6.7 Cummins Coolant Flow Diagram

A coolant flow diagram of a 67 Cummins engine illustrates the path that coolant takes through the engine’s cooling system. Understanding this diagram is crucial in maintaining optimal engine performance, preventing overheating, and reducing emissions.

In the 67 Cummins engine, the coolant flows from the water pump, through the engine, and then into the radiator, where it is cooled before returning to the engine. The thermostat regulates the temperature of the coolant, ensuring that it remains within a safe operating range.

The 67 Cummins engine is a popular choice for heavy-duty trucks and other commercial vehicles. It’s important to understand the coolant flow diagram of the engine in order to maintain optimal performance and prevent overheating.

Related Article: 6.7 Cummins Coolant Leak Passenger Side

In this guide, we’ll take a detailed look at the coolant flow diagram of the 67 Cummins engine, including the various components of the coolant system, how it works, common issues, and maintenance tips.

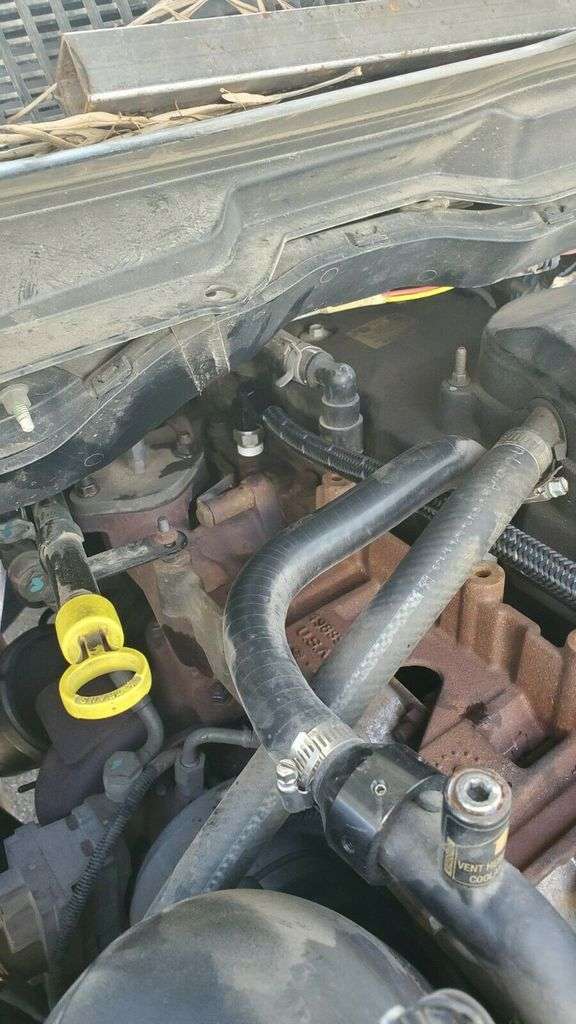

6.7L Cummins Heater Hose Rerouted

Components of the 67 Cummins Coolant System

The coolant system of the 67 Cummins engine is made up of various components that work together to regulate the engine temperature and prevent overheating. These components include:

- Water Pump: The water pump is responsible for circulating the coolant throughout the engine.

- Radiator: The radiator is designed to cool the coolant before it returns to the engine.

- Thermostat: The thermostat regulates the temperature of the coolant to ensure that it remains within a safe operating range.

- Hoses: The hoses transport the coolant to and from the engine and other components of the cooling system.

- Heater Core: The heater core is responsible for heating the air that is circulated through the cabin of the vehicle.

The Function of the Coolant System

The coolant system of the 67 Cummins engine serves several important functions:

- Regulating Engine Temperature: The coolant system helps regulate the engine temperature, preventing it from overheating or getting too cold.

- Lubricating Engine Components: The coolant helps lubricate the engine components, reducing friction and wear and tear.

- Preventing Corrosion: The coolant contains additives that help prevent corrosion and rust from developing in the engine and other components of the cooling system.

- Reducing Emissions: The coolant system helps reduce emissions by regulating the engine temperature, which in turn reduces the number of pollutants that are released into the environment.

- Check it Chevy 350 Cooling System Diagram

How the Coolant System Works in 67 Cummins Engine

Understanding how the coolant system works in the 67 Cummins engine is key to maintaining optimal performance and preventing issues. Here’s a step-by-step breakdown of how it works:

- The water pump circulates the coolant throughout the engine.

- As the coolant passes through the engine, it absorbs heat from the engine components.

- The heated coolant then flows into the radiator, where it is cooled by air that passes over the radiator fins.

- The cooled coolant then returns to the engine to absorb more heat and continue the cycle.

- The thermostat regulates the temperature of the coolant by opening and closing depending on the temperature of the coolant.

Common Coolant System Issues

There are several common issues that can arise with the coolant system of the 67 Cummins engine. These include:

- Leaks: Leaks can occur in the hoses, radiator, water pump, and other components of the cooling system, leading to low coolant levels and overheating.

- Blockages: Blockages in the hoses or radiator can prevent the coolant from flowing properly, leading to overheating and engine damage.

- Overheating: Overheating can be caused by a variety of issues, including low coolant levels, a malfunctioning thermostat, or a blocked radiator.

- Corrosion: Corrosion can occur in the engine and other components of the cooling system over time, leading to leaks and other issues.

Maintenance and Repair Tips

To keep the coolant system of the 67 Cummins engine in good condition, it’s important to perform regular maintenance and make any necessary repairs. Here are some tips to help you maintain and repair the coolant system:

- Check Coolant Levels: Regularly check the coolant levels in the radiator and top up as needed. Be sure to use the correct type of coolant for your engine.

- Flush the System: Over time, debris and other contaminants can build up in the cooling system, which can lead to blockages and other issues. It’s recommended to flush the system every 30,000 miles to remove any buildup.

- Replace the Thermostat: If your engine is overheating or not reaching the correct operating temperature, the thermostat may need to be replaced. This is a relatively simple and inexpensive repair that can prevent more serious issues down the line.

- Replace Worn Hoses: Hoses can become brittle and cracked over time, which can lead to leaks and other issues. Check the hoses regularly and replace any that show signs of wear and tear.

- Check for Leaks: Regularly inspect the cooling system for leaks, including the radiator, water pump, and hoses. If you notice any leaks, have them repaired as soon as possible to prevent further damage.

- Keep the Radiator Clean: A dirty radiator can prevent air from flowing over the cooling fins, which can lead to overheating. Keep the radiator clean by washing it with a hose or pressure washer.

- Address Corrosion: If you notice any signs of corrosion in the engine or other components of the cooling system, it’s important to address the issue as soon as possible. Corrosion can lead to leaks and other serious issues if left unchecked.

Credit: bullseyepower.com

FAQs

What is a coolant flow diagram for the 67 Cummins engine?

Why is it important to understand the coolant flow diagram of the 67 Cummins engine?

How does the coolant system work in the 67 Cummins engine?

Where it is cooled before returning to the engine to repeat the cycle. The thermostat regulates the temperature of the coolant to ensure it remains within a safe operating range.

What are some common issues that can arise with the coolant system in the 67 Cummins engine?

How often should the coolant system be flushed and maintained in the 67 Cummins engine?

Can I repair the coolant system on my own or should I take it to a professional?

Heater core coolant elbow leak fix 6.7 Cummins

Conclusion

Understanding the coolant flow diagram of the 67 Cummins engine is crucial to maintaining optimal performance and preventing issues. By understanding the various components of the cooling system,

How it works, and how to maintain and repair it, you can keep your engine running smoothly for years to come. Don’t neglect your engine’s cooling system – it’s an important part of keeping your vehicle on the road and running smoothly.

Read Also: