Decoding the 5.7 Hemi Tick at Idle: An Owner’s Complete Guide 2025

The “Hemi tick” is one of the most feared phrases in the Mopar community, echoing in the forums for Ram 1500, Dodge Charger, Dodge Challenger, and Jeep Grand Cherokee owners. Hearing an unexpected “ticking” or “tapping” from the engine bay of a 5.7L Hemi V8 is a source of widespread frustration, anxiety, and online confusion.

The core of this anxiety stems from a simple problem: the “Hemi tick” is not one specific sound. It is a catch-all term that owners use to describe at least four distinct noises, each with a vastly different cause, severity, and repair cost. These noises range from being perfectly normal and harmless to being the first symptom of catastrophic, multi-thousand-dollar internal engine failure.

This guide will serve as a definitive diagnostic filter. Using data from professional mechanics, engine builders, and official Technical Service Bulletins (TSBs), this report will systematically help Hemi owners:

- Identify which of the four “ticks” they are hearing.

- Understand the specific engineering or mechanical reason why it is happening.

- Know the exact steps to fix it, how much it will cost, and what parts are required.

- Implement a clear, data-driven plan to prevent the “true,” fatal Hemi tick from ever happening.

The “Hemi Tick”

An Owner’s Diagnostic Guide to That Ticking Noise

What’s That Noise?

That persistent ticking sound at idle is a common complaint among 5.7 Hemi owners. While often called the “Hemi tick,” it isn’t one single problem. It’s a symptom that can point to several different issues, ranging from minor to critical. This chart breaks down the most common culprits based on owner reports and mechanic diagnoses.

How Bad Is It For Your Wallet?

The cost to fix the “Hemi tick” varies dramatically based on the root cause. A simple exhaust leak is often a manageable repair, but an internal engine issue like lifter failure is one of the most expensive repairs outside of a full engine replacement. This visualization compares the typical high-end repair costs for the most common failures.

Diagnostic Flow: What to Do First

Before you panic, follow a logical diagnostic path. The sound’s location and timing can tell you a lot. This flow chart outlines the steps you or your mechanic should take to pinpoint the source of the tick. Remember, a misdiagnosis can be costly.

A clear, rhythmic tap-tap-tap is present.

Is it low? Is it the correct 5W-20 synthetic?

- Worse when COLD, quiet when HOT? Often an exhaust manifold leak.

- Persistent or worse when HOT? Points toward internal engine (lifters, spring).

- Loudest at Exhaust Manifold? Likely broken manifold bolts.

- Loudest at Valve Cover? Likely valvetrain (lifter, spring).

Codes like P0300, P0301, etc., often signal a failing lifter or spring.

Prevention is the Best Medicine

While some issues are design-related, proper maintenance is the single best way to protect your Hemi’s valvetrain and prolong its life. Ignoring these simple steps can lead to premature wear and costly lifter failure.

-

✓

Use the Correct Oil: Always use a high-quality, API-certified 5W-20 synthetic oil that meets Chrysler’s MS-6395 spec.

-

✓

Shorten Oil Change Intervals: Do not exceed 5,000-6,000 miles between changes, even with synthetic. Clean oil is crucial for hydraulic lifters.

-

✓

Allow Proper Warm-Up: Let the engine idle for 30-60 seconds before driving, and avoid heavy acceleration until the oil is at operating temperature.

-

✓

Avoid Excessive Idling: The MDS (Multi-Displacement System) can be harder on lifters during long idle periods.

What is the Hemi Tick? (And Which One Do You Have?)

The first and most critical step in diagnosis is to observe when the tick occurs. The difference between a tick that happens when the engine is cold versus one that only appears when the engine is hot is the single most important diagnostic factor.

What an owner hears, and when they hear it, is the key to differentiating between a harmless noise and a ticking time bomb.

