Cummins Isc 8.3 Lift Pump Location: Unveiling the Mystery

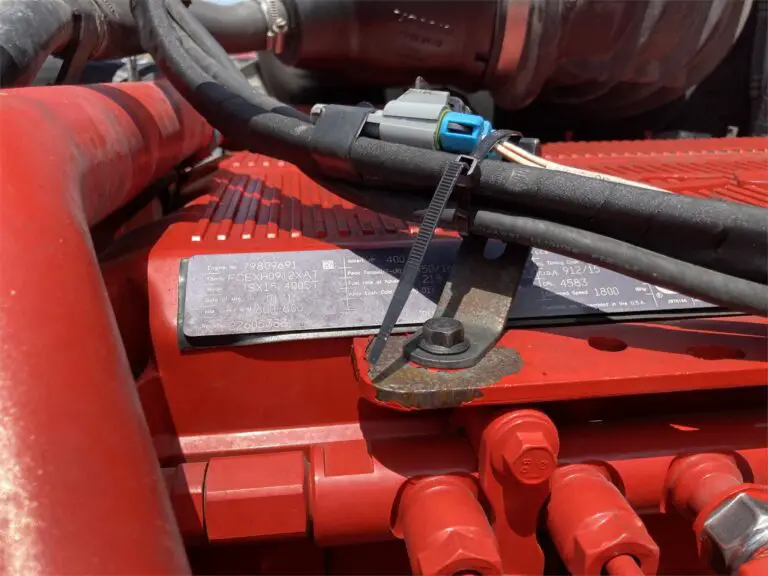

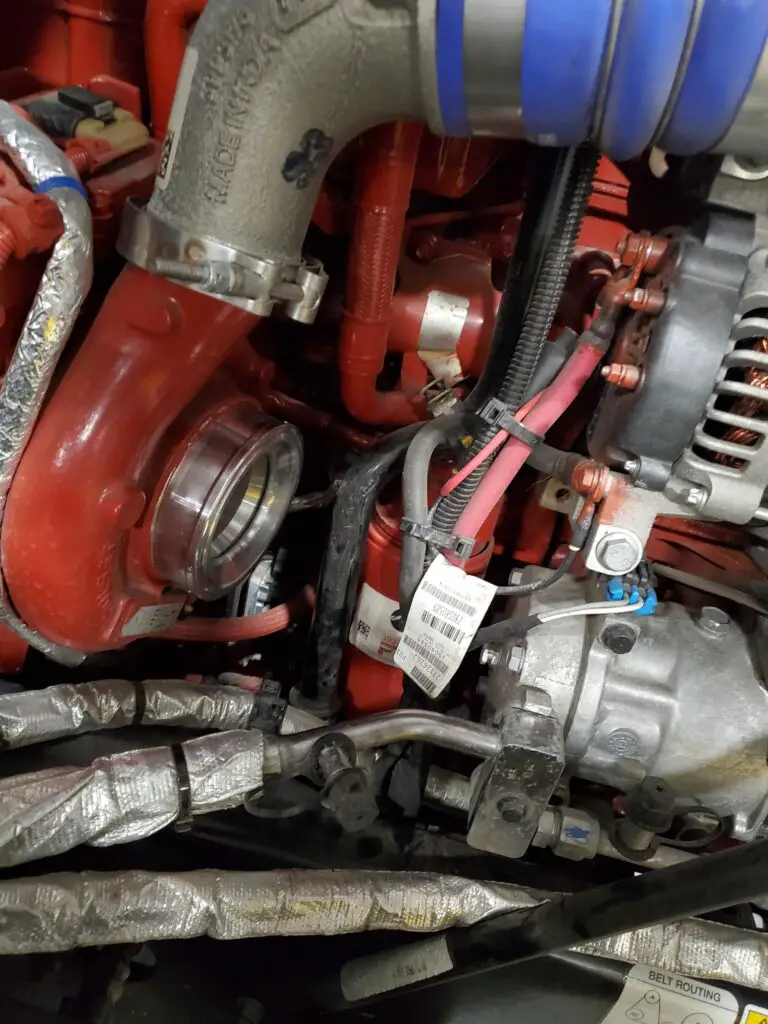

The lift pump on a Cummins ISC 8.3 engine is located on the engine, just above the starter motor. It is not recommended for inexperienced individuals to attempt the replacement of this pump as it can be a challenging task.

