2001 7.3L Powerstroke Specs: The Definitive Guide (HP, Torque, & Towing)

The 7.3L Powerstroke diesel engine is not just a piece of engineering; it’s a legend. In the world of diesel trucks, no engine commands as much respect for its sheer reliability and simplicity. For owners, enthusiasts, and potential buyers, the 2001 model year represents a particularly important moment. It was the pinnacle of the 7.3L’s development, featuring the highest horsepower and torque figures of its entire production run.

However, the 2001 model also harbors a critical, model-specific nuance that every potential owner must understand: the connecting rod lottery. This was the year Ford began phasing in a different style of connecting rod, a change that has massive implications for performance and long-term durability.

This definitive guide provides a comprehensive, data-driven breakdown of all 2001 7.3L Powerstroke specs. We will cover the official horsepower and torque curves, provide clear-cut towing and fluid capacity charts, and—most importantly—give you the exact data needed to identify which engine internals are in your 2001 truck.

The 2001 7.3L Powerstroke: A Look at the Legend

Unmatched Performance

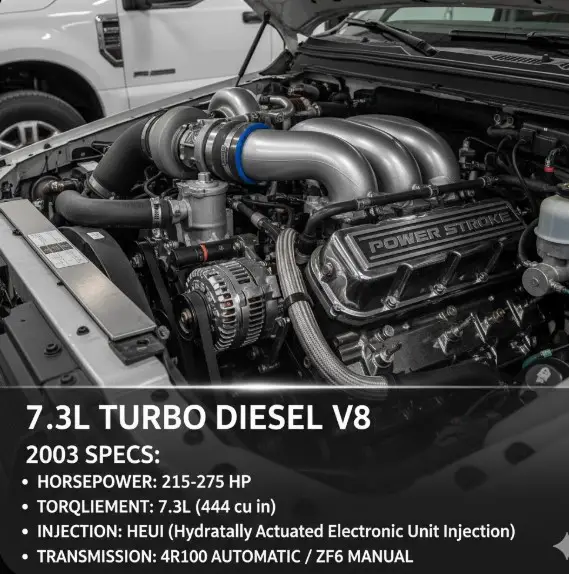

The 2001 model year marked a high point for the 7.3L, especially when paired with the 6-speed manual transmission, delivering robust power that defined a generation of diesel trucks.

Core Engine Specifications

Displacement

7.3L

(444 cu in)

Engine Type

V8

Turbocharged Diesel

Compression

17.5:1

Ratio

Fuel System

HEUI

Hydraulic Electronic Unit Injector

Bore

4.11 in

(104.4 mm)

Stroke

4.18 in

(106.2 mm)

Performance Curve (Manual)

This chart visualizes the relationship between Horsepower (HP) and Torque. Notice how torque peaks early at 1,600 RPM for massive pulling power, while horsepower builds steadily to its peak at 2,800 RPM.

Key Component: HEUI Fuel System

The 7.3L’s reliability is partly due to its innovative (for the time) HEUI system. It uses high-pressure engine oil to actuate the fuel injectors, a design different from common-rail systems.

1. Low-Pressure Fuel

Fuel pump sends fuel to injectors

2. High-Pressure Oil

HPOP sends oil to injectors

3. Actuation

Oil pressure fires the injector

4. Injection

Fuel atomizes into cylinder

Fluid Capacities

Proper maintenance is key. The 7.3L holds a significant amount of oil and coolant, crucial for its longevity and cooling performance under load.

The 7.3L Legacy

The 2001 7.3L is often considered the pinnacle of this engine’s run. It’s remembered for its relative simplicity, durability, and a distinct “diesel clatter” loved by enthusiasts. While not as powerful as modern engines, its reputation for reliability is legendary.

Strengths

- Legendary Reliability: Known to run for 500,000+ miles with proper care.

- Simplicity: Lacks the complex emissions systems of newer diesels.

