24V Cummins Crank Sensor Location: Unveiling the Power Within

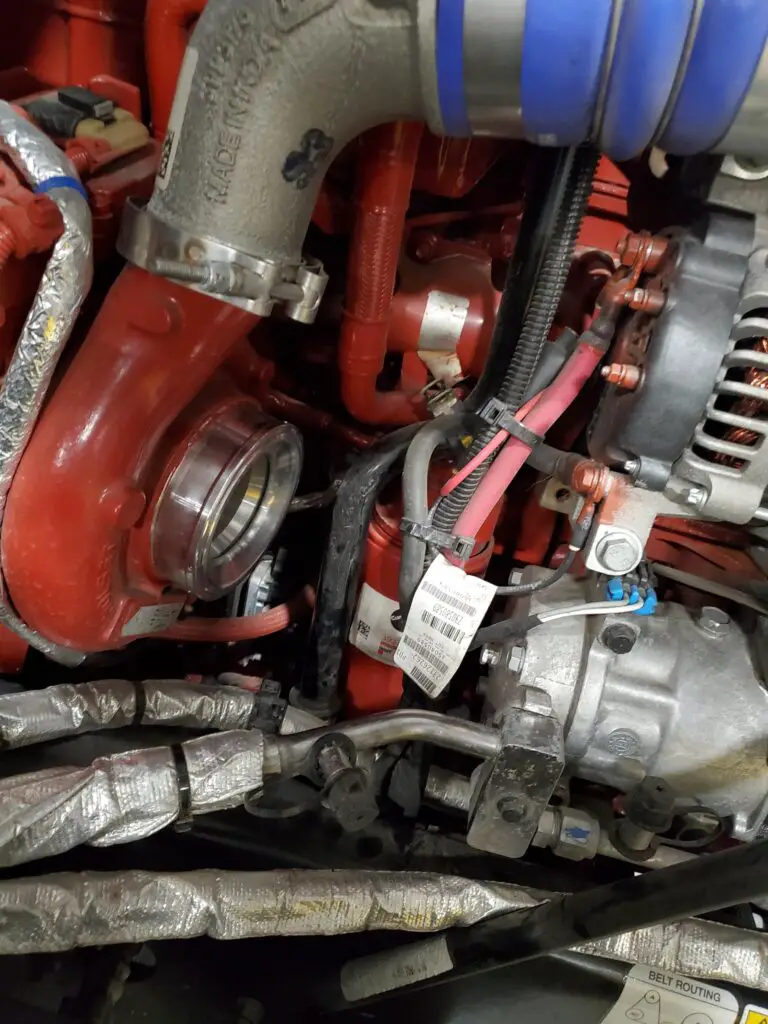

The 24V Cummins crank sensor is typically located on the left rear side of the engine block near the starter motor.

Credit: issuu.com

Understanding The Role Of The Crank Sensor

Understanding the role of the crank sensor is crucial for locating the 24V Cummins crank sensor. This sensor, typically located on the damper pulley of the engine balancer, is vital for accurate engine operation and can impact performance and fuel efficiency.

Understanding the Role of the Crank Sensor The crank sensor is a crucial component in the 24V Cummins engine, playing a vital role in its overall performance. It is responsible for monitoring the position and speed of the crankshaft, providing accurate information to the engine control unit (ECU). This data allows the ECU to precisely control ignition timing and fuel injection. What is a crank sensor and how does it work? A crank sensor, also known as a crankshaft position sensor, is a magnetic sensor that detects the rotation of the crankshaft. It typically consists of a permanent magnet, a coil, and a reluctor wheel. As the crankshaft rotates, the reluctor wheel passes by the crank sensor. This creates a magnetic field disturbance, which is sensed by the coil. The coil generates an electrical signal that is sent to the ECU for processing. Significance of the crank sensor in the 24V Cummins engine The crank sensor’s accurate measurement of the crankshaft’s position and speed is essential for the engine’s proper functioning. It allows the ECU to ensure precise ignition timing, fuel injection, and overall engine performance. Without a functioning crank sensor, the engine may experience various issues, such as rough running, poor fuel economy, and even starting or stalling problems. Timely diagnosis and replacement of a faulty crank sensor are crucial to maintain the performance and longevity of the 24V Cummins engine. To summarize, the crank sensor plays a vital role in the 24V Cummins engine’s performance by providing accurate information about the crankshaft’s position and speed. This enables the ECU to control ignition timing and fuel injection with precision, ensuring optimal engine performance.Locating The Crank Sensor In A 24v Cummins Engine

