Cummins ISX EGR Temperature Sensor Location: Unveiling the Power Within

The coolant temperature sensor on a Cummins ISX engine is located on top of the thermostat housing, behind the outlet hose. This sensor is responsible for monitoring the temperature of the coolant.

The Cummins ISX engine is a widely used diesel engine known for its power and reliability. Like any engine, it relies on various sensors to ensure proper functioning. One important sensor is the coolant temperature sensor, which plays a crucial role in monitoring the temperature of the coolant.

By understanding the location of this sensor, it becomes easier to troubleshoot any issues related to coolant temperature. We will discuss the exact location of the coolant temperature sensor on the Cummins ISX engine, giving you the information you need to effectively maintain and diagnose any problems with your engine.

: Unveiling The Importance Of Egr Temperature Sensor

The EGR temperature sensor plays a crucial role in the Cummins ISX engine. It is responsible for monitoring the temperature at various locations within the engine, contributing to its overall performance and efficiency. The location of the coolant temperature sensor, which is one of the key temperature sensors, can be found on top of the thermostat housing and behind the outlet hose.

A bad EGR valve can lead to several symptoms such as rough idle, excessive smoke, increased fuel consumption, decreased engine performance, and a check engine light. Therefore, it is important to ensure that the EGR temperature sensor is functioning properly. Additionally, the EGR position sensor detects the movement and position of the EGR valve pintle, while the EGR pressure sensor detects exhaust gas flow through the EGR passage.

In summary, the EGR temperature sensor is an integral component of the Cummins ISX engine. Its proper functioning is essential for optimal engine performance and efficiency.

: Demystifying The Function Of The Egr Temperature Sensor

Cummins ISX engines are equipped with an Exhaust Gas Recirculation (EGR) system, which helps reduce emissions and improve fuel efficiency. The EGR temperature sensor plays a crucial role in this system. Its function is to monitor the temperature of the exhaust gas being recirculated back into the engine.

The location of the EGR temperature sensor may vary depending on the engine model, but it is commonly found near the EGR valve or within the EGR cooler. It is important for the sensor to accurately measure the temperature to ensure proper engine performance and emission control.

Factors that can affect the performance and accuracy of the EGR temperature sensor include carbon buildup, sensor damage, and electrical connection issues. Regular maintenance and inspection of the sensor is recommended to ensure optimal operation of the EGR system.

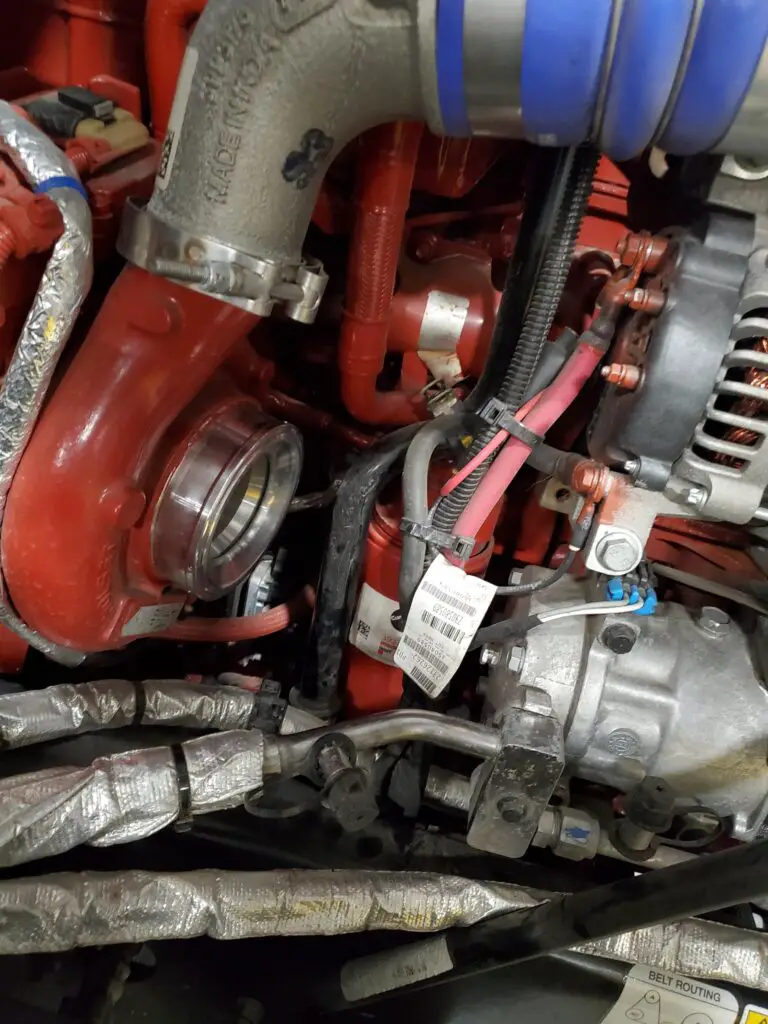

: Locating The Egr Temperature Sensor On A Cummins Isx Engine

Overview of the engine layout and key components:

The Cummins ISX engine is a popular choice for heavy-duty vehicles and is known for its power and reliability. Understanding the engine layout and key components can help in locating the EGR temperature sensor.