- Strong Low-End Torque: Excellent for towing and hauling.

- Cast Iron Components: Features a cast-iron block and heads for durability.

Common Issues

- Cam Position Sensor (CPS): A well-known failure point, though an easy fix.

- Injector O-Rings: Can wear out over time, leading to oil-in-fuel issues.

- Glow Plug System: Relays and plugs can fail, causing hard starts in cold weather.

- Turbo “Surge”: Can occur when towing heavy at certain RPMs.

2001 7.3L Powerstroke Specs (At a Glance)

The 2001 7.3L Powerstroke is the final, most developed version of the 444-cubic-inch V8 turbo-diesel that Ford used from 1994.5 to 2003. This engine was not a Ford design but was manufactured by Navistar International as the “T444E,” a name synonymous with durability in commercial applications.

Here are the core architectural specifications for the 2001 model year engine.

2001 7.3L Powerstroke Core Specifications Table

| Specification | 2001 7.3L Powerstroke Value |

| Engine | Navistar T444E (Ford 7.3L Powerstroke) |

| Displacement | 7.3 Liters (444 cubic inches) |

| Configuration | 90° V8 Turbo-Diesel |

| Bore | 4.11 in (104.4 mm) |

| Stroke | 4.18 in (106.2 mm) |

| Valvetrain | 2-Valve OHV (16 valves total) |

| Compression Ratio | 17.5:1 |

| Injection System | Hydraulic Electronic Unit Injector (HEUI) |

| Turbocharger | Garrett GTP38 (Fixed Geometry) |

| Factory Applications | F-250/F-350/F-450/F-550 Super Duty, Ford Excursion |

Engine Performance: 2001 HP, Torque, & Real-World Dyno

The 2001 model year saw the 7.3L Powerstroke reach its factory performance peak. However, the official horsepower and torque ratings were not universal; they depended entirely on which transmission the truck was equipped with.

The 275 HP Exception: Why Your Transmission Matters

The primary source of confusion regarding 2001 specs is the power difference between automatic and manual trucks.

- Automatic (4R100): Trucks equipped with the 4-speed 4R100 automatic transmission were rated at 250 horsepower @ 2,600 RPM and 505 lb-ft of torque @ 1,600 RPM.

- Manual (ZF S6-650): Trucks that came with the 6-speed ZF S6-650 manual transmission received a more aggressive factory tune, bumping output to 275 horsepower @ 2,800 RPM and 525 lb-ft of torque @ 1,600 RPM.

This was not an arbitrary decision. The 4R100 automatic transmission, while improved over its E4OD predecessor, was the known “weak link” in the powertrain. Ford electronically de-tuned the engines in automatic models to protect the transmission from the engine’s full torque. The robust ZF 6-speed manual, by contrast, was more than capable of handling the engine’s “unleashed” factory tune.

This has a significant practical implication: owners of automatic-equipped trucks who plan performance modifications must budget for transmission upgrades, while manual-transmission owners have much more headroom from the start.

2001 7.3L Power Output by Transmission Table

| Transmission | Horsepower (Crank) | Torque (Crank) |

| 4-Speed Automatic (4R100) | 250 hp @ 2,600 RPM | 505 lb-ft @ 1,600 RPM |

| 6-Speed Manual (ZF S6-650) | 275 hp @ 2,800 RPM | 525 lb-ft @ 1,600 RPM |

Crank vs. Wheel Horsepower: Real-World Dyno Results

The factory ratings above are at the flywheel (crank). On a chassis dynamometer (“dyno”), power is measured at the wheels after drivetrain losses (from the transmission, transfer case, driveshaft, and axles).

While a 15-20% loss is typical, a healthy, stock 2001 7.3L Powerstroke can put down impressive numbers. One independent test of a 2001 F-350 dually (automatic) recorded 227 hp and 486 lb-ft at the rear wheels, showing remarkably little drivetrain loss. Other dyno events have shown similar stock trucks in the 226 hp / 426 lb-ft range.

