6.7 Cummins Torque Specs – The Complete Guide (Output & Bolt Specs)

The 6.7L Cummins Turbo Diesel is more than just an engine; it’s a legend in the heavy-duty truck world, a benchmark for power, and the heart of the Ram 2500 and 3500’s formidable reputation.1 Since its introduction in mid-2007, it has been at the forefront of a relentless battle for towing supremacy, with its torque output serving as the primary measure of its might.3

For truck owners, mechanics, and enthusiasts, the term “6.7 Cummins torque specs” holds a dual meaning, and understanding both is critical.

- Performance Torque (Output): This is the headline-grabbing number—measured in pound-feet ($lb\text{-}ft$)—that defines the engine’s rotational force and its ability to pull heavy loads. It’s the specification that fuels the “torque wars” between Ram, Ford, and GM.

- Fastener Torque (Mechanical): This is the essential, behind-the-scenes data for mechanics and DIYers. These are the precise tightening specifications for every nut and bolt, from cylinder heads to the oil pan, ensuring the engine is assembled correctly for safe, reliable operation.

This definitive guide covers both aspects in exhaustive detail. It traces the evolution of the 6.7L Cummins’s staggering power output year by year and provides a comprehensive databank of fastener torque specifications for maintenance, repair, and high-performance builds.

The King of Torque

A Visual Guide to the 6.7L Cummins Engine’s Dominance

Since its introduction in 2007.5, the 6.7L Cummins inline-six turbodiesel has been at the center of the heavy-duty truck torque wars. Its story is one of relentless engineering, consistently pushing the boundaries of what a consumer diesel engine can produce. This infographic explores that journey, from its impressive debut to today’s staggering four-figure torque ratings, and provides critical specs for owners and mechanics.

The Relentless Climb: Torque Over The Years

The chart below visualizes the 6.7L Cummins High Output engine’s remarkable increase in torque. This steady climb represents a constant battle for towing supremacy, with major milestones like breaking the 800, 900, and eventually the 1,000 lb-ft barriers.

Today’s Power: Current 6.7L Cummins Specs

Today, Ram offers two distinct outputs for the 6.7L Cummins, allowing buyers to match the engine’s capability to their specific needs. The Standard Output (SO) provides a robust 850 lb-ft of torque, while the High Output (HO) version, paired with the Aisin transmission, delivers a class-leading 1,075 lb-ft.

This incredible output is a key differentiator in the fierce heavy-duty truck market. When deciding between models, many buyers compare the 6.7 Powerstroke vs 6.7 Cummins

, where torque figures are a primary factor.This engine has also built upon the legacy of its predecessor. You can explore a detailed breakdown of the 5.9 vs 6.7 Cummins to see just how far the platform has evolved in terms of power, emissions, and refinement.

Standard Output vs. High Output

For the Mechanic: Critical Bolt Torque Specs

Harnessing this much power requires precision. Proper torque specifications are not just recommendations; they are critical for engine longevity, reliability, and safety. Below are some of the most essential torque specs for the 6.7L Cummins. Always consult the official service manual for your specific model year before performing work.

| Component | Torque Specification |

|---|---|

| Cylinder Head Bolts (M12) | 77 ft-lbs (105 Nm), then rotate an additional 90° |

| Main Bearing Cap Bolts | 44 ft-lbs (60 Nm), then rotate an additional 90° |

| Connecting Rod Bolts | 44 ft-lbs (60 Nm), then rotate an additional 60° |

| Flywheel Bolts (Manual) | 101 ft-lbs (137 Nm) |

| Flexplate Bolts (Automatic) | 101 ft-lbs (137 Nm) |

| Exhaust Manifold Bolts | 32 ft-lbs (43 Nm) |

Data compiled from sources including Cummins Inc. and Ram Trucks. Specifications are for reference; always verify with an official service manual.