Where Is The Cummins Isc 8.3 Lift Pump Located?

The Cummins ISC 8. 3 lift pump is typically located on the engine, just above the starter motor. However, on pusher models, it would be on the passenger side. This electric motor-driven device is responsible for transferring fuel in the diesel system.

|

Where is the Cummins ISC 8.3 Lift Pump Located?

The lift pump on a Cummins ISC 8.3 engine is located just above the starter motor. On a pusher, this would be on the passenger side. The lift pump serves the important function of transferring fuel from the fuel tank to the engine. It is a small electric motor-driven device that is mounted either in the fuel tank or on the fuel rail, depending on the specific vehicle model. The lift pump’s position above the starter motor allows for easy access and maintenance. If you are experiencing any issues with the lift pump, it is crucial to have it checked and replaced by a professional to ensure proper engine function and performance. |

Credit: wnbf.com

How To Replace The Cummins Isc 8.3 Lift Pump?

| Step 1: Gathering necessary tools and materials |

| Step 2: Disconnecting the battery |

| Step 3: Locating and accessing the lift pump |

| Step 4: Removing the old lift pump |

| Step 5: Installing the new lift pump |

| Step 6: Testing the new lift pump |

To replace the Cummins ISC 8.3 lift pump, you need to follow these steps:

Step 1: Gather the necessary tools and materials for the replacement process.

Step 2: Disconnect the battery to ensure safety during the replacement.

Step 3: Locate and access the lift pump. On most late-model diesel vehicles, the lift pump is a small electric motor-driven device mounted either in the fuel tank or on the fuel rail.

Step 4: Remove the old lift pump carefully, ensuring not to damage any surrounding components.

Step 5: Install the new lift pump in the same location as the old one. Make sure it is securely tightened.

Step 6: Test the new lift pump to verify its proper functioning.

By following these steps, you can successfully replace the Cummins ISC 8.3 lift pump.

Signs Of A Faulty Or Failing Lift Pump

The lift pump for the Cummins ISC 8. 3 engine is located on the engine, just above the starter motor. It is a small electric motor-driven device that helps transfer fuel from the fuel tank to the engine. If you notice any signs of a faulty or failing lift pump, such as reduced engine performance or difficulty starting the engine, it may be time to replace it.

Indicators Of Lift Pump Issues In Cummins Isc 8.3 Engines

Common symptoms of a failing lift pump in Cummins ISC 8.3 engines include:

- Engine misfires

- Difficulty starting the engine

- Stalling or hesitation during acceleration

- Decreased engine performance

- Excessive black smoke from the exhaust

- Low fuel pressure

- Erratic fuel gauge readings

If you notice any of these signs, it is important to detect and replace the faulty lift pump as soon as possible to avoid further damage to the engine. A failing lift pump can result in inadequate fuel supply, which can lead to engine failure and costly repairs.

Frequently Asked Questions Of Cummins Isc 8.3 Lift Pump Location

Where Is The Lift Pump?

The lift pump is usually located either in the fuel tank or on the fuel rail of most late-model diesel vehicles. It is a small electric motor-driven device. On a Cummins engine, the lift pump is located on the engine, just above the starter motor.

What Is The Lift Pump On A Cummins?

The lift pump on a Cummins is a small electric motor-driven device mounted either in the fuel tank or on the fuel rail. It is responsible for supplying fuel to the engine. It is typically located on the engine, just above the starter motor.

On a pusher, it would be on the passenger side.

Does A 12 Valve Cummins Have A Lift Pump?

Yes, a 12 valve Cummins does have a lift pump. It is located on the engine, just above the starter motor.

Where Is The Lift Pump On A 8.9 Cummins?

The lift pump on an 8. 9 Cummins is located on the engine, just above the starter motor. On a pusher, it would be on the passenger side. It is a small electric motor-driven device.

Conclusion

To locate the lift pump on a Cummins ISC 8. 3 engine, you can find it above the starter motor, typically on the passenger side of the engine. This pump is responsible for pumping fuel from the fuel tank to the engine.

If you need to replace or repair the lift pump, it is recommended to seek professional assistance, as it can be a challenging task. Understanding the location and function of the lift pump is essential for maintaining the performance of your Cummins ISC 8.

3 engine.