For a prospective buyer, a healthy, stock 2001 7.3L should be expected to produce between 200-225 horsepower at the wheels.

The 2001 7.3L’s Critical Question: Forged or Powdered Metal Rods?

This is the single most important section for any 2001 7.3L owner or buyer. Unlike other model years, 2001 7.3L engines were built with two different types of connecting rods, and the difference is critical for performance.

What’s the Difference?

- Forged Steel Rods: These are the legendary, “bulletproof” rods found in all 1994.5-2000 7.3L engines. Forged rods are known for their immense strength and tendency to bend rather than break under extreme stress. These rods are the required foundation for any high-horsepower build, with many owners safely running 500hp or more on the stock forged internals.

- Powdered Metal Rods (PMRs): Ford began phasing in PMRs in late 2000 for the 2001 model year, primarily as a cost-saving measure. PMRs are strong, but they are also more brittle than forged steel. When they fail, they do not bend; they “snap clean off,” often destroying the entire engine block in the process.

The “Threshold for Pain”

The difference only matters if you plan to add significant power.

- Powdered Metal Rods (PMRs): The accepted “safe” limit for PMRs is around 400-450 rear-wheel horsepower (rwhp) and 800-900 lb-ft of torque.11 Pushing past this is a gamble.

- Forged Steel Rods: These rods can reliably handle well over 500 rwhp, making them the ideal platform for 7.3L Powerstroke performance upgrades.

Some online sources incorrectly claim all 7.3L engines had forged rods. This is verifiably false for the 2001 model year and a dangerous myth for anyone planning to modify their engine.

How to Identify Rods in Your 2001 7.3L

You cannot identify the rods by the truck’s VIN. You must check the engine itself. There are two definitive ways.

Method 1: By Engine Serial Number (The Best Way)

The 2001 production year saw Ford switch back and forth between rod types, likely due to supply chain issues with the new PMRs. This “waffling” is what makes identification so confusing.

Visual Plan: 2001 7.3L Connecting Rod Identification Table

| Engine Serial Number | Connecting Rod Type | Production Timeframe |

| 1,425,746 and prior | Forged | Start of production – Oct 2000 |

| 1,425,747 – 1,440,712 | Powdered Metal (PMR) | Late 2000 – Early 2001 |

| 1,440,713 – 1,498,318 | Forged | Mid-2001 (Supply shift) |

| 1,498,319 and after | Powdered Metal (PMR) | Mid-2001 – End of production |

Method 2: Physical Inspection

If you cannot find the serial number, you can perform a physical inspection.

- On the driver’s side of the engine block, there is a small, rectangular inspection plug.

- Remove this plug and use a light and a mirror (or borescope) to look inside at the connecting rods.

- Forged Rods: The rod cap is secured with a nut on a stud. The cap and rod have a rough, forged texture.

- PMRs: The rod cap is secured with a 12-point bolt head. The rod has a smooth, cast-like appearance and a distinct “fracture-split” seam.

Engine Architecture & Key Components

The 2001 7.3L’s performance and iconic sound are defined by its turbocharger and unique fuel system.

Turbocharger: The Garrett GTP38

All late-model 7.3L Powerstrokes, including the 2001, came equipped with a Garrett GTP38 fixed-geometry turbocharger. This was an update from the smaller, non-wastegated turbo used on early-1999 models. The GTP38 is a reliable workhorse, known for producing the 7.3L’s signature “whistle.” While durable for stock power levels, it is a common upgrade target, as modern aftermarket turbos can provide faster spool-up, lower exhaust gas temperatures (EGTs), and eliminate compressor surge.

Fuel System: The HEUI Injectors

The 7.3L does not use a common-rail system or a traditional injection pump. It uses a Hydraulic Electronic Unit Injector (HEUI) system.