Diagnostic Comparison Table: The Four Hemi Ticks

This table synthesizes data from multiple mechanic and owner reports to provide a clear diagnostic starting point.

| Cause of Tick | Sound Description | When It Happens (Hot/Cold) | Is It Dangerous? |

| Normal Fuel Injector Noise | Steady, fast “click-click-click” | Always present, at all RPMs | No. This is normal operation. |

| Normal Lifter Bleed-Down | “Rattle” for 2-10 seconds | Only on cold start (after sitting) | No. This is normal as oil pressure builds. |

| Exhaust Manifold Leak | Loud “tick-tick-tick” | Loud on cold start, disappears when warm | No (Not Fatal). Needs fixing, but your engine isn’t in danger. |

| “True” Lifter/Cam Failure | Soft, random “ping” or “rap” | Only when engine is hot and at idle | Yes (Catastrophic). Stop driving and diagnose. |

Benign Hemi Noises: Ticks You Can Ignore

Before assuming the worst, it is essential to know that Hemi engines are not silent. They are known for being mechanically noisy, and two of the most common “ticks” are completely normal.

Normal Fuel Injector Noise

- Explanation: This is the sound of the engine’s high-pressure fuel injectors operating. As they open and close rapidly to spray fuel into the cylinders, they produce a distinct, light “click-click-click” or “tapping” sound.

- Diagnosis: The key identifier is that this sound is constant. It is present at idle and at all engine speeds, though it is often drowned out by road and engine noise as RPMs increase. This steady clicking is a normal and harmless characteristic of the 5.7 Hemi and many other modern, direct-injected or port-injected engines.

Normal Hydraulic Lifter Bleed-Down (Cold Start Rattle)

- Explanation: The 5.7 Hemi uses hydraulic lifters, which are small components that use oil pressure to maintain zero valve lash (the gap in the valvetrain). After the engine has been turned off for an extended period (like overnight), oil can drain from these lifters, a process called “bleed-down.”

- Diagnosis: For the first few seconds of a cold start, before the oil pump has built sufficient pressure to “pump up” the lifters, the valvetrain can be noisy. This sound is a “rattle” that lasts only 2 to 10 seconds after a cold start and then disappears completely. Ram/Chrysler have even noted in some owner’s manuals that this brief start-up noise is normal.8 It is critical to differentiate this 2-10 second normal rattle from the abnormal exhaust manifold tick, which can last for 30 seconds to several minutes.

The Common (and Less Scary) Tick: Exhaust Manifold Leaks

This is the most common abnormal noise and the one most frequently confused with the dreaded lifter failure. It is a design flaw, but it is not a threat to the engine’s internal health.

How to Diagnose the Exhaust Manifold Tick

- The “Smoking Gun” Symptom: The sound is a loud, rhythmic “tick-tick-tick” that is present only on a cold start and goes away (or becomes significantly quieter) once the engine has warmed up.

- The Physics Behind It: This behavior is the key diagnostic. The tick is caused by a crack in the exhaust manifold or a gap created by a broken manifold bolt. When the engine is cold, this gap allows small puffs of exhaust gas to escape, creating the “tick” sound. As the cast iron manifold heats up, it expands, which seals the crack or gap and stops the noise.5 This behavior is the complete opposite of the “true” lifter tick.

- DIY Diagnostic Tests:

- Listen at the Wheel Well: The sound is often loudest when listening from the driver or passenger side wheel well, as this is closest to the manifold’s location.

- Check the Heat Shield: When the engine is completely cold, carefully reach in and try to wiggle the thin metal heat shield covering the exhaust manifold. If the shield moves or rattles, it is a very strong sign that the bolts holding it (and the manifold) have broken.

The Engineering Cause: Why Manifold Bolts Break

This issue is a well-known design flaw in the Gen 3 Hemi.

- The Causal Chain:

- The 5.7 Hemi engine block and cylinder heads are made of aluminum.

- The factory exhaust manifolds (headers) are made of cast iron.

- Aluminum and cast iron expand and contract at different rates when they heat up and cool down.

- This constant differential stress, cycle after cycle, puts enormous strain on the steel bolts that hold the manifold to the head.

- Over time, this strain causes the manifold itself to warp or, most commonly, the manifold bolts to snap (especially the rearmost bolts).

- This creates the gap that allows exhaust to escape, causing the tick.

Repairing the Exhaust Manifold Tick: Costs & TSBs

- The Official TSB: Stellantis (Chrysler/Ram) has formally acknowledged this problem. Technical Service Bulletin (TSB) 09-001-24, issued on January 20, 2024, directly addresses “a ticking noise from the exhaust manifold location(s) when cold” on 2019-2024 Ram 1500 models (Dodge TSBs often apply to other models with the same engine).

- The Fix: The official TSB procedure involves replacing the cracked or warped manifold and all associated fasteners with an updated kit.

- Cost Analysis:

- Dealer/Shop (OEM): RepairPal estimates the average cost for one side to be between $632 and $910. However, this is a baseline. Forum members frequently report shop quotes as high as $1,600 due to the labor involved.17

- DIY: The parts (gaskets, bolts) are relatively inexpensive. The high cost is 100% labor. The bolts often break off flush with the cylinder head, turning a simple bolt-on job into a “shitty job” that requires precise drilling and bolt extraction, often in a very tight space.

- The Upgrade: Many owners and shops recommend not replacing the faulty OEM manifolds with another set that will fail again.17 Instead, they upgrade to aftermarket “shorty” headers, which often use a thicker flange and may be less prone to the warping that causes the issue.

- Official TSB Link (External):(https://static.nhtsa.gov/odi/tsbs/2024/MC-10251862-9999.pdf)

- Internal Link: This manifold flaw is one of several well-documented issues.

The “True” Hemi Tick: Catastrophic Lifter and Camshaft Failure

This is the tick. This is the one that owners fear, and for good reason. This sound is not an external leak; it is the sound of the engine’s internal components failing and grinding against each other.

How to Diagnose the Lifter Failure Tick

- The “Smoking Gun” Symptom: This is the most critical diagnostic takeaway. The “true” Hemi tick is a soft “ping,” “rap,” or “tapping” noise that occurs only after the engine is fully warmed up and is only present at hot idle.

- Key Behavior: In its early stages, the tick goes away when the engine is revved off idle. This is because the increased RPMs raise oil pressure and, more importantly, oil splash, which temporarily lubricates the failing part and quiets the noise. This is the exact opposite of the exhaust manifold tick.

- Progression of Failure:

- Early Stage: A soft, intermittent “ping” or “rap” is heard only at hot idle.

- Mid-Stage: The tick becomes a louder, more consistent “rap-rap-rap” and may increase in frequency with RPMs instead of disappearing.

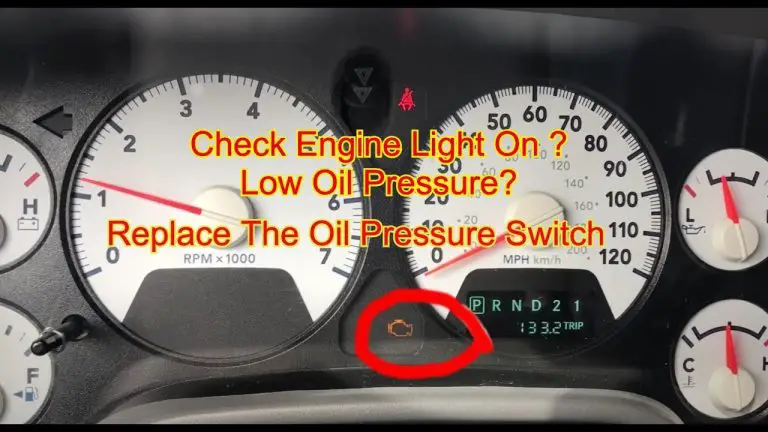

- Late Stage: The lifter’s roller bearing seizes completely. The roller stops spinning and is “skidded” across the camshaft lobe, destroying it. This will cause a “dead” cylinder, resulting in a rough idle, significant lack of power, and a Check Engine Light with a misfire code, typically P0300 (Random Misfire) or a cylinder-specific code (e.g., P0301-P0308).

The Critical Dealer Diagnostic: Check the OCV for Metal

When a customer complains of these late-stage symptoms, dealers have an official diagnostic path. STAR Case S1709000010 outlines the procedure when “abnormal engine noise,” “rough idle,” “misfire,” and “excessive camshaft lobe wear/lifter wear” are suspected.

- The Procedure:

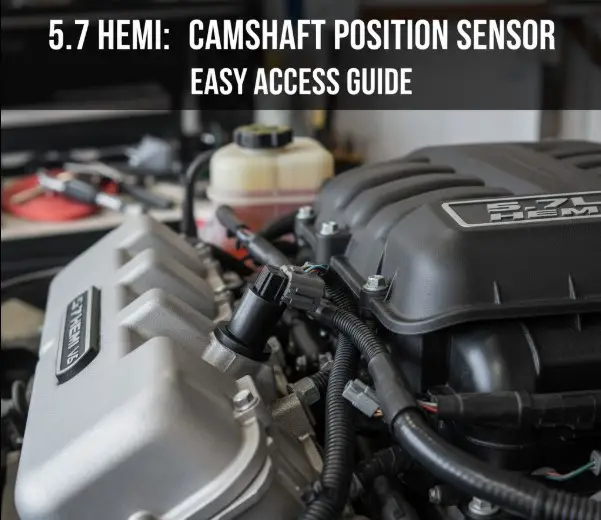

- The technician removes the Oil Control Valve (OCV) for the Variable Valve Timing (VVT) system.

- They inspect the fine mesh screens on the OCV for any metal debris.

- The Two Outcomes:

- No Debris Found: This is the best-case scenario. It suggests the failure may be isolated to the valvetrain. The technician can proceed with replacing only the camshaft and all 16 lifters.

- Debris Found: This is the nightmare scenario. Metal debris on the OCV screen is proof that the ground-up metal from the cam and lifter has circulated through the entire oiling system. This metal “glitter” contaminates the oil pump, scores the main and rod bearings, and destroys the engine from the inside out. In this case, a simple cam/lifter replacement is pointless; engine replacement is often the only required repair.

- Official TSB Link (External):(https://static.nhtsa.gov/odi/tsbs/2021/MC-10215879-9999.pdf)

The Engineering Root Cause: Why 5.7 Hemi Lifters Really Fail

This section establishes the true expertise, moving beyond simple problem-listing to explain the fundamental, third-order “why.” The problem is not just “bad lifters” ; it is a systemic design flaw in the Gen 3 Hemi’s oiling system.

A “Backwards” Oiling System

According to detailed technical analysis from engine builders, the Gen 3 Hemi (2009+ “Eagle”) oils its top end in a unique, “backwards” manner compared to other pushrod V8s.

- The Oil Path:

- Oil is pumped up to the block/head.

- It oils the rocker arm shafts first.

- It then flows through the rocker arm and down the hollow pushrod.

- It finally exits the pushrod to fill the body of the hydraulic lifter.

- The Critical Flaw: The body of the lifter receives pressurized oil, which is what it needs to function as a hydraulic cushion. However, the part that actually fails—the lifter roller axle bearing—is not pressure-fed. This tiny needle bearing, which allows the lifter’s roller wheel to spin on the cam lobe, relies 100% on “splash” and “drip” lubrication from oil being flung off the crankshaft and dripping down from the heads.

The #1 Killer: Extended Idling

This oiling design directly leads to the root cause of the failure.

- The Causal Chain:

- The lifter roller bearings require oil splash to survive.

- At low engine speeds, specifically idle (around 600 RPM), the crankshaft is not spinning fast enough to create adequate oil “splash” to lubricate the valvetrain.

- The Hemi’s high-mounted camshaft design also places it farther from the crankshaft, further reducing the amount of splash it receives.

- Result: During long periods of idling, the lifter roller bearings are effectively starved of oil.

- The starved, dry bearing overheats, seizes, and the roller wheel stops spinning. The now-stationary roller “skids” along the rapidly spinning cam lobe, grinding both parts into metal shavings.

- The Evidence: This engineering theory is proven by real-world data. Fleet and police vehicles (like Dodge Chargers), which idle for 12+ hours a day, see the highest rates of lifter failure, often at very low mileage. The #1 piece of advice from mechanics is to limit hot idling whenever possible.

The 5W-20 vs. 5W-30 Oil Debate

This oiling flaw is compounded by the manufacturer’s oil specification.

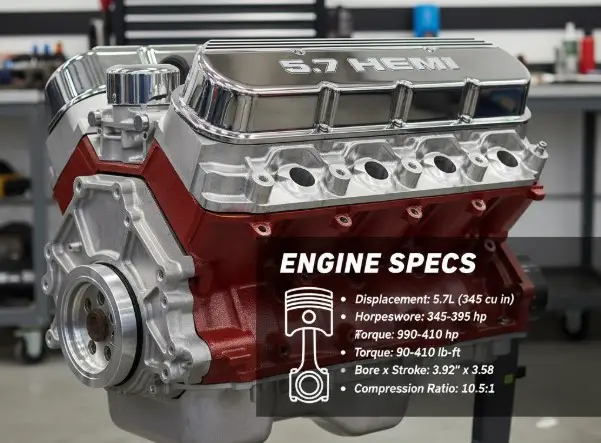

- The Context: The 5.7 Hemi in the Ram 1500 (and other 1500-platform vehicles) specifies 5W-20 motor oil. However, the exact same 5.7 Hemi engine, when placed in a “severe duty” Ram 2500 or 3500 truck, specifies 5W-30 oil.

- The “Why”: The 5W-20 specification is widely believed to be for meeting corporate average fuel economy (CAFE) standards—a thinner oil has less drag, marginally improving MPG. It is not for maximum engine longevity.

- The Argument for 5W-30: A high-quality full synthetic 5W-30 oil provides a more robust, “stickier” oil film and, more critically, higher oil pressure at hot idle. This increased oil pressure/volume at idle directly combats the oil starvation root cause. Owners who have monitored their oil pressure report a significant increase at hot idle (e.g., from 29 psi on 5W-20 to 37 psi on 5W-30) after making the switch.

Does the MDS System Cause Lifter Failure?

The Multi-Displacement System (MDS), which deactivates four cylinders to save fuel, is often blamed because failures seem to occur on the MDS-specific lifters.

- The Misconception: The MDS lifters are indeed more complex components.

- The Nuanced Truth: The part of the lifter that fails is not the MDS-specific hydraulic mechanism. It is the roller axle bearing, which all 16 lifters (MDS and non-MDS) possess.

- Expert Consensus: The MDS system is not the direct cause of the failure. The root cause remains the lack of lubrication to the roller bearing at idle, a problem that affects all lifters.

How to Fix and Prevent the 5.7 Hemi Lifter Failure

This issue can be addressed with a clear, tiered strategy, moving from simple prevention for all owners to major hardware fixes for those “bulletproofing” their engine or repairing a failure.

Level 1: Maintenance & Prevention (For All Hemi Owners)

This is the cheapest and most effective way to prevent the “true” Hemi tick.

- Use High-Quality Oil: Use a high-quality, full synthetic motor oil. Brands like Pennzoil Platinum (the factory fill), Amsoil, Red Line, or Valvoline are frequently recommended in owner and mechanic forums.