| 24V Cummins Crank Sensor Location |

|---|

Locating the crank sensor in a 24V Cummins engine is essential for troubleshooting and maintenance. There are several common locations for the crank sensor, each with its own advantages and disadvantages.

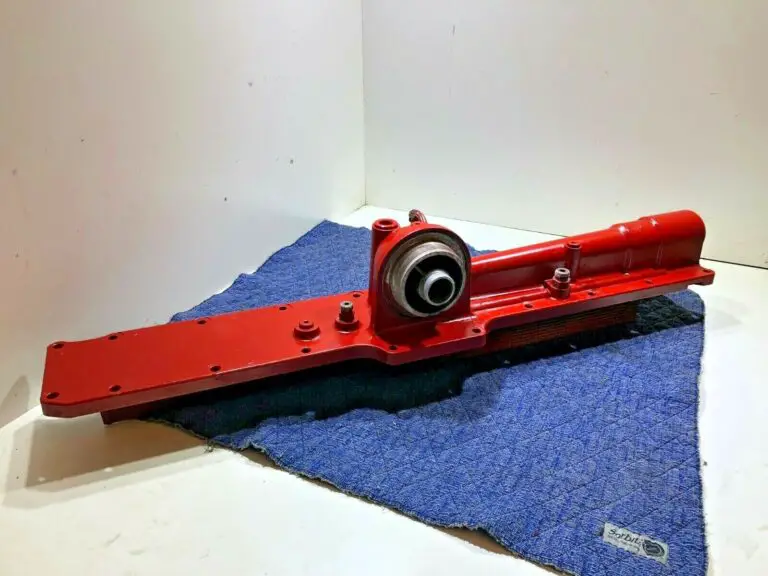

One common location is on the damper pulley of the engine balancer. This location allows for easy access and visibility but may be prone to damage from debris or other engine components.

Another location is behind the pump, commonly known as the cam sensor. This location offers protection from debris but may be more difficult to access.

Some engines have the crank sensor located behind the starter motor. This location provides good protection but may require removing the starter for access.

Other possible locations include the left rear side of the engine block near the starter motor, the engine block at the base of the engine oil dip, or above the harmonic balancer reading off of the engine damper.

It’s important to consult the manufacturer’s guidelines or a professional mechanic to ensure proper identification and location of the crank sensor in a 24V Cummins engine.

Tips For Finding The Crank Sensor In Your 24v Cummins Engine

Locating the crank sensor in your 24V Cummins engine may seem like a daunting task, but with the right tools and techniques, it can be a breeze. Here is a step-by-step guide to help you find the crank sensor:

- Start by opening the hood of your truck and locating the engine.

- Look for the crankshaft balancer, which is typically located at the front of the engine.

- The crank sensor is usually mounted on or near the balancer.

- Use a flashlight to get a better view and inspect the area around the balancer for any sensors.

- If necessary, refer to your vehicle’s service manual or online resources for specific diagrams and visuals.

By following these steps, you can easily locate the crank sensor in your 24V Cummins engine. Remember to use caution and take your time to ensure a successful search.

How Can I Tell If My 24v Cummins Crank Sensor Is Faulty?

When it comes to a faulty 24V Cummins crank sensor, it is crucial to address the issue promptly to avoid further damage. But how can you tell if your crank sensor is faulty? There are several common symptoms that may indicate a failing crank sensor. These include Check Engine Light illumination, hard starting and/or stalling, engine running rough or misfiring, and poor fuel economy.