This system uses a High-Pressure Oil Pump (HPOP) to send highly pressurized engine oil (up to 3,000 psi) to the injectors. This high-pressure oil is then used inside the injector body to pressurize fuel to over 20,000 psi, forcing it into the combustion chamber.

This design is exactly why oil quality is paramount in a 7.3L. The engine’s oil is not just a lubricant; it’s the hydraulic fluid that fires the injectors. Clean, fresh oil is essential for a healthy HEUI system.

For 2001, trucks used “AD” code split-shot injectors, which flow approximately 134-140cc. Many owners may also notice a single “AE” or “long lead” (LL) injector in the #8 cylinder. This was a factory solution for a common noise known as “engine cackle,” which was caused by the #8 cylinder being the last on the fuel rail.

2001 7.3L Powerstroke Fluid Capacities (Owner’s Guide)

Proper maintenance is the key to the 7.3L’s 500,000-mile reputation. Due to the high-shear-stress HEUI system, a strict 3,000- to 5,000-mile oil change interval is critical. Filling this 15-quart engine is the most important part of any.

Visual Plan: 2001 7.3L Powerstroke Fluid & Oil Capacity Table

| Fluid | Application / Specification | Capacity (Quarts) | Capacity (Liters) |

| Engine Oil | w/ Filter | 15.0 qts | 14.2 L |

| Engine Coolant | 50/50 Mixture | 32.8 qts | 31.0 L |

| Auto. Trans (4R100) | Mercon V (Total Fill) | 17.1 – 17.7 qts | 16.2 – 16.7 L |

| Auto. Trans (4R100) | Mercon V (Initial Fill) | ~6.4 qts | (data from ) |

| Manual Trans (ZF S6) | Synthetic MERCON | 5.8 qts | 5.5 L |

| Transfer Case | BW1536 | 2.0 qts | 1.9 L |

| Front Differential | Dana 50 IFS | 1.9 qts | 1.8 L |

| Front Differential | Dana 60 | 2.9 qts | 2.7 L |

| Rear Differential | Sterling 10.50 | 3.45 qts | (data from) |

| Rear Differential | Dana 80 | 4.15 qts | (data from) |

2001 7.3L Powerstroke Towing Capacity

The 7.3L Powerstroke was built to tow. However, the official tow rating is one of the most misunderstood specs. It’s crucial to understand that the 7.3L’s towing capacity is limited by the truck’s configuration, not just the engine’s power.

A common misconception comes from the conventional hitch (the receiver under the bumper), which on all 2001 F-250/F-350 models was limited to 10,000 lbs.

To unlock the 7.3L’s true potential, a 5th-wheel hitch is required. The maximum 5th-wheel tow rating is highly variable, depending on four factors:

- Model: F-250 vs. F-350 Single Rear Wheel (SRW) vs. F-350 Dual Rear Wheel (DRW)

- Drivetrain: 4×2 vs. 4×4

- Cab: Regular, SuperCab, or Crew Cab (which affects the truck’s base weight)

- Axle Ratio: 3.73 vs. 4.10

As the data shows, the single biggest factor is the axle ratio. Simply opting for the 4.10 axle ratio over the 3.73 can increase the maximum 5th-wheel tow capacity by as much as 3,000 pounds.

The table below is sourced from the official 2001 Ford Towing Guide. Always confirm your specific truck’s ratings on the door jamb sticker.

Visual Plan: 2001 7.3L Powerstroke 5th-Wheel Towing Capacity

| Vehicle Model | Cab/Drive | Axle Ratio | GCWR (Lbs.) | Max Trailer (Auto) | Max Trailer (Manual) |

