5.7 Hemi Rocker Arm Torque Specs

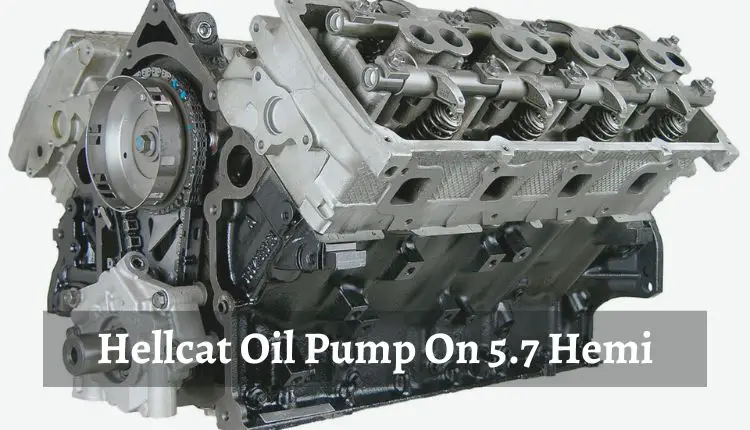

The official torque spec for a 5.7 Hemi rocker arm is 195 in-lbs. When it comes to maintaining the integrity and performance of your 5.7 Hemi engine, knowing the correct torque specifications is crucial.

Step-by-Step Guide to Torquing a 5.7 Hemi Rocker Arm

In this part, we’ll walk you through the process of properly torquing the rocker arm bolts on a 5.7 Hemi engine. Each step is designed to guide you through the process efficiently and safely.

Tools Needed for Torquing

Before you get started with the torque process, make sure you have the right set of tools.

- Torque Wrench: Essential for accurate torque measurement

- Socket Set: Specifically, a socket that fits the rocker arm bolts

Locating the Rocker Arm Bolts

First things first, locate the rocker arm bolts on your 5.7 Hemi engine. They are generally situated near the top of the engine.

Using a Torque Wrench to Tighten to 195 in-lbs

Next, grab your torque wrench and set it to 195 in-lbs. Carefully tighten the rocker arm bolts to this specification.

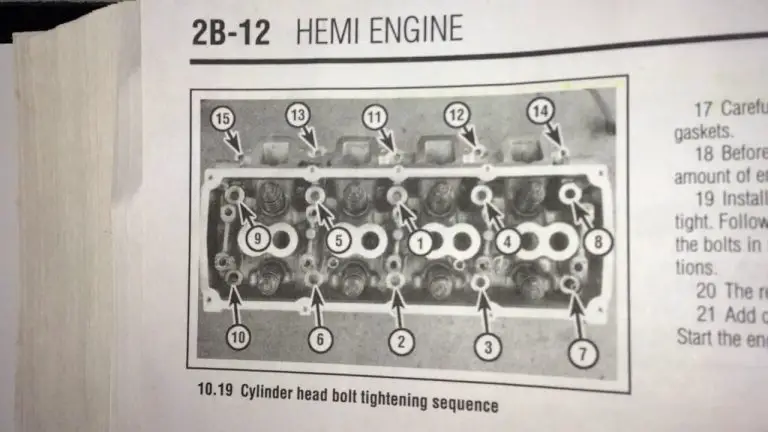

Working in a Star Pattern

Now, when tightening the bolts, it’s advisable to use a star pattern. This ensures an even distribution of pressure across the rocker’s arm.

Precautions to Avoid Over-tightening

While you’re tightening, be cautious not to go beyond the 195 in-lbs specification.

Note: Over-tightening can cause severe engine damage, including cracked or warped components.

Rechecking Torque Specs

After you’ve completed the torque process and the engine has cooled down, it’s a good idea to double-check your work.

Remember: Bolts can loosen over time, especially after the engine has gone through a heat cycle.

How Temperature Affects Torque Specifications

When it comes to maintaining your vehicle’s engine, especially something as delicate as torque specifications, temperature can be a significant but often overlooked factor. In this segment, we’ll explore the relationship between temperature and torque, and how varying temperatures can influence the torque specifications of your 5.7 Hemi engine.

Why Temperature Matters

Temperature can affect the physical properties of metals, including their ability to expand or contract. This is especially pertinent when it comes to components like bolts, which need to be torqued to specific values for optimal performance.

Note: Incorrect torque due to temperature changes can lead to engine damage or failure.

The Science Behind Metal Expansion and Contraction

Metals expand when heated and contract when cooled. This natural phenomenon is due to the molecular structure of metals and how they respond to temperature changes.

Warning: Both extreme heat and extreme cold can cause significant changes in metal dimensions, affecting torque values.

How Temperature Changes Affect the 5.7 Hemi Engine

Engines, like the 5.7 Hemi, operate under various temperature conditions. From cold starts to running at full throttle, temperature changes can affect the torque specifications of key components like the rocker arm.

Remember: Always refer to the manufacturer’s guidelines, as some engines may have temperature-specific torque specifications.

Cold Weather Impact

Cold temperatures can cause metal components to contract, making them harder and potentially leading to higher torque readings than are actually applied.

Hot Weather Impact

Conversely, hot temperatures can cause metal components to expand, making them softer and potentially leading to lower torque readings than are actually applied.

Practical Tips for Managing Torque in Different Temperatures

Here, we provide some actionable tips for maintaining correct torque specifications under varying temperature conditions.

- Calibrate Your Torque Wrench Regularly: Especially if you live in an area with significant temperature fluctuations.

- Check Manufacturer Guidelines: Some provide temperature-specific torque specs.

- Recheck Torque After Temperature Changes: If the vehicle has been subjected to extreme temperatures, it’s advisable to recheck torque specs.

Understanding how temperature impacts torque specifications can be crucial for maintaining the performance and longevity of your 5.7 Hemi engine. Being aware of this relationship allows for more accurate and reliable engine maintenance.

Read Also

5.7 Hemi Water Pump Bolt Torque Specs

5.7 Hemi Spark Plug Torque Specs

Frequently Asked Questions

What is the significance of the star pattern?

The star pattern is crucial when it comes to evenly distributing torque across the rocker arm. This prevents localized stress and ensures that all bolts are equally tightened, minimizing the risk of damaging the engine components.

How often should you check the torque specs?

Routine maintenance should include checking the torque specifications of essential engine components like the rocker’s arm. For the 5.7 Hemi, it’s recommended to check the torque specs at least once a year or during every major service interval.

Can you use an electronic torque wrench?

Yes, you can use an electronic torque wrench as long as it provides accurate measurements. They often come with additional features like digital displays and auditory signals, making the torquing process easier to manage.