Cummins Isx Bad Turbo Actuator Symptoms

A bad turbo actuator in a Cummins ISX engine may cause several symptoms. These include reduced power, black smoke coming from the exhaust, excessive fuel consumption, excessive oil consumption and increased operating temperature. The vehicle may also struggle to accelerate or reach its maximum speed limit due to poor air intake caused by the faulty actuator.

In addition, it is likely that there will be an unusual noise coming from the engine which can indicate that something is wrong with the turbocharger system. Other signs of a defective turbo actuator are white smoke being emitted when revving up the engine and strange vibrations while driving at high speeds. If any of these symptoms are present then it is advisable to get the problem checked as soon as possible to avoid further damage or costly repairs if left unchecked for too long.

The most common symptoms of a bad turbo actuator on Cummins Isx engines are poor performance, black smoke from the exhaust, and a decrease in fuel efficiency. If your engine is producing black smoke when you accelerate, it could be due to an issue with the turbo actuator. Additionally, if your RPMs increase without any improvement in acceleration or speed, this could be indicative of a faulty turbo actuator as well.

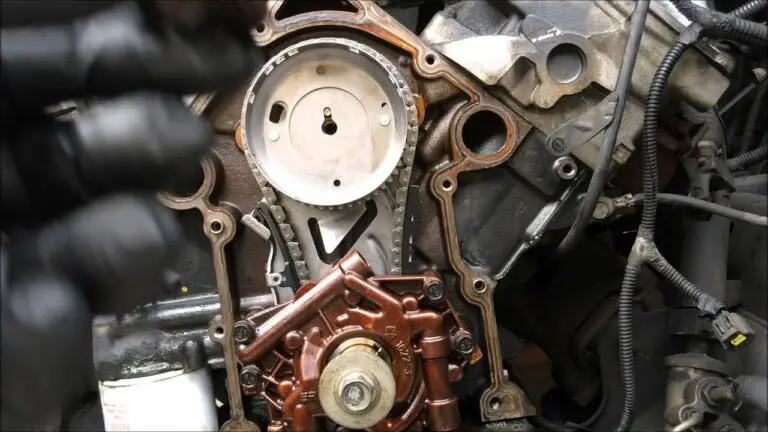

How to check if Turbo and/or Actuator is bad on Cummins ISX

How Do I Know If My Turbo Actuator is Bad?

If your vehicle is equipped with a turbocharger, it’s important to make sure that the turbo actuator is in good working order. When a turbo actuator malfunctions or fails completely, the consequences can be severe: from reduced engine performance to complete engine failure. So how do you know if your turbo actuator is bad?

There are several tell-tale signs that indicate an issue with the part. One of them would be increased exhaust smoke coming out of your tailpipe; this could mean that there’s too much pressurized air entering into your cylinders and not enough being released through the exhaust system. Other symptoms may include rough idling or hesitant acceleration when pressing down on the gas pedal; these issues occur because without proper pressure regulation, air enters into and exits out of your combustion chamber at uneven rates.

Last but not least, you may hear whistling noises coming from underhood – this indicates something is wrong with either one or both blades of the turbine wheel inside your turbo charger unit due to faulty control by its regulating device (the turbo actuator). If any of these problems arise, it’s best to get it checked out immediately as prolonged use can cause further damage to other components in your engine bay.

What are the Symptoms of a Bad Turbo in a Cummins Isx?

A bad turbo in a Cummins ISX can cause many issues, from poor fuel economy to lack of power. Common symptoms of a faulty turbo include excessive exhaust smoke, reduced engine acceleration and power, increased oil consumption, unusual noises coming from the engine bay or exhaust system and an illuminated check engine light. Other signs may include excessive vibration in the cab caused by the turbocharger or a decrease in overall engine performance and responsiveness when accelerating.

If you experience any of these symptoms with your Cummins ISX it’s important that you have it checked out immediately by a certified mechanic as they will be able to diagnose if there is an issue with the turbocharger.

Can You Still Drive With a Bad Turbo Actuator?

No, you cannot drive with a bad turbo actuator. When a turbocharger’s actuator malfunctions, it can cause the engine to run rough and lose power. This is because the turbocharger isn’t able to properly adjust its boost pressure in order to maximize engine performance.

The faulty actuator can also cause excessive exhaust smoke, as well as vibrations or rattling noises coming from the engine bay that are especially noticeable when accelerating. Furthermore, if left unchecked this issue can lead to irreparable damage done not only to your vehicle but also to components such as pistons and valves due to extreme temperatures generated by an improperly functioning turbo system. That being said, it’s important for any driver experiencing issues related to their car’s turbocharger system should have it inspected by a qualified technician at their earliest convenience in order prevent further complications down the line.

What Causes Cummins Turbo Actuator Failure?

The Cummins turbo actuator is a critical component of the turbocharger system, and it can fail due to several reasons. The most common cause of failure is wear and tear on the internal components, which can be caused by high temperatures or lack of lubrication. Another cause could be a build-up of carbon deposits in the unit, which may prevent normal operation.

Poor maintenance practices such as failing to replace worn out parts in time can also lead to early failure. In addition, improper installation or use of non-original replacement parts can also result in premature actuator failure as they are not designed for this purpose. Finally, an electrical short circuit within the control module or wiring harness can also lead to malfunctioning of the Cummins Turbo Actuator.

Credit: dieselengineparts.highwayandheavyparts.com

Cummins Isx Turbo Actuator Delete

Cummins ISX Turbo Actuator Delete is a popular mod for diesel trucks equipped with Cummins ISX engines. This modification removes the electronic turbo actuator, allowing for greater control over engine boost and more efficient use of fuel. The delete also eliminates any potential issues that may arise from the turbo actuator, such as sticking or failing to respond properly to commands.

In addition, this modification can help improve overall performance by providing increased airflow and power output.

6.7 Cummins Bad Turbo Actuator Symptoms

An unreliable turbo actuator can cause a variety of issues with your 6.7 Cummins engine, including reduced power output, excessive smoke from the exhaust pipe, and increased fuel consumption. Other symptoms include loud noises coming from the turbocharger when accelerating or during idling, as well as surging/hunting at idle speeds. If you experience any of these issues with your 6.7 Cummins engine, it may be time to have your turbo actuator inspected by a qualified technician.

Cummins Isx Actuator Problems

Cummins Isx actuator problems can be caused by several different issues, from faulty wiring to mechanical failure. Common symptoms of a problematic Cummins Isx actuator include poor fuel economy, stalling or missing during acceleration, and power loss. If you’re experiencing any of these issues with your Cummins Isx engine, it’s important to diagnose the problem and repair the issue as soon as possible in order to keep your vehicle running efficiently.

Conclusion

In conclusion, the Cummins Isx Bad Turbo Actuator Symptoms can range from a decrease in power to strange noises coming from your engine. If you experience any of these symptoms, it is important to get your vehicle checked out as soon as possible. A malfunctioning turbo actuator can have serious implications for both your car and your wallet if not addressed quickly.