- Shorten Oil Change Intervals: Do not follow the truck’s oil life monitor to 10,000 miles or more. The overwhelming expert and owner consensus is to change the oil and filter every 5,000 miles.

- Switch to 5W-30 Oil: This is the single most-discussed preventative measure. Switch from the 5W-20 specification to a full synthetic 5W-30 oil. This provides a more durable oil film and higher oil pressure at idle, directly addressing the low-RPM lubrication flaw.

- LIMIT IDLING: This is the most critical behavioral change. Avoid letting the truck warm up in the driveway for 10 minutes or sit idling for extended periods. Shut it off when possible.

Level 2: The Permanent Hardware Fix (When Repairing or “Bulletproofing”)

If the lifter failure has already occurred, simply replacing the cam and lifters with the same OEM parts will not solve the problem. The flaw is in the design, and the failure will happen again. The engine must be upgraded to address the root oiling problem.

- Upgrade the Oil Pump (The #1 Fix): This is the most important upgrade as it directly attacks the root cause (low oil volume at idle).

- The Parts:

- Mopar “Hellcat” Oil Pump: Part # 68195993AD. This is a high-volume pump standard on 6.2L Hellcat engines that is a popular, proven drop-in upgrade.

- Melling High-Volume Oil Pump: Part # M10452HV (for 2009+ 5.7L). This is an aftermarket pump specifically engineered to provide more oil volume at idle.

- The Logic: Mechanics and engineers argue that a high-volume pump is the key, not necessarily high-pressure. It is about flow (gallons per minute) at idle, not just pressure (psi).

- The Parts:

- Perform an MDS Delete:

- What it is: This is a comprehensive modification that involves a kit to physically remove all 16 lifters (including the 8 complex MDS lifters) and replace them with 16 simpler, more robust non-MDS lifters (often “Hellcat” lifters). The kit also includes plugs to block the MDS solenoid oil ports and requires a PCM tuner to disable the MDS function in the engine’s computer.

- Why do it: It removes a complex and potential failure point from the valvetrain.

- The “Bulletproof” Combo: The ultimate, permanent fix for the 5.7 Hemi valvetrain, typically done during a cam/lifter replacement, is to install an MDS Delete Kit and a High-Volume Oil Pump at the same time. This simplifies the engine mechanically and permanently fixes the oiling flaw.

- Internal Link: A full MDS delete is a popular modification.

Cost Analysis: What to Budget for Hemi Tick Repairs

Transparency about cost is critical. The “Hemi tick” can be a 3-, 4-, or 5-figure problem depending on its cause.

Visual: Repair & Prevention Cost Analysis

| Repair / Upgrade | Estimated Parts Cost | Estimated Total Cost (Parts + Labor) |

| Exhaust Manifold Repair (1 side) | $370 – $525 | $630 – $1,600 |

| Lifter/Cam Replacement (Full) | $700 – $1,500 | $4,000 – $8,500 |

| Upgrade: Melling Oil Pump | ~$213 | (Included in above labor if done at same time) |

| Upgrade: Hellcat Oil Pump | ~$210 | (Included in above labor if done at same time) |

| Upgrade: MDS Delete Kit | $400 – $950 | (Included in above labor if done at same time) |

The bottom line is stark. If the “true” lifter failure has occurred, the repair bill will likely be between $4,000 and $8,500. If the failure is prevented with a 5,000-mile 5W-30 oil change, the cost is under $100.

Other Hemi Noises (Piston Slap vs. Lifter Tick)

To be fully comprehensive, one other noise is sometimes confused with a tick: piston slap.

- Explanation: Piston slap is the sound of the piston “rocking” from side to side within the cylinder bore.

- Diagnosis: It is generally described as a “deeper, metallic” sound, not a light “tick”. Like the exhaust tick, it is most prominent when the engine is cold and in gear, and it often fades as the piston warms up and expands to fit the bore more tightly.

- Severity: The danger of mild piston slap is debated. On some engines, it is harmless. However, a loud slap is not normal and indicates excessive wear. Some owners report this noise remains even after a full camshaft and lifter replacement, confirming it is a separate, bottom-end issue.

Conclusion: Your Hemi Tick Action Plan

The 5.7 Hemi is a powerful and generally reliable engine. Its “fatal flaw” is well-understood and, most importantly, preventable. By using the right oil, changing it often, and limiting idle time, owners can ensure their Hemi provides 200,000+ miles of service.

For an owner who hears a tick, here is the final action plan:

- Start your cold engine. Do you hear a loud “tick-tick-tick” that completely disappears after 2-3 minutes of warming up? This is an exhaust manifold leak. It needs to be fixed, but there is no emergency and the engine is not in danger.

- Is your engine hot and at idle? Do you hear a new, soft “ping” or “rap” sound that wasn’t there when the engine was cold? This is the warning sign of early lifter failure.

- Your Next Steps:

- IMMEDIATELY stop all extended idling.

- Switch to a full synthetic 5W-30 oil now.

- Schedule an appointment with a trusted mechanic and specifically ask them to check the Oil Control Valve (OCV) screens for metal debris.

- Is your engine running rough and the Check Engine Light is on? This is likely the late stage of lifter failure. The engine should not be driven, as doing so is circulating metal particles and causing further damage.

Frequently Asked Questions (FAQs)

Q: What is the “real” Hemi tick?

A: The “real” or “true” Hemi tick is the sound of a failed lifter roller and damaged camshaft. This sound is a soft “ping” or “rap” that, critically, occurs when the engine is hot and at idle. It is very different from the much more common exhaust manifold tick, which is loud when cold and disappears when warm.

Q: Can I fix the Hemi tick by changing my oil?

A: If the tick is from a failing lifter, no. The mechanical damage is already done, and the bearing will not fix itself.6 However, switching to a high-quality 5W-30 synthetic oil and changing it every 5,000 miles is the single best way to prevent the tick from ever starting.

Q: What is the best oil to prevent the 5.7 Hemi tick?

A: While the factory cap may say 5W-20, many experts and high-mileage owners strongly recommend a full synthetic 5W-30 oil. Brands like Pennzoil Ultra Platinum, Amsoil Signature Series, or Red Line are often cited. The thicker viscosity provides more protection and higher oil pressure at idle, which is the root of the problem.

Q: How much does it cost to fix the 5.7 Hemi lifter and cam failure?

A: This is a major, labor-intensive repair. Owners should expect quotes from an independent shop to range from $4,000 to $8,500, and potentially higher at a dealership.

Q: Will deleting the MDS system prevent lifter failure?

A: Deleting the MDS (Multi-Displacement System) is a popular upgrade that removes the complex MDS-specific lifters. However, the root cause of failure is oil starvation at idle. The best solution, which is almost always done during an MDS delete, is to also install a high-volume oil pump (from a Hellcat or Melling) to permanently fix the oiling problem.

Q: Is it safe to drive with the Hemi tick?

A: It depends on which tick. If it is an exhaust manifold tick (loud when cold, gone when warm), it is not an emergency and will not harm the engine, though it should be fixed.11 If it is the “true” lifter tick (hot at idle), you should not continue to drive it. The failing component is sending metal fragments through your entire oil system, which can lead to complete and irreversible engine failure.

Q: What is the 5.7 Hemi lifter failure TSB?

A: There are two relevant bulletins. The most common “tick” TSB is 09-001-24, which is not for the lifters but for the exhaust manifold leak. The dealer document for the lifter/cam failure is STAR Case S1709000010, which is a diagnostic guide telling dealers to check the OCV for metal. It is important to know that Technical Service Bulletins (TSBs) are not recalls and are not covered for free once the vehicle is out of its powertrain warranty.