Service Electronic Throttle Control: A Complete Diagnostic and Reset Guide (Ford, RAM, GM)

Part 1: The “Service Electronic Throttle Control” Warning: What to Do

That illuminated warning light on the dashboard is one of the most alarming indicators a driver can face. When the “Service Electronic Throttle Control” (ETC) light activates, it represents a critical fault within the system that translates pedal movement into engine power. This light, often appearing as a red lightning bolt (common on Dodge, Ram, and Jeep vehicles) or a throttle body icon, signals a more immediate and severe issue than a standard check engine light.

It indicates that the Powertrain Control Module (PCM)—the vehicle’s central computer—has detected a significant discrepancy or failure in the Drive-by-Wire system and can no longer trust the data it is receiving.

“Limp Mode” (Failsafe Mode) Explained

The most common and frightening symptom that accompanies the ETC light is a sudden, drastic loss of engine power, known as “Limp Mode” or “