| F-250 | Reg Cab / 4×2 | 3.73 | 17,000 | 11,000 | 10,400 |

| F-250 | Reg Cab / 4×2 | 4.10 | 20,000 | 14,000 | 13,400 |

| F-250 | SuperCab / 4×2 | 3.73 | 17,000 | 11,100 | 10,400 |

| F-250 | SuperCab / 4×2 | 4.10 | 20,000 | 14,100 | 13,400 |

| F-250 | Crew Cab / 4×2 | 3.73 | 17,000 | 10,800 | 10,100 |

| F-250 | Crew Cab / 4×2 | 4.10 | 20,000 | 13,800 | 13,100 |

| F-250 | Reg Cab / 4×4 | 3.73 | 17,000 | 10,700 | 10,400 |

| F-250 | Reg Cab / 4×4 | 4.10 | 20,000 | 13,700 | 13,400 |

| F-250 | SuperCab / 4×4 | 3.73 | 17,000 | 10,800 | 10,400 |

| F-250 | SuperCab / 4×4 | 4.10 | 20,000 | 13,800 | 13,300 |

| F-250 | Crew Cab / 4×4 | 3.73 | 17,000 | 10,400 | 10,000 |

| F-250 | Crew Cab / 4×4 | 4.10 | 20,000 | 13,400 | 12,900 |

| F-350 SRW | Crew Cab / 4×2 | 3.73 | 17,000 | 10,800 | 10,100 |

| F-350 SRW | Crew Cab / 4×2 | 4.10 | 20,000 | 13,800 | 13,100 |

| F-350 SRW | Crew Cab / 4×4 | 3.73 | 17,000 | 10,000 | 9,600 |

| F-350 SRW | Crew Cab / 4×4 | 4.10 | 20,000 | 13,000 | 12,600 |

| F-350 DRW | Crew Cab / 4×2 | 3.73 | 20,000 | 13,000 | 12,600 |

| F-350 DRW | Crew Cab / 4×2 | 4.10 | 20,000 | 13,000 | 12,600 |

| F-350 DRW | Crew Cab / 4×4 | 3.73 | 20,000 | 12,900 | 12,600 |

| F-350 DRW | Crew Cab / 4×4 | 4.10 | 20,000 | 12,900 | 12,600 |

Real-World Ownership: Reliability & Fuel Economy

A 20+ year-old truck’s reputation is built on real-world performance. Here’s what decades of ownership have revealed.

Common (and Manageable) 7.3L Problems

The 7.3L is considered “legendary” not because it never breaks, but because its common failure points are well-documented, inexpensive, and easy to fix. Unlike its 6.0L successor, the 7.3L is not known for catastrophic “hard part” failures like head gaskets.

Its primary weak points are accessories, sensors, and wiring:

- Cam Position Sensor (CPS): This is the #1 most common issue. A faulty CPS can cause the engine to cut out while driving or fail to start. This part is inexpensive, easy to replace, and so notorious that most 7.3L veterans keep a spare in their glovebox.

- Injection Pressure Regulator (IPR) Valve: Located on the HPOP, this valve’s sensor can fail, or the valve itself can stick, leading to rough running, loping, or stalling.

- Under Valve Cover Harness (UVCH): The wiring harness connectors inside the valve cover can become loose or short out from heat and oil. This often manifests as a “lope” or “sputter” as one or more injectors lose their connection.

2001 7.3 Powerstroke MPG

When browsing forums, you will see optimistic claims of 24-28 mpg. These are not realistic for most owners. The 7.3L is a 444-cubic-inch V8 in a 7,000-pound truck; it was built for power, not efficiency.

A realistic expectation for a stock 2001 7.3L Powerstroke is:

- Mixed/City: 14-15 mpg

- Highway (empty): 16-17.5 mpg when driven conservatively

- Towing: 9-12 mpg, depending heavily on the load and terrain.

How the 2001 7.3L Stacks Up (Market Context)

To understand the 7.3L’s legacy, it’s helpful to see it in the context of its rivals and its replacement.

- 7.3L vs. 2001 5.9L Cummins: In 2001, Ford was winning the “spec war.” The 275 hp / 525 lb-ft from the manual 7.3L narrowly beat its chief rival, the 2001 Dodge Ram’s 5.9L Cummins 24v “High Output” (H.O.), which was rated at 245 hp and 505 lb-ft.

