a truck are directly related to its fuel type and intended workload. Light-duty gasoline trucks have trended toward simpler, single-filter systems designed for convenience. In contrast, heavy-duty diesel trucks consistently use robust, dual-filter systems to handle the higher risk of fuel contamination (especially water) and to protect their extremely high-pressure and costly injection components. For diesel owners, reliability and thorough filtration take clear priority over a “maintenance-free” design.

| Truck Model & Year Range | Engine Type | Typical Fuel Filter Location(s) & Notes |

| Chevy Silverado 1500 (1999-2006) | Gasoline | Driver’s side frame rail, near the tank. |

| Chevy Silverado 2500/3500 (Modern) | Duramax Diesel | Primary filter/water separator is typically under the hood on the driver’s side, often a visible spin-on or cartridge style. |

| Ford F-150 (1997-2003) | Gasoline | Driver’s side frame rail. |

| Ford F-150 (2004+) | Gasoline | Inside the fuel tank, integrated with the fuel pump module. Generally considered non-serviceable. |

| Ford F-250/F-350 (Modern) | Power Stroke Diesel | Dual filter system: A primary filter/water separator on the frame rail and a secondary filter under the hood. |

| Ram 1500 (Modern) | Gasoline (Hemi) | Inside the fuel tank as part of the non-serviceable fuel pump module. |

| Ram 1500 (Modern) | 3.0L EcoDiesel | A single, serviceable cartridge-style filter located in an accessible spot, often on the frame rail or near the rear of the engine. |

| Ram 2500/3500 (Modern) | Cummins Diesel | Dual filter system: One filter is located under the hood (front), and a second filter/water separator is located under the truck, near the fuel tank (rear). |

Is Your Fuel Filter Clogged? 8 Telltale Symptoms to Watch For

A fuel filter doesn’t fail suddenly; it clogs gradually over thousands of miles. As the flow of fuel becomes more restricted, your truck will start giving you clear warning signs that it’s being starved of fuel. Ignoring these symptoms can lead to damage to your fuel pump and leave you stranded.

Performance Issues: Sluggish Acceleration, Hesitation, and Power Loss

When you demand more power from your engine, like when accelerating, towing, or climbing a hill, it needs more fuel. A clogged filter can’t keep up with this demand.

- Sluggish Acceleration and Hesitation: This is the most common symptom. You press the gas pedal, and the truck stutters, jerks, or feels unresponsive before it starts to pick up speed.

- Engine Misfires: The restricted fuel flow creates a “lean” air-fuel mixture (too much air, not enough fuel), which can cause the engine to misfire, especially under load.

- Poor Gas Mileage: Your engine has to work much harder to pull fuel through the clogged filter, causing it to burn more fuel than usual to maintain performance.

Starting and Idling Problems

Even at low speeds or at a standstill, a clogged filter can cause noticeable issues.

- Difficulty Starting: The engine may crank for an extended period before it finally starts, or it may not start at all. This is because the fuel pump can’t build enough pressure in the lines to initiate combustion.

- Rough Idling: A restricted and inconsistent fuel supply can cause the engine to vibrate, shake, or sound rough while idling at a stoplight.

- Engine Stalling: In severe cases, the fuel restriction can be so bad that the engine stalls completely, often at low speeds or when coming to a stop.

Audible and Visual Cues

Sometimes, your truck will give you direct audio or visual warnings.

- Loud Whining from the Fuel Pump: You may hear a distinct whining or humming noise coming from the area of the fuel tank. This is the sound of your electric fuel pump straining and working overtime to force fuel through the blockage. This is a serious warning sign that the pump itself is at risk of burning out.

- Check Engine Light: The fuel system is monitored by numerous sensors. A clogged filter can cause low fuel pressure, which will trigger a sensor and illuminate the Malfunction Indicator Lamp (MIL), more commonly known as the Check Engine Light, on your dashboard.

If you suspect a bad filter, a mechanic can confirm it by connecting a fuel pressure gauge. A healthy system will maintain steady pressure when the engine is revved, while a system with a clogged filter will show a significant drop in pressure under acceleration. Many of these issues overlap with the symptoms of a failing fuel pump, which is why addressing a clogged filter early is critical to prevent pump failure.

How Often Should You Change Your Fuel Filter?

There is no single answer to this question, as replacement intervals vary widely depending on the vehicle.

Manufacturer Recommendations vs. Real-World Conditions

Always start by consulting your owner’s manual. Manufacturer recommendations can range from every 20,000-30,000 miles for older vehicles to 60,000 miles or more for newer ones. Diesel fuel filters often have shorter service intervals, typically every 10,000 to 15,000 miles, due to the higher risk of water and microbial contamination.

However, these are baseline recommendations under ideal conditions. Several real-world factors can significantly shorten the life of your fuel filter:

- Fuel Quality: Frequently purchasing fuel from low-volume, rural, or questionable gas stations can introduce more sediment and water into your tank. When it comes to filter life, choosing the right fuel for your truck can make a significant difference.

- Driving Environment: If you regularly drive on dirt roads, through construction zones, or in dusty environments, your fuel system is exposed to more contaminants.

- Vehicle Age: An older truck is more likely to have accumulated rust and debris inside its fuel tank, which will be caught by the filter.

The Myth of the “Lifetime” Filter

Many modern trucks with in-tank filters are marketed as having a “lifetime” filter. This term can be dangerously misleading for owners who plan to keep their vehicles for the long haul. “Lifetime” in this context often refers to the expected warranty period or the first 100,000 miles of the vehicle’s life, not eternity.

These filters can and do clog over time. The critical difference is that their failure is not a simple maintenance event. Instead, the fuel pump is forced to strain against the increasing restriction until it eventually fails, often leaving the driver stranded with a no-start condition. The subsequent repair involves replacing the entire expensive fuel pump module. For owners of high-mileage trucks, proactively replacing an in-tank pump and filter assembly around the 100,000-120,000 mile mark can be a wise investment to prevent a much more inconvenient and costly roadside failure.

Frequently Asked Questions (FAQs)

Can you clean a fuel filter?

For the vast majority of modern vehicles, the answer is no. Most fuel filters are sealed, disposable units containing paper or synthetic media that cannot be effectively cleaned. Attempting to flush them can damage the delicate filtration material and will not remove the microscopic particles trapped deep within the pleats. While some very old or specialized systems use a reusable metal mesh filter, these are extremely rare today.

What happens if you install a fuel filter backward?

Most fuel filters have an arrow printed or stamped on the housing to indicate the correct direction of fuel flow (always toward the engine). Installing a filter backward will cause a severe restriction, as the internal check valves and filter media are designed for one-way flow. This will immediately starve the engine of fuel, causing it to run poorly or not at all, and can potentially damage the internal structure of the new filter.

How much does it cost to replace a fuel filter?

The cost varies dramatically based on the filter’s location. For an external, frame-mounted filter, the part itself typically costs between $15 and $50. Professional installation at a repair shop will likely bring the total cost to between $100 and $215. For an in-tank filter, the cost is significantly higher because the entire fuel pump module is usually replaced. This is a major repair that can easily cost between $500 and $1,000 or more, depending on the truck.

Is replacing a fuel filter a DIY job?

This depends entirely on the filter’s location and your mechanical skill level. An engine bay or frame rail filter is a manageable task for a confident DIYer with the right safety precautions and tools. However, working with flammable fuel requires extreme care. An in-tank filter replacement is a complex and potentially dangerous job that involves dropping the fuel tank and is not recommended for most home mechanics.

What tools do I need to change a fuel filter?

Beyond standard wrenches and a drain pan, you may need specialized tools. For threaded fittings, a set of flare-nut wrenches is essential to avoid stripping the soft metal of the fuel line nuts. For the plastic quick-connect fittings found on most modern trucks, a specific fuel line disconnect tool is required to release the internal locking mechanism without breaking the fitting. Having these and other essential tools for your garage can make the difference between a successful repair and a costly mistake