Gen 4 5.3 Torque Specs

The Gen 4 5.3 torque specs are as follows: Main cap bolts – 75 ft-lbs; Connecting Rod Bolts – 18 ft-lbs; Cylinder head bolts (1st pass) – 25 ft-lbs, (2nd pass) – 50 ft-lbs + 90° rotation; Camshaft sprocket bolt – 34 ft-lbs + 180° rotation. Other specifications include the following: Intake manifold bolts/studs – 10 mm = 22 in-lb, 12mm = 33 in-lb; Exhaust manifold nuts/bolts – 13 mm = 44 in lb and 15 mm = 76 in lbs respectively. Oil pan bolts should be tightened to 9 Nm or 6ft lbs of torque and water pump to 8 Nm or 6ft lbs of torque.

The crank pulley bolt should be tightened to 150 Nm or 110ft lbs of torque while the Harmonic balancer bolt must be secured at 175 Nm or 129ft lbs of torque. Finally, the flywheel/flexplate bolts must be set at 48Nm or 35ft lbs of torque for proper installation and operation.

When it comes to the Gen 4 5.3 engines, torque specs are especially important for maintenance and repair. Torque specs provide a baseline of how much force is needed to properly secure bolts and nuts in place when assembling engine components. Knowing the proper torque spec can help prevent issues such as fastener failure or stripped threads that could potentially cause catastrophic damage down the road.

It’s always best practice to use a calibrated torque wrench whenever performing repairs on your Gen 4 5.3 engine to ensure everything is installed correctly and securely!

LS HEAD TORQUE SPECS / SEQUENCE for 4.8 5.3 5.7 6.0 6.2 7.0 ls1 ls2 ls3 ls6

What is the Torque Specs on a Ls Engine?

When it comes to torque specs on a LS engine, they will vary depending on the specific model you are working with. Generally speaking, most LS engines have a maximum torque rating of between 400 and 500 foot-pounds. However, some models can reach up to 600 foot-pounds or more.

The exact specs for your particular engine should be available in your vehicle’s owner’s manual or from the manufacturer directly. It is important to note that all engines require regular maintenance and inspection to ensure proper performance, as well as adhering strictly to the correct torque specifications when installing new parts such as connecting rods or head bolts. Failing to do so could result in severe damage leading ultimately to costly repairs down the road.

If you take care of your LS engine properly and follow these guidelines then you will maximize its potential for reliable performance over many years of use!

What is the Torque Specs for Ls Head Bolts?

The torque specs for LS head bolts is very important to know when completing any engine repair or maintenance on an LS series engine. The correct torque specification for the head bolts depend on a few factors including the type of fastener being used, cylinder head material, and year of manufacture. Generally speaking, most LS-series engines require between 30-35 ft/lbs of torque when using stock hardware and ARP hardware requires 45-50 ft/lbs.

It is always recommended to refer to the vehicle’s service manual or other reliable sources before beginning any repairs as some models may have slightly different requirements depending on their specific design features. Additionally, it’s important to note that not all head bolt threads are created equal so it is important to use lubricant such as oil or anti seize when torquing down your bolts as this will help ensure proper thread engagement and prevent galling or seizure. Following these guidelines can help ensure you get a good seal every time so you can keep your car running smoothly for years to come!

How Much Torque Does a L98 Cylinder Head Have?

When it comes to the torque of an L98 cylinder head, it depends on a few factors. The most important factor is the camshaft profile that you choose for your engine build. Generally speaking, when selecting a camshaft with a higher lift and longer duration, more torque can be generated by the cylinder heads.

This is because these cams will create a larger valve opening area at peak lift which allows more air and fuel into the combustion chamber resulting in greater power output. Additionally, other components such as valves, pistons, connecting rods and intake manifolds also contribute to how much torque can be made from an L98 cylinder head. It’s important to note however that some aftermarket performance parts may require special tuning or modifications in order to reach their full potential when used with this type of engine block.

In any case, depending on these various factors mentioned above an L98 cylinder head should typically have around 350-400 ft/lbs of torque available for use during normal driving conditions.

What are the Torque Specs?

Torque specifications, also known as torque specs, are a set of guidelines used to ensure that the correct amount of torque is applied when tightening or loosening fasteners. These torque specs are usually expressed in either foot-pounds (ft-lbs) or Newton meters (Nm). The proper amount of torque should be applied to any fastener during installation in order to ensure optimal performance and longevity.

Torque specs can vary significantly depending on the application and may even vary within the same application depending on the type of fastener being used. If an incorrect amount of torque is applied it could result in improper seating, reduced clamp load, accelerated thread wear and possibly failure due to inadequate preload. It’s therefore important to always refer to the manufacturer’s recommended torque specification before installing any hardware component.

As a general rule once a bolt has been tightened you should never attempt to re-tighten it again unless instructed by the manufacturer as this can lead to over tightening which will reduce bolt life and increase chances for failure due excessive stress loading on threads or other components in close proximity.

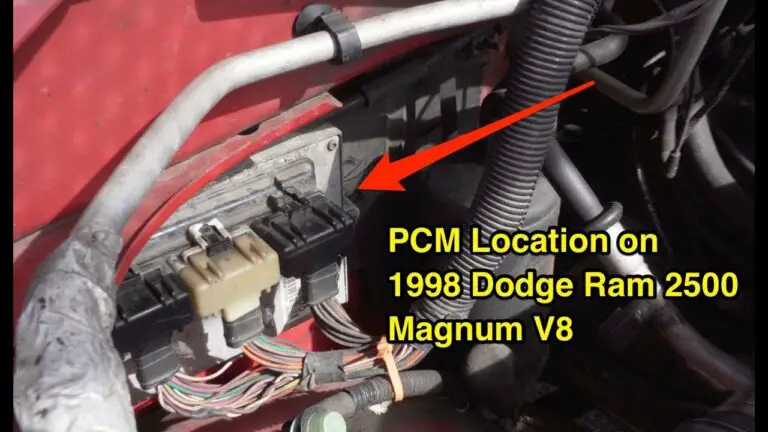

Credit: www.youtube.com

Gen 4 5.3 Head Bolt Torque Specs

The Gen 4 5.3 head bolt torque specs require that all bolts be tightened in three steps: the first step requires a torque of 30 ft-lbs, the second step requires 40 ft-lbs and the third step needs to be tightened to 50ft-lbs of torque. It’s important to use a calibrated torque wrench for proper installation and ensure that all fasteners are properly lubricated before tightening them.

Gen 4 Ls Torque Specs

When replacing or rebuilding a Gen 4 LS engine, it is important to use the correct torque specs. Depending on the application, these values can range from 9-18 foot pounds for main cap bolts and 18-30 foot pounds for head bolts. It is also important to check your vehicle’s service manual for additional torque specifications specific to your model of car.

5.3 Single Bolt Cam Torque Specs

When tightening the single bolt cam, it’s important to use the correct torque specifications. The ideal torque for this application is 12-15 ft/lbs of force. Make sure you tighten the Cam evenly and do not overtighten as this can cause damage or even breakage of parts that are connected to it.

Conclusion

In conclusion, the Gen 4 5.3 Torque Specs provides a comprehensive overview of the specifications for torque measurements on this engine model. It serves as an invaluable resource for anyone needing to ensure their vehicle is properly maintained and functioning at its best. With this information, owners can have peace of mind that their vehicles are safe and reliable when it comes to performance and durability.