- 7.3L vs. 2003 6.0L Powerstroke: The 7.3L was at its absolute development limit. To meet impending, stricter emissions standards and leapfrog the competition, Ford introduced the 6.0L Powerstroke in 2003. With 4-valve heads and a modern Variable Geometry Turbo (VGT), the 6.0L debuted with a massive 325 hp and 560 lb-ft of torque. On paper, it made the 7.3L obsolete. However, this new complexity came at the cost of the 7.3L’s legendary reliability.

Visual Plan: 2001 Diesel Spec War (7.3L vs. 5.9L vs. 6.0L)

| Engine | Horsepower | Torque |

| 2001 7.3L Powerstroke (Manual) | 275 hp | 525 lb-ft |

| 2001 5.9L Cummins 24v (H.O.) | 245 hp | 505 lb-ft |

| 2003 6.0L Powerstroke (Successor) | 325 hp | 560 lb-ft |

This table tells a critical story: the 2001 7.3L represents the last, most powerful version of a simple, reliable engine design before emissions regulations forced a move to more complex—and initially problematic—technologies. This is why many owners prefer it, even with its lower power figures, leading to a vibrant aftermarket and a lasting debate on the 7.3L Powerstroke vs. 6.0L Powerstroke.

Conclusion: Is the 2001 7.3L Powerstroke a Good Engine?

Yes. The 2001 7.3L Powerstroke is widely considered one of the most reliable and sought-after heavy-duty diesel engines ever produced. It offers a “sweet spot” of modern-enough convenience with pre-emissions simplicity. The 275-horsepower manual transmission models are the most capable and desirable.

Its legendary status is built on a foundation of robust “hard parts.” Its few common problems are sensor- and wiring-related, making them inexpensive and easy to diagnose.

Its only significant variable is the connecting rod lottery. For the 9 out of 10 owners who will use the truck for daily driving and towing within its limits, either engine (PMR or forged) is exceptionally reliable. The distinction is only critical for the 10% of owners who plan to build a 450+ horsepower performance machine.

By checking the serial number, any 2001 7.3L owner can know exactly what they have, securing their place in the legacy of one of the greatest diesel engines of all time.

Frequently Asked Questions (FAQs)

Q: How much horsepower does a 2001 7.3L Powerstroke have?

A: It depends on the transmission. Models with the 4-speed automatic transmission have 250 horsepower. Models with the 6-speed manual transmission have a higher-output tune for 275 horsepower.

Q: How can I tell if my 2001 7.3L has forged rods?

A: You must check the engine serial number (S/N). For example, engines with S/Ns 1,440,713–1,498,318 (built in mid-2001) are forged. You can also remove the inspection plug on the block: a rod cap held on by a nut on a stud is forged, while a bolt head indicates a powdered metal rod (PMR).

Q: What is the towing capacity of a 2001 F-250 7.3L?

A: With a 5th-wheel hitch, a 2001 F-250 7.3L can tow between 10,000 and 14,100 pounds. The exact rating depends on cab type (Regular, SuperCab, Crew), drivetrain (4×2 or 4×4), and axle ratio (3.73 or 4.10).25 Conventional towing with the factory hitch is limited to 10,000 pounds.

Q: How much oil does a 2001 7.3L Powerstroke take?

A: The 2001 7.3L Powerstroke has an engine oil capacity of 15 quarts (14.2 Liters) with a filter change. This large capacity is required because the HEUI injection system uses engine oil as hydraulic fluid.

Q: Is the 2001 7.3L a good engine?

A: Yes, it is widely considered one of the most reliable diesel engines Ford ever produced. Its reputation is built on strong internal components and a lack of complex, failure-prone emissions systems. Its most common issues are well-documented and typically inexpensive to repair, such as the Cam Position Sensor (CPS).