A bad crankshaft sensor can cause engine sputtering, increased fuel consumption, engine stall, and difficulty in acceleration. It is important to have your car checked by a professional auto mechanic when you experience these symptoms as your car engine cannot function efficiently and may eventually fail completely.

The exact location of the crankshaft position sensor can vary depending on the specific engine model. It is commonly found on the damper pulley of the engine balancer, behind the pump or cam sensor, behind the starter, or in the engine block near the starter motor.

Replacing the crankshaft position sensor is a job best left to experts. If you suspect a faulty crank sensor, it is recommended to consult a professional mechanic for diagnosis and repair.

Can A Bad Crank Sensor Cause A No-start Condition In A 24v Cummins Engine?

When it comes to a 24V Cummins engine, a bad crank sensor can indeed cause a no-start condition. The crank sensor is responsible for identifying the position and rotational speed of the crankshaft, which is crucial for proper engine function. If the crank sensor is faulty, it may not send the correct signals to the engine control unit, resulting in starting issues.

If you suspect that a bad crank sensor is causing a no-start condition in your 24V Cummins engine, there are a few steps you can take to address the issue. First, it’s essential to diagnose the problem accurately. This can be done using diagnostic tools or by consulting a professional mechanic. Once the faulty crank sensor is identified, it should be replaced with a new one that is compatible with your engine model.

Replacing a crank sensor requires some technical knowledge and experience, so it’s recommended to seek professional help if you’re not confident in your abilities. Additionally, regular maintenance and inspections can help prevent crank sensor issues and ensure optimal engine performance.

What Are The Potential Risks Of An Improperly Located Crank Sensor?

What are the potential risks of an improperly located crank sensor?

Effects of a poorly located crank sensor on engine performance and longevity:

- Decreased engine efficiency and power.

- Inaccurate ignition timing.

- Increased fuel consumption.

- Engine misfires and rough idle.

- Difficulty in starting or engine stalling.

- Potential damage to engine components.

- Reduced overall engine lifespan.

How to avoid or correct an improperly located crank sensor:

- Consult the vehicle manufacturer’s guidelines to determine the correct location.

- Ensure proper installation and alignment.

- Regularly inspect and maintain the sensor for any signs of damage or displacement.

- Seek professional assistance if in doubt or experiencing any issues with engine performance.

- Do not attempt to relocate or modify the sensor without expert knowledge.

Frequently Asked Questions For 24v Cummins Crank Sensor Location

What Are The Symptoms Of A Failing Crank Sensor?

The symptoms of a failing crank sensor include: Check Engine Light illumination, hard starting and/or stalling, engine running rough or misfiring, and poor fuel economy. It is important to have a professional mechanic check your car when experiencing these symptoms.

What Are The Symptoms Of A Bad Crankshaft Sensor Diesel?

Symptoms of a bad crankshaft sensor diesel include check engine light, hard starting, engine runs rough, poor fuel economy. Get your car checked by a professional when experiencing sputtering, increased fuel consumption, engine stall, and difficulty in acceleration. A bad crankshaft sensor can lead to engine failure.

Where Is The Map Sensor On A 24v Cummins?

The map sensor on a 24V Cummins is located on the left rear side of the engine block near the starter motor.

Where Is The Exact Location Of The Crankshaft Position Sensor?

The crankshaft position sensor is typically located on the damper pulley of the engine balancer. It is essential for the proper operation of modern engines with fuel injection systems. KLM Performance.

Conclusion

The 24V Cummins crank sensor location is crucial for diagnosing potential issues with your engine. By understanding where the sensor is located, you can easily access and replace it if needed. Remember to pay attention to common symptoms such as engine sputtering, increased fuel consumption, engine stall, and difficulty in acceleration, as they may indicate a faulty crank sensor.

If you experience any of these symptoms, it’s important to have your car checked by a professional auto mechanic to ensure your engine’s efficiency and prevent complete failure.