The Legend of the 6.7L Cummins: A Legacy Forged in Torque

To understand the 6.7L Cummins, one must first understand the market it dominates. In the world of heavy-duty pickups, torque is king. While horsepower determines how fast a truck can go, torque dictates how much work it can do. This focus on a single, powerful metric has fueled an engineering and marketing arms race for decades.5 When Dodge (now Ram) and Cummins first partnered in 1989, their 5.9L engine produced a respectable 400 lb-ft of torque.1 By the time the 5.9L was retired in 2007, it had reached 610 lb-ft.6

This was not enough. To compete with the ever-increasing outputs from Ford’s Power Stroke and GM’s Duramax, and to meet tightening emissions standards, a new engine was needed.3 Cummins responded by increasing both the bore and stroke of their legendary inline-six, creating the 6.7-liter (408 cubic inch) powerhouse that debuted in mid-2007.3 From its initial rating of 650 lb-ft, the 6.7L Cummins began a relentless climb, breaking the 800, 900, and eventually the once-unthinkable 1,000 lb-ft barriers.4 This progression wasn’t just about engineering prowess; it was a direct response to market demands and a declaration of dominance in the ongoing torque wars.

The Torque Wars: A Year-by-Year Evolution of 6.7L Cummins Power

The story of the 6.7L Cummins’s output is one of constant evolution, with significant updates occurring in 2013, 2019, and 2025.5 Each increase in power was the result of significant mechanical and technological advancements, from stronger internal components to more sophisticated fuel and emissions systems.

The Foundation (2007.5–2012)

The 6.7L launched with a significant power advantage over its 5.9L predecessor, boasting 350 horsepower and 650 lb-ft of torque when paired with the new 68RFE six-speed automatic transmission.3 A key trend was established immediately: the highest torque ratings were reserved for automatic transmissions. Models equipped with the Mercedes-sourced G56 manual transmission were detuned to 610 lb-ft to protect the gearbox, a practice that would continue until the manual’s discontinuation.3 The first major torque increase arrived in 2011, when Ram recalibrated the engine for 68RFE-equipped trucks to produce a massive 800 lb-ft, a 150 lb-ft jump with no change in horsepower.1

The High Output Era (2013–2018)

The 2013 model year marked a pivotal redesign. To handle even greater power, Ram introduced the ultra-durable Aisin ASC69RC six-speed automatic transmission as an option for Ram 3500 models.1 This robust gearbox enabled the creation of the first “High Output” (H.O.) variant of the 6.7L Cummins, which debuted with 385 hp and 850 lb-ft of torque.3 This period also saw the universal adoption of Selective Catalytic Reduction (SCR) technology, which uses Diesel Exhaust Fluid (DEF) to clean emissions. This aftertreatment system not only cleaned the exhaust but also allowed engineers to tune the engine for more power and efficiency.5

Throughout these years, the H.O. engine’s torque rating steadily climbed in a clear display of one-upmanship against the competition:

- 2015: 865 lb-ft

- 2016: 900 lb-ft

- 2018: 930 lb-ft

This relentless pursuit of torque was not just a numbers game; it was enabled by the capability of the Aisin transmission. The engine’s potential was directly tied to the transmission’s ability to reliably transfer that immense force to the ground. The standard output engine, still paired with the 68RFE, remained at a potent 800 lb-ft during this period.5 The G56 manual transmission was officially retired after the 2018 model year, signaling the end of an era and cementing the automatic transmission’s role as the necessary partner for extreme torque.5

Breaking the Four-Figure Barrier (2019–2024)

For 2019, Ram and Cummins unveiled the most significant redesign of the 6.7L to date, with one goal in mind: breaking the 1,000 lb-ft barrier.5 The H.O. engine was comprehensively re-engineered with a stronger and lighter compacted graphite iron (CGI) block, stronger forged connecting rods, new pistons, and an updated cylinder head.5 A new Bosch CP4.2 high-pressure fuel pump was introduced (though it would later be recalled and replaced with the more reliable CP3 in 2021) to deliver fuel at up to 29,000 psi.5 The result was a monumental 400 horsepower and 1,000 lb-ft of torque, a first for a production pickup truck.4 The standard output engine also received a boost to 370 hp and 850 lb-ft.5

The power climb wasn’t over. In 2021, a new ECU calibration pushed the H.O. model even further to its current rating of 420 horsepower and a staggering 1,075 lb-ft of torque.5

The Next Generation (2025 and Beyond)

