5.3 Valve Cover Torque Specs

The torque specs for the valve cover of a 5.3 engine depend on the manufacturer’s specifications and design. Generally, the bolts should be tightened to between 7-9 foot pounds (ft lbs) or 10-12 Newton meters (Nm). It is important to make sure that all bolts are evenly torqued when tightening them in order to ensure even clamping force which will help prevent gasket leakage.

Additionally, it is recommended that an anti-seize compound be applied before installation as this has been proven to reduce friction and increase bolt life. After assembly, it is also important to check all nuts/bolts at least once per year in order to maintain proper torque levels and prevent future leaks or damage caused by overtightening or undertightening of components.

The 5.3 valve cover torque specs are an important part of engine maintenance and should be used when replacing the valve cover gaskets. It is recommended that you use a torque wrench to ensure the correct amount of force is applied when tightening the bolts, as over-tightening them can damage both the bolt threads and gasket surfaces. The factory specification for these bolts is 10 ft/lbs (132 in/lbs), although some aftermarket covers may require greater or lesser amounts of torque depending on their construction materials.

Additionally, it’s always good practice to make sure all bolts are tightened evenly so they don’t cause any leakage or damage down the road.

Torque Spec for Valve Covers

What Do You Torque Ls Valve Covers To?

When it comes to torquing LS valve covers, there are a few things you need to consider. Generally, the torque specification for LS valve cover bolts is 8-10 ft/lbs. It’s important to use a good quality torque wrench when tightening these bolts and use only the specified amount of torque – over tightening can lead to problems with gaskets or other components.

Additionally, make sure each bolt is tightened evenly in order for optimal performance and no leaks. The best way to ensure this is by doing it in a crisscross pattern – starting at one corner, tighten one bolt then move diagonally across the surface until all of them have been properly tightened. Finally, some aftermarket parts may require different torque specs so be sure to double check your specific part before beginning any work.

What is the Torque on Valve Cover Bolts?

When performing maintenance on a vehicle, it is important to understand the torque of the valve cover bolts. Torque is defined as a measure of rotational force. It represents how much force must be applied to move a given object, in this case the valve cover bolts.

The amount of torque required for these bolts varies from one make and model to another, so it’s always important to consult your owner’s manual or an experienced mechanic before tightening them down. Generally speaking however, most vehicles require between 10-12 ft/lbs (13-16 Nm) when torquing their valve cover bolts. It’s also important not to over tighten them since doing so can cause permanent damage to the engine block and sealing surfaces which could lead to costly repairs in the future!

How Much Torque Does a 5.3 Vortec Have?

The 5.3L Vortec engine produces up to 325 lb-ft of torque at 4,400 RPM when equipped with the 3.73 axle ratio. The engine also generates up to 285 hp and a maximum of 305 lb-ft of torque when paired with a 4.10 axle ratio, allowing it to deliver plenty of power for even the most demanding applications. Its lightweight aluminum cylinder heads allow air flow that increases horsepower while helping reduce fuel consumption and emissions, making this engine an excellent choice for vehicles seeking both performance and efficiency.

In addition, its cast iron block helps ensure long lasting durability in harsh conditions while still providing quick starts and smooth acceleration all year round. All in all, the 5.3L Vortec is truly an impressive piece of engineering that delivers remarkable power along with good fuel economy numbers – perfect for those who demand peak performance from their engines!

How Many Head Bolts Does a 5.3 Have?

The 5.3-liter V8 engine is a popular choice when it comes to replacing or rebuilding an engine in your vehicle. When rebuilding the engine, one of the most important parts you will need to consider are the head bolts. The number of head bolts that come with a 5.3-liter V8 engine can vary depending on the specific model and year but generally they range from 16 to 18 individual bolts per cylinder head.

It’s important to use only new replacement head bolts as these are designed for torque specs that match your particular application and must be torqued properly in order for them to work safely and reliably over time. Be sure you have all the correct size and type of bolt before beginning so you don’t run into any issues during installation or later down the line with performance or safety concerns due to incorrect fasteners being used.

Credit: www.ls1howto.com

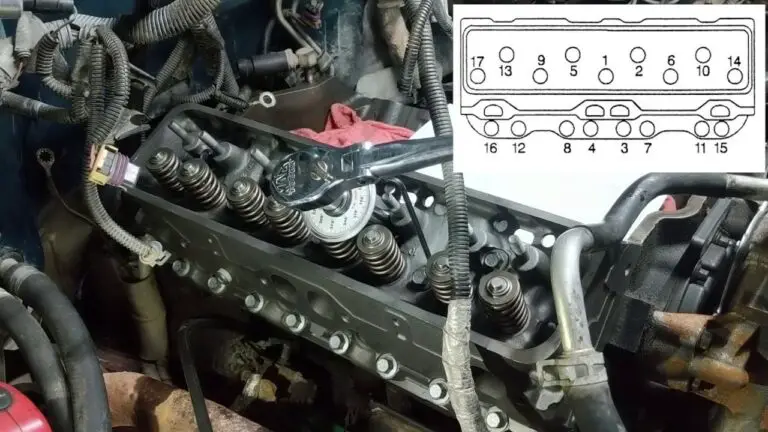

Ls Valve Cover Torque Sequence

When replacing the valve cover on an LS engine, it is important to be aware of the proper torque sequence. The recommended torque pattern for tightening a valve cover gasket is as follows: Start at one corner and work your way around in a cross-pattern, alternating sides until all bolts are tightened evenly with even pressure. Torque each bolt to 10 Nm (7 lb-ft) or use manufacturer’s specified torque settings if available.

Be sure to double check that all bolts are tight before operation and take note of any leaks from improper installation.

5.7 Vortec Valve Cover Torque Specs

The 5.7 Vortec engine is extremely popular and many people are curious about what the valve cover torque specs should be for this model. The general rule of thumb is to use a torque wrench to tighten the valve cover bolts to 10-15 ft/lbs, however it’s always best to refer to your vehicle’s specific manufacturer manual for exact specifications. Additionally, you should make sure that all bolts are tightened in a “star pattern”, which means they should be tightened gradually in a radial motion from one side of the valve cover to another.

4.8 Valve Cover Torque Specs

When tightening the 4.8 valve cover bolts, it is important to use the correct torque specs. The proper torque spec for the 4.8 valve cover bolts is 10 Nm (7 lb-ft). This torque spec should be applied in a star pattern, alternating between each bolt until all are tight and secure.

Failure to do so could lead to oil leaks or other engine problems down the road.

Conclusion

In conclusion, the 5.3 valve cover torque specs are critical to getting the job done right. It is important to consult your car’s manual for specific instructions and tighten each bolt in a crisscross pattern using a torque wrench with accurate readings. Taking the time to properly install new valve covers will help ensure that your engine operates optimally and efficiently for years to come.