John Deere Lawn Mower Blade Torque Specs

The torque specifications for a John Deere lawn mower blade depend on the type of mower and engine. Generally, blades should be torqued to between 16-20 foot pounds (ft-lbs). The nuts that secure the blade to the crankshaft should also be tightened to between 10-15 ft-lbs.

Additionally, if your mower has an anti-scalp wheel, it must be secured with a minimum of 15 ft-lbs of torque. It is important that all nuts are properly tightened and torqued according to manufacturer specs in order for safe operation of the machine.

John Deere lawn mowers are known for their quality and durability, so it’s important to ensure you adhere to the correct blade torque specs when replacing blades. The torque specifications vary depending on the type of blade being used, but generally range from 18-20 foot pounds. Be sure to consult your owner’s manual for more specific information before making any repairs or replacements.

With proper maintenance and care, your John Deere lawn mower will last a long time!

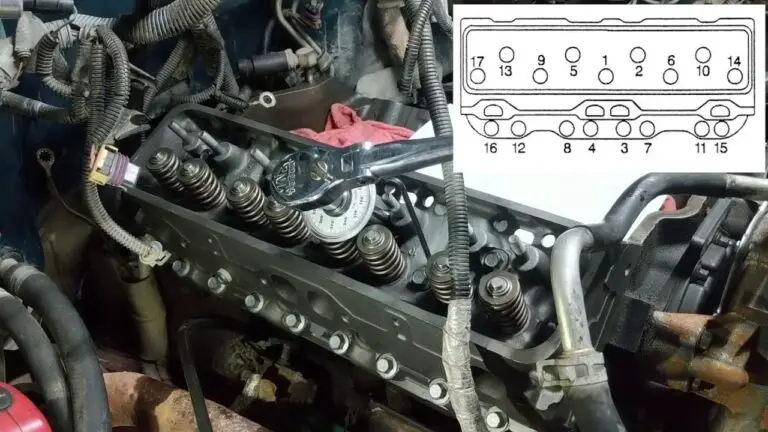

Blade bolt torque-go by the numbers!

What is the Torque for a Lawn Mower Blade?

The torque for a lawn mower blade is the amount of force needed to turn the blade around its axis. The size of this force can vary widely depending on the type and size of the mower, as well as other factors such as terrain and grass conditions. For example, large riding mowers will have higher torques than small push mowers due to their larger blades and more powerful engines.

Additionally, if you are cutting thick or wet grass then you may need even more torque in order to get through it. Generally speaking though, most walk-behind lawn mowers have an average torque rating between 8-10 foot-pounds while riding models usually require between 16-20 foot pounds (or higher). It’s important to note that these numbers should only be used as a guideline since there can be some variance between different manufacturers and models.

How Tight Should Mower Blade Bolts Be?

When it comes to mower blade bolts, it is important to ensure they are tightened correctly. It’s essential that the bolt be tight enough so that the blade won’t come loose and cause damage or injury, but not too tight as this can lead to cracked blades or other damage. The best way to determine how tight your mower blade bolts should be is by consulting your manufacturer’s manual for specific instructions; typically, it will recommend a torque setting for securing the bolt in place.

To achieve this optimal level of tension, use a torque wrench which allows you to accurately measure and apply force when tightening the nut on each side of the bolt. Additionally make sure that all nuts are securely fastened before operating your mower—loose bolts may cause serious accidents if they become dislodged while you’re cutting grass!

Do Mower Blades Need to Be Torqued?

Mower blades need to be torqued for optimal performance and efficiency. Proper torque ensures that the mower blade is securely fastened onto the mower deck, preventing it from becoming loose or slipping off during operation. Torque also helps ensure even cutting by balancing out any imbalance in the blade’s weight distribution.

Additionally, proper torque keeps your engine running smoothly and efficiently since it reduces vibration caused by imbalanced blades. To properly torque your mower blade, you will need an adjustable wrench and a torque wrench calibrated to the manufacturer’s specifications. First, make sure that all existing bolts are tightened before adding any additional ones; this helps balance out any irregularities in weight distribution.

Then, use the wrench to tighten each bolt until it reaches its specified level of tension as indicated in the owner’s manual or on a label affixed to the machine itself; typically 3-4 foot pounds (or 4-5 Nm). Finally, use a torque wrench with a range of 10-12 ft lbs (13-16 Nm) to finish tightening each bolt head into place once they have been manually turned tight enough with an adjustable spanner or socket set. Doing so will ensure that both sides of your mower blade remain balanced while also providing maximum power transfer between its components when operating at full capacity.

What is the Torque on a Craftsman Riding Lawn Mower Blade?

The torque on a Craftsman riding lawn mower blade is determined by the size of the engine. Generally, most Craftsman riding lawn mowers are powered by Briggs & Stratton engines ranging from 12 to 24 horsepower. The larger these engines are, the more torque they produce and thus, the more power available for turning your blades.

This can be beneficial when cutting through thick grass or wet turf. Torque output varies between models but typically ranges from 8 foot-pounds up to 25 foot-pounds depending on the model you have chosen. It is important to note that too much torque can cause damage to your machine if used incorrectly so it’s important to use caution when operating a high-torque machine such as this one.

What is the Torque on a Walker Blade?

Torque is an important concept to understand when using a walker blade. Torque is the rotational equivalent of force, or in other words, it’s the measure of how much a force causes an object to rotate around its axis. The torque on a walker blade affects how easily and quickly it can propel you forward and turn corners.

It also has implications for power transfer from your arms to the wheels of the walker and therefore control over speed or direction changes. In order to get maximum efficiency out of your walker blades, you need to find the right balance between having enough torque for propulsion but not so much that it causes uncomfortable jerky movements or reduces maneuverability. This may require some trial-and-error as every person’s body weight, strength levels and even walking style are different!

What Size is John Deere Blade Nut?

John Deere blade nuts come in several sizes, depending on the model of lawnmower or tractor you are using. For example, the standard size for newer models is a 1/2 inch nut. However, older John Deere models use either a 7/8 inch or 3/4 inch nut for their blades.

You can measure your current blade and compare it to these standards to find out what size your John Deere blade nut needs to be. Additionally, when replacing the blades on any John Deere mower or tractor, you should always make sure that the blade nut size matches with its corresponding bolt thread diameter measurement. This will ensure that your new blades are secure and won’t fall off during use.

To sum up, there are several different sizes of John Deere blade nuts available but typically modern machines require a 1/2 inch nut while older ones may require either a 7/8 or 3/4 inch one – so make sure to check carefully before purchasing replacements!

Credit: landmarkimp.com

Briggs And Stratton Lawn Mower Blade Torque

Briggs & Stratton lawn mower blades should be torqued to the manufacturer’s specifications in order to ensure proper performance and safety. The torque for these blades can range from 80-90 ft-lbs depending on the model of your Briggs & Stratton lawn mower engine. It is important to use a torque wrench when tightening the blade bolts, as over-tightening can lead to damage or failure of the parts involved.

Craftsman Lawn Mower Blade Torque Specs

The torque specifications for attaching a Craftsman lawn mower blade to the engine crankshaft are important for proper operation and safety of your lawn mower. A standard Craftsman riding or push-style mower should have a torque specification of 27 – 30 ft/lbs, while larger commercial models may require up to 50 ft/lbs. It is always best to use a torque wrench when tightening the blade nut so you don’t over tighten and cause damage or risk injury.

Honda Lawn Mower Blade Torque

Honda Lawn Mowers require a specific torque when installing a new blade. This is important, as an incorrect torque can cause the blade to become loose or come off during use. When replacing the blade on your Honda lawn mower, be sure to follow manufacturer instructions for proper torque and tighten the bolt with a torque wrench to ensure maximum safety and performance of your machine.

Conclusion

This blog post has been a valuable resource for lawn owners and maintenance personnel looking to safely and correctly torque the blades of their John Deere mower. The information provided here is accurate, detailed, and easy to understand. This post will be an important reference for anyone needing to properly install or replace the blades in their John Deere mower.

With this knowledge, users can ensure that they are using the correct blade torque specs when maintaining their mowers for maximum performance and safety.