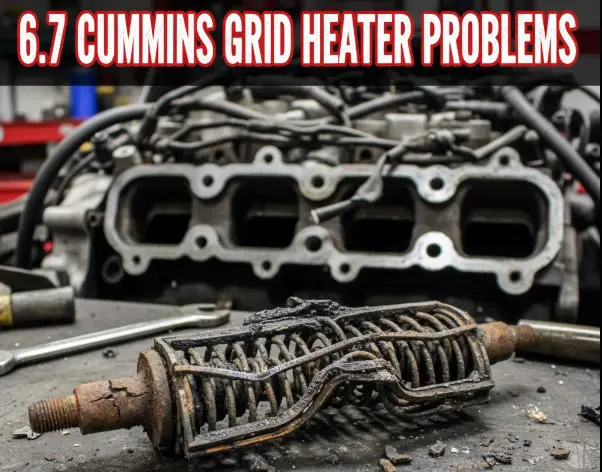

Looking ahead to the 2025 model year, Ram is streamlining its diesel offerings. The standard output engine is being discontinued for pickups, leaving a single, updated H.O. 6.7L Cummins as the sole option.5 This next-generation engine is paired with a new, highly advanced ZF PowerLine 8-speed automatic transmission, a move designed to improve driveability, efficiency, and performance.12 Key engine updates include a new Bosch CP8 fuel pump, a return to a grey cast iron block, a new cylinder head with externally mounted injectors for easier servicing, and the replacement of the grid heater with traditional glow plugs for cleaner startups.5

The table below provides a comprehensive summary of the 6.7L Cummins’s performance evolution.

Table – 6.7L Cummins Horsepower & Torque by Model Year

A chart detailing the evolution of the 6.7L Cummins engine’s horsepower and torque ratings from its introduction in 2007.5 to the latest 2025 models, broken down by engine variant and transmission type.

| Model Year(s) | Application | Engine Variant | Transmission | Horsepower | Torque (lb-ft) | Key Technical Changes |

| 2007.5–2010 | Ram 2500/3500 | Standard Output | 68RFE Auto | 350 | 650 | Engine debut; increased displacement to 6.7L; VGT turbo; DPF & EGR systems introduced 3 |

| 2007.5–2012 | Ram 2500/3500 | Standard Output | G56 Manual | 350 | 610 | Detuned for manual transmission durability 3 |

| 2011–2012 | Ram 2500/3500 | Standard Output | 68RFE Auto | 350 | 800 | First major torque increase via ECU recalibration 1 |

| 2013–2018 | Ram 2500/3500 | Standard Output | 68RFE Auto | 370 | 800 | Minor HP increase; SCR (DEF) system added for pickups 5 |

| 2013–2014 | Ram 3500 | High Output (H.O.) | Aisin Auto | 385 | 850 | H.O. model debuts with robust Aisin transmission 3 |

| 2015 | Ram 3500 | High Output (H.O.) | Aisin Auto | 385 | 865 | Minor torque increase 3 |

| 2016–2017 | Ram 3500 | High Output (H.O.) | Aisin Auto | 385 | 900 | Breaks the 900 lb-ft mark 5 |

| 2018 | Ram 3500 | High Output (H.O.) | Aisin Auto | 385 | 930 | Final year for G56 manual transmission 3 |

| 2019–Present | Ram 2500/3500 | Standard Output | 68RFE Auto | 370 | 850 | Major engine redesign with CGI block and stronger internals 5 |

| 2019–2020 | Ram 3500 | High Output (H.O.) | Aisin Auto | 400 | 1,000 | First production pickup engine to achieve 1,000 lb-ft 4 |

| 2021–2024 | Ram 3500 | High Output (H.O.) | Aisin Auto | 420 | 1,075 | HP and torque increase via new ECU calibration; return to CP3 fuel pump 5 |

| 2025+ | Ram 2500/3500 | High Output (H.O.) | ZF 8-Speed Auto | 430 | 1,075 | Engine redesign; new fuel pump, glow plugs, cast iron block; new 8-speed transmission 5 |

| 2010–2018 | Chassis Cab | Chassis Cab | Manual / Auto | 305–325 | 610–750 | Lower ratings tailored for commercial duty cycles 1 |

| 2019–Present | Chassis Cab | Chassis Cab | Aisin Auto | 360 | 800 | Power increase to align with pickup engine updates 5 |

The Mechanic’s Databank: Critical 6.7L Cummins Fastener Torque Specs

Proper engine assembly is a science that relies on precision. The correct clamping force on each fastener is essential for preventing leaks, ensuring structural integrity, and achieving long-term reliability.14 The following tables provide a comprehensive reference for the most critical fastener torque specifications for the 6.7L Cummins engine.

