6.7 Cummins Fuel Rail Pressure at Idle: Boost Your Engine’s Performance

The fuel rail pressure at idle for a 6.7 Cummins engine should be within the normal operating range specified by the manufacturer. It is important to ensure that the pressure is not too high or too low, as this can result in engine performance issues.

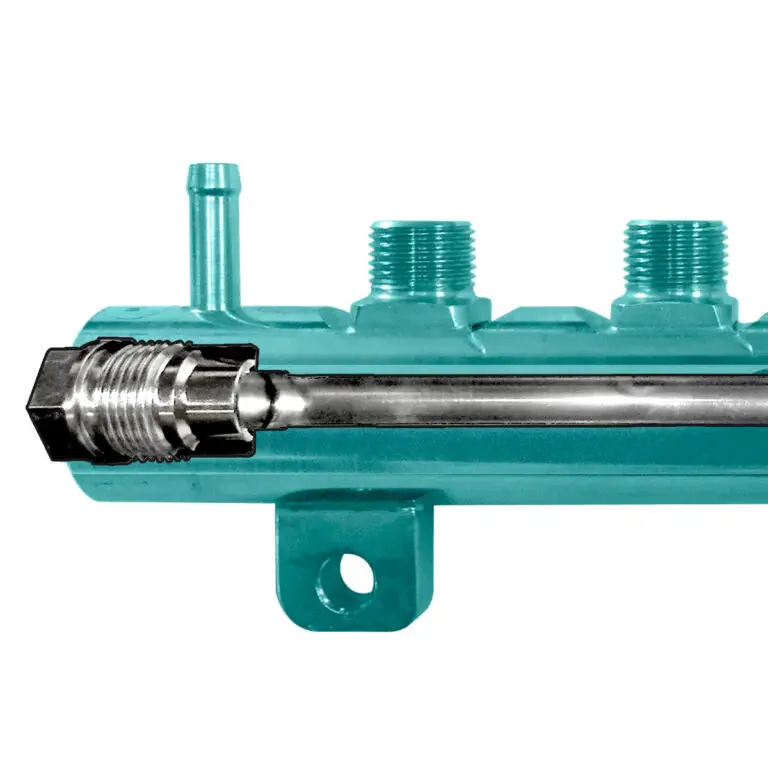

Credit: www.amazon.com

Why Idle Fuel Rail Pressure Matters

Idle fuel rail pressure is an important factor that affects the performance of 6.7 Cummins engines. The fuel rail pressure at idle directly impacts the engine’s ability to start smoothly and respond to throttle inputs consistently. If the fuel rail pressure sensor is not reading correctly, it can lead to hard starts, no starts, or inconsistent throttle response. Therefore, if you experience any of these symptoms, it is recommended to replace the failed sensor with a genuine Cummins Replacement Rail Pressure Sensor.

Understanding the relationship between idle RPM and fuel rail pressure is also crucial. Excessive or fluctuating rail pressure at idle may indicate issues with the fuel system, such as clogged injectors or fuel pump problems. On the other hand, too low rail pressure at idle can result in poor engine performance and hesitation.

Note: Proper fuel rail pressure at idle is essential for the smooth functioning of a 6.7 Cummins engine, and any deviations should be addressed promptly.

Symptoms Of Low Idle Fuel Rail Pressure

Symptoms of low idle fuel rail pressure include hard starts and no starts, inconsistent throttle response, reduced engine power, and rough idling at idle RPM. If you are experiencing any of these symptoms, it could indicate a problem with your Cummins fuel rail pressure. It is important to address this issue promptly to avoid further damage to your engine. One possible solution is to replace your failed sensor with a genuine Cummins Replacement Rail Pressure Sensor. This sensor is crucial as if it is not reading correctly, it can lead to the symptoms mentioned above. By using a genuine replacement, you can ensure a proper fit and accurate readings for optimal engine performance.

Causes Of Low Idle Fuel Rail Pressure

Low idle fuel rail pressure can be caused by several factors. One possible cause is a faulty rail pressure sensor. If this sensor is not reading correctly, it can lead to hard starts, no starts, or inconsistent throttle responses. In such cases, it is recommended to replace the failed sensor with a genuine Cummins Replacement Rail Pressure Sensor.

Clogged fuel injectors can also contribute to low idle fuel rail pressure. When the fuel injectors are clogged, they may not deliver the required amount of fuel to the engine, resulting in low pressure.

Another potential cause of low idle fuel rail pressure is a fuel pump malfunction. A malfunctioning fuel pump may not generate enough pressure to supply fuel to the engine, leading to low idle pressure.

Air leaks in the fuel system can also result in low idle fuel rail pressure. If there are any leaks in the fuel system, air can enter the system and disrupt the proper fuel flow, ultimately leading to lower pressure levels.

Addressing these causes and ensuring proper functioning of the rail pressure sensor, fuel injectors, fuel pump, and fuel system can help resolve low idle fuel rail pressure issues.

How To Measure Idle Fuel Rail Pressure

In order to measure idle fuel rail pressure on a 6.7 Cummins engine, you will need to use a fuel pressure gauge. First, you will need to locate the fuel rail pressure sensor on the engine. This sensor is responsible for monitoring the pressure in the fuel rail. Once you have located the sensor, you can begin the process of measuring the idle fuel rail pressure. Start by attaching the fuel pressure gauge to the fuel rail. Make sure the gauge is securely attached to prevent any leaks. Next, start the engine and let it idle. The fuel pressure gauge will display the current pressure in the fuel rail. Take note of this reading. The ideal idle fuel rail pressure for a 6.7 Cummins engine is typically around 5,000 to 8,000 psi. If the pressure is outside of this range, it may indicate a problem with the fuel system that requires further investigation.

Normal Idle Fuel Rail Pressure Range

| Blog Post Title: | 6.7 Cummins Fuel Rail Pressure at Idle |

|---|---|

| Heading: | Normal Idle Fuel Rail Pressure Range |

Understanding the acceptable range for idle fuel rail pressure is crucial for optimal engine performance. The recommended fuel rail pressure for most Cummins engines at idle falls within the range of 5,000 to 8,000 PSI (pounds per square inch). If the idle fuel rail pressure consistently falls below this range, it could indicate potential issues such as a faulty fuel pressure sensor or an insufficient fuel supply. On the other hand, excessively high idle fuel rail pressure could point to problems like a clogged fuel filter or a malfunctioning fuel pressure regulator.

It is important to note that the specific acceptable range may vary depending on the Cummins engine model and any modifications made to the fuel system. Consulting the engine manufacturer’s specifications or seeking guidance from a qualified diesel mechanic can help determine the appropriate fuel rail pressure range for your particular engine. Regular monitoring of idle fuel rail pressure and addressing any deviations promptly can help ensure smooth engine operation and prevent potential damage.

Tips For Boosting Idle Fuel Rail Pressure

Boosting idle fuel rail pressure is crucial for the proper functioning of your 6.7 Cummins engine. Cleaning clogged fuel injectors is the first step to take. Over time, fuel injectors can accumulate deposits that restrict fuel flow and decrease pressure. A thorough cleaning will improve fuel delivery and increase idle rail pressure.

If cleaning the injectors doesn’t solve the issue, you might need to consider replacing the fuel pump. A faulty or worn-out fuel pump can cause a drop in fuel pressure at idle. Replacing it with a new one will ensure optimal performance and boost idle fuel rail pressure.

Another potential cause of low idle fuel rail pressure is air leaks in the fuel system. Check all the connections, fittings, and hoses for any signs of leakage. Fixing any air leaks will prevent fuel pressure loss and help increase idle rail pressure.

Upgrading the rail pressure sensor is also worth considering. A malfunctioning sensor can provide incorrect readings, leading to fuel pressure problems. Upgrading to a higher-quality sensor will provide accurate measurements and improve idle fuel rail pressure.

Frequently Asked Questions Of 6.7 Cummins Fuel Rail Pressure At Idle

What Is The Normal Rail Pressure For A 6.7 Cummins?

The normal rail pressure for a 6. 7 Cummins engine is around 15,000 to 18,000 PSI at idle.

What Should Diesel Rail Pressure Be At Idle?

The diesel rail pressure at idle should be within normal specifications for your specific vehicle. It is recommended to consult your vehicle’s manual or contact a certified mechanic for accurate information.

What Is The Pressure On The Common Rail Cummins Fuel Rail?

The pressure on the common rail Cummins fuel rail varies depending on the engine’s operating conditions. However, at idle, the normal fuel rail pressure is typically around 5,000 to 25,000 PSI. It is important to ensure that the pressure is within the recommended range for optimal engine performance.

What Are The Symptoms Of The Fuel Rail Pressure Sensor On A 6.7 Cummins?

If the fuel rail pressure sensor on a 6. 7 Cummins is not working properly, you may experience symptoms like hard starts, no starts, or inconsistent throttle response. If you are experiencing these issues, replace the sensor with a genuine Cummins Replacement Rail Pressure Sensor.

Conclusion

The fuel rail pressure at idle is an important factor to consider when troubleshooting a diesel engine. If the pressure is not reading correctly, it can lead to hard starts, no starts, or inconsistent throttle response. To ensure optimal performance, it is recommended to replace any failed rail pressure sensors with genuine Cummins Replacement Rail Pressure Sensors.

By monitoring and maintaining the correct fuel rail pressure at idle, you can prevent potential issues and keep your engine running smoothly.