Some key components of the engine include the coolant temperature sensor, EGR valve, EGR position sensor, EGR pressure sensor, and the exhaust gas pressure sensor. These sensors and valves play a crucial role in the engine’s performance and emission control system.

Step-by-step guide on finding the EGR temperature sensor:

- Consult the engine’s service manual and locate the EGR temperature sensor on the engine diagram.

- Open the hood and locate the intake and exhaust manifolds.

- Follow the exhaust manifold to find the EGR valve. The EGR temperature sensor is usually located near the EGR valve.

- Inspect the wiring and connectors to identify the sensor.

- If needed, refer to online resources or videos for visual guidance on sensor location.

Common misconceptions and troubleshooting tips for locating the sensor:

One common misconception is that the EGR temperature sensor is located on the intake manifold. However, it is usually found near the EGR valve on the exhaust manifold. Some troubleshooting tips include checking for any visible wires and connectors related to the EGR system and referring to the engine’s service manual for accurate information on sensor location.

Credit: www.frontiersin.org

: Coolant Temperature Sensor

The coolant temperature sensor is an essential component of the Cummins ISX engine. It is located on top of the thermostat housing and can be found behind the outlet hose. This sensor plays a crucial role in monitoring the temperature of the coolant, which helps the engine control strategy. By understanding the function and location of the sensor, you can easily locate it on your engine.

When it comes to the function of the sensor, it is responsible for measuring the temperature of the coolant and sending the information to the engine control unit. This data is then used to adjust fuel injection timing, optimize engine performance, and prevent overheating or freezing of the coolant. The location of the sensor behind the outlet hose ensures that it accurately measures the temperature of the coolant as it exits the engine.

: Air Temp Sensor

The air temp sensor for the Cummins ISX EGR system is typically located on the side of the engine block, while other sensors such as the exhaust gas pressure sensor and EGR sensor can be found near the injector pump.

The engine oil pressure sensor is usually located close to the oil filter housing.

The air temp sensor on a Cummins ISX engine is usually located on the side of the engine block. It is an important sensor in engine performance, as it monitors the temperature of incoming air. In addition to the air temp sensor, there are other sensors commonly found in proximity to it. These include the exhaust gas pressure sensor and the EGR sensor, which are often located near the injector pump. The engine oil pressure sensor is typically found close to the oil filter housing. These sensors play a crucial role in monitoring and controlling various aspects of the engine’s performance. By providing important data to the engine control strategy, they help ensure optimal engine function. Understanding the location and function of these sensors can assist in troubleshooting and maintenance of the Cummins ISX engine.: Exhaust Gas Pressure Sensor And Egr Sensor

Cummins ISX engine is equipped with several important sensors, including the exhaust gas pressure sensor and EGR sensor. These sensors play crucial roles in the engine’s control strategy and performance optimization.

The exhaust gas pressure sensor measures the pressure of the exhaust gases, enabling the engine control unit (ECU) to monitor the combustion process and adjust fuel injection accordingly. On the other hand, the EGR sensor detects the movement and position of the EGR valve pintle, as well as the flow of exhaust gas through the EGR passage.

Typically, the exhaust gas pressure sensor and EGR sensor can be found near the injector pump, facilitating easy access for monitoring and maintenance purposes. Additionally, the engine oil pressure sensor is usually located in close proximity to the oil filter housing, ensuring efficient monitoring of engine oil pressure.

It is important to maintain the proper functioning of these sensors to ensure optimal engine performance, fuel efficiency, and emissions control.

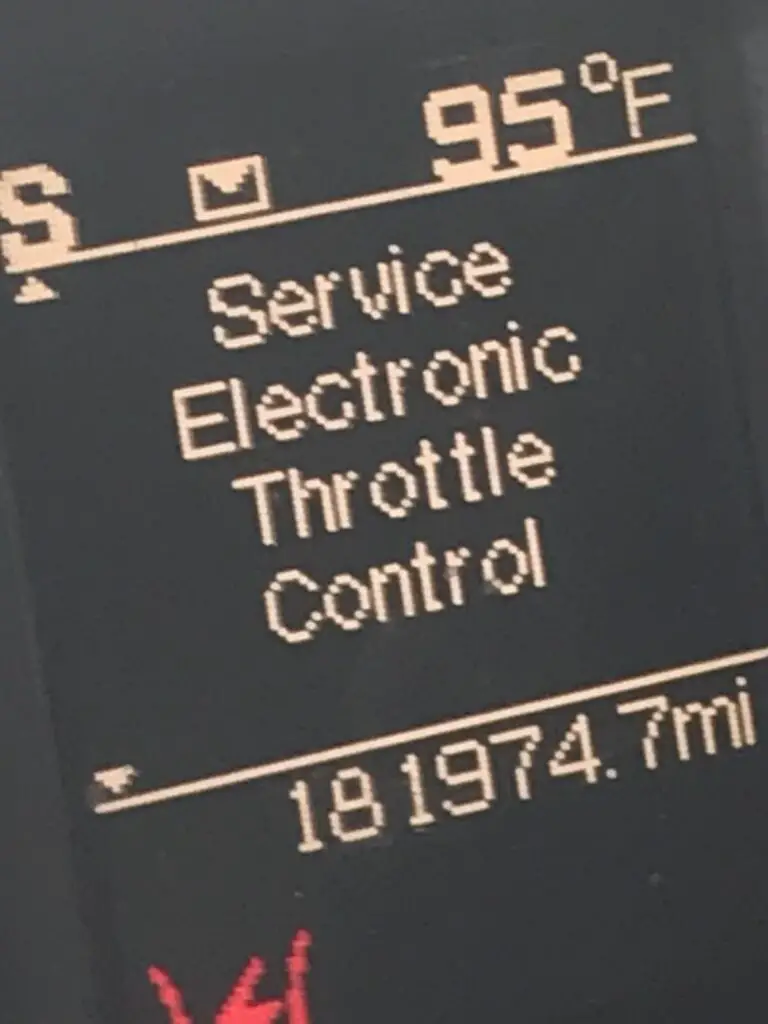

: Recognizing Symptoms Of A Faulty Egr Temperature Sensor

Recognizing symptoms of a faulty EGR temperature sensor is crucial for Cummins ISX engine owners. Ensure efficient engine performance by identifying signs such as rough idle, excessive smoke, increased fuel consumption, decreased engine performance, and a check engine light. Stay proactive in maintaining your engine’s health.

| Recognizing Symptoms of a Faulty EGR Temperature Sensor |

| Identifying potential issues associated with a bad EGR temperature sensor can help prevent further engine damage and costly repairs. Some common symptoms include: |

|

| A rough idle is often one of the first signs of a faulty EGR temperature sensor. The engine may run roughly or even stall at idle. Excessive smoke, especially black smoke, can indicate improper combustion caused by a malfunctioning sensor. Another common issue is increased fuel consumption, as the sensor may not regulate the amount of recirculated exhaust gases properly. This can result in reduced fuel efficiency and higher operating costs. Additionally, a faulty EGR temperature sensor can lead to decreased engine performance, including power loss and reduced acceleration. In some cases, the check engine light may also illuminate as a result of a malfunctioning sensor. Regular inspection and maintenance of the EGR temperature sensor can help identify and resolve these issues promptly. |

: Maintaining And Replacing The Egr Temperature Sensor

The EGR temperature sensor plays a crucial role in the overall performance of the Cummins ISX engine. Regular maintenance and inspection of this sensor is important to ensure optimal functionality and prevent potential issues.

If you notice any symptoms such as rough idle, excessive smoke, increased fuel consumption, decreased engine performance, or a check engine light, it may be indicative of a faulty EGR valve. In such cases, safely replacing the sensor is necessary.

Here is a step-by-step guide to replacing a faulty EGR temperature sensor:

- Start by locating the sensor. It is typically situated near the injector pump or the engine block.

- Disconnect the sensor’s electrical connector by carefully disengaging the plug.

- Remove any mounting bolts securing the sensor in place.

- Gently pull out the old sensor and replace it with a new one.

- Secure the new sensor by reinstalling the mounting bolts.

- Reconnect the electrical connector by carefully inserting the plug.

- Ensure proper installation and functionality by performing a thorough inspection.

Remember to follow the manufacturer’s guidelines and take necessary precautions during the replacement process to avoid any damage to the sensor or the engine.

By regularly maintaining and inspecting the EGR temperature sensor, you can ensure the efficient and reliable operation of the Cummins ISX engine.

Frequently Asked Questions Of Cummins Isx Egr Temperature Sensor Location

Where Is The Temperature Sensor On A Cummins Isx?

The temperature sensor on a Cummins ISX is located on top of the thermostat housing, behind the outlet hose. It is the coolant temperature sensor.

What Is Egr Temperature Sensor?

The EGR temperature sensor is used to monitor the temperature in a vehicle’s engine as part of the engine control strategy. It helps in detecting any issues with the Exhaust Gas Recirculation system.

What Are The Symptoms Of A Bad Egr Valve On An Isx Cummins?

Symptoms of a bad EGR valve on an ISX Cummins include rough idle, excessive smoke, increased fuel consumption, decreased engine performance, and a check engine light.

What Sensor Connects To The Egr?

The EGR position sensor and EGR pressure sensor connect to the EGR valve for monitoring its movement and exhaust gas flow. It helps with engine control and detecting any issues related to the EGR system.

Conclusion

To locate the Cummins ISX EGR temperature sensor, you can refer to the coolant temperature sensor located on top of the thermostat housing. This sensor plays a crucial role in monitoring the temperature of the engine and contributes to the engine control strategy.

If you notice symptoms like rough idle, excessive smoke, increased fuel consumption, or a decreased engine performance, it might indicate a faulty EGR valve. Replacing the EGR temperature sensor with a direct replacement will ensure the engine control unit functions optimally.