Disclaimer: These specifications are for reference only. Always use a calibrated torque wrench and follow the tightening sequence specified in the factory service manual for your vehicle’s exact model year. Thread condition is critical; all threads should be clean and free of debris or oil unless a specific lubricant is called for.

Many critical fasteners on the 6.7L Cummins are Torque-to-Yield (TTY) bolts. This means the specification is not a single value but a multi-step procedure involving an initial torque setting followed by a specific angle of rotation (e.g., $+90^{\circ}$). This process stretches the bolt into its elastic range to provide a very precise and consistent clamping force. TTY bolts are typically single-use and should be replaced whenever they are removed. Simply applying a final torque value without following the multi-step procedure will result in improper clamping force and potential engine failure.

Table – Core Engine Assembly Torque Specs

A detailed chart of fastener torque specifications for the main internal components of the 6.7L Cummins engine, essential for rebuilds and major repairs.

| Component | Fastener Type | Torque Specification (ft-lbs) | Torque Specification (N-m) | Notes / Sequence |

| Cylinder Head Bolts | Stock TTY Bolts | Step 1: 66 Step 2: 66 Step 3: $+90^{\circ}$ | Step 1: 90 Step 2: 90 Step 3: $+90^{\circ}$ | Follow factory sequence. Bolts are single-use.15 |

| Main Bearing Cap Bolts | New TTY Bolts | Step 1: 89 Step 2: Loosen All Step 3: 44 Step 4: 63 Step 5: $+120^{\circ}$ | Step 1: 120 Step 2: Loosen All Step 3: 60 Step 4: 85 Step 5: $+120^{\circ}$ | Follow factory sequence from center outwards. New bolts required.16 |

| Main Bearing Cap Bolts | Used Bolts | Step 1: 45 Step 2: 66 Step 3: $+90^{\circ}$ | Step 1: 61 Step 2: 89 Step 3: $+90^{\circ}$ | Follow factory sequence. Re-use is not generally recommended.17 |

| Connecting Rod Bolts | Stock TTY Bolts | Step 1: 22 Step 2: 44 Step 3: $+60^{\circ}$ | Step 1: 30 Step 2: 60 Step 3: $+60^{\circ}$ | Bolts are single-use. Lubricate threads with engine oil. |

Table – Fuel, Air, & Exhaust System Torque Specs

A chart outlining fastener torque values for common maintenance and performance upgrade areas like the fuel injectors, turbocharger, and manifolds.

| Component | Fastener Type | Torque Specification (in-lbs) | Torque Specification (ft-lbs) | Notes / Sequence |

| Injector Hold-Down Bolts | M6 Bolts | Pre-torque: 44 Final Torque: 71–89 | ~6–7.4 | Sources vary slightly on final torque. Pre-torquing seats the injector.19 |

| Injector Fuel Feed Tube | Retaining Nut | N/A | Pre-torque: 11 Final Torque: 37 | Pre-torquing seats the connector tube before final injector clamp torque.19 |

| Intake Manifold / Horn | M8 Bolts | N/A | 18 | Tighten in a crisscross pattern from the center outwards.22 |

| Exhaust Manifold to Head | M10 Bolts / Studs | N/A | 32–35 | Apply anti-seize to threads. Tighten from center outwards.24 |

| Turbocharger to Manifold | M10 Nuts | N/A | 32–46 | Torque value can vary by model year. 2021+ H.O. models may be higher.26 |

Table – Accessory & Drivetrain Component Torque Specs

A reference chart for fastener torque specifications of external engine components and drivetrain connections.

| Component | Fastener Type | Torque Specification (ft-lbs) | Notes / Sequence |

| Flywheel / Flexplate Bolts | M12 Bolts | 101 | Tighten in a crisscross pattern. Use of thread locker is recommended.28 |

| Oil Pan Bolts | M8 Bolts | 18 | Tighten in the factory-specified sequence to ensure even gasket pressure.28 |

| Oil Pan Drain Plug | Plug | 60 | For standard metal pan. Plastic pans may have a lower spec.28 |

| Rocker Arm Pedestal | M10 Bolts | 27 | Ensure pedestal is seated correctly before torquing.19 |

| Vibration Damper | M12 Bolts | 92 | Use a crankshaft barring tool to hold the engine while torquing.28 |

| Valve Cover | M8 Bolts | 18 | Tighten from the center outwards.28 |

High-Performance Upgrades: ARP Head Stud Torque Specifications

For owners who have tuned their engines for higher boost and power levels, the factory TTY head bolts can become a weak point. The increased cylinder pressure can stretch the stock bolts beyond their limit, leading to head gasket failure.3 The most common and effective solution is to replace the factory bolts with high-strength, reusable head studs from a company like Automotive Racing Products (ARP).32 These studs provide significantly higher clamping force and are essential for reliability in high-performance applications.

Proper torque on these studs is critical and requires the use of the manufacturer’s specified assembly lubricant.

Table – ARP Head Stud Torque Specs

A quick-reference guide for the torque specifications of popular aftermarket ARP head studs for the 6.7L Cummins engine.

| ARP Series | Common Part Number | Final Torque Value (with ARP Ultra-Torque Lube) | Notes |

| ARP 2000 (“425s”) | 247-4202 | 125 ft-lbs | This is the most common upgrade for moderately modified trucks. Tighten in 3 steps: 40 ft-lbs, 80 ft-lbs, then 125 ft-lbs.33 |

| ARP Custom Age 625+ | 247-4204 | 150–155 ft-lbs | For extreme high-performance and competition builds requiring maximum clamping force.32 |

Understanding the Numbers: 6.7L Cummins Torque FAQs

What’s the difference between the Standard Output and High Output 6.7L Cummins?

The High Output (H.O.) engine is a premium option, historically available only on Ram 3500 models paired with the more robust Aisin (and now ZF) automatic transmission. It features a more aggressive engine calibration to produce higher peak horsepower and torque figures.5 In some generations, like the 2019+ models, the H.O. engine also has a lower compression ratio ($16.2:1$ vs. $19:1$ for the S.O.), which allows for higher turbo boost pressures to be run safely, generating more power while managing emissions.10

How much horsepower and torque can a stock 6.7L Cummins reliably handle?

While the stock internal components like the crankshaft and connecting rods are quite robust, they are not invincible. Enthusiast communities and performance shops generally consider the stock bottom end to be reliable up to approximately 700–800 hp.36 However, other components become limiting factors long before that. The stock 68RFE transmission is a known weak point and often requires upgrades to handle even moderate power increases over stock.37 The fuel system (lift pump and injection pump) will also need to be upgraded to support power levels beyond 600 hp.36

Why does the Cummins engine produce so much torque at low RPMs?

The 6.7L Cummins’s exceptional low-end torque is a result of its fundamental design. As an inline-six engine, it features a very long piston stroke of 4.88 inches.1 This long stroke provides greater leverage on the crankshaft with each combustion event, generating significant “natural torque” without needing high engine speeds.38 This is complemented by a sophisticated Holset Variable Geometry Turbocharger (VGT). The VGT can alter its internal geometry to act like a small, quick-spooling turbo at low RPMs, building boost almost instantly. This combination results in the massive, readily available torque that gives Cummins-powered trucks their signature “pulls like a train” feel, often below 2,000 RPM.3

What are the most common engine problems related to its high torque output?

The very systems that enable the 6.7L’s high output can also be sources of common problems. The emissions equipment—particularly the Exhaust Gas Recirculation (EGR) system and the Diesel Particulate Filter (DPF)—are the most frequent cause of issues, often due to clogging from soot, especially in trucks that idle frequently or take short trips.37 The complex VGT turbo can also fail due to soot buildup causing the variable vanes to stick.37 Finally, the immense torque puts significant stress on the drivetrain. As mentioned, the stock 68RFE automatic transmission is often the first component to fail in trucks that are tuned for more power or used for heavy towing.37 For more information on common issues, you can explore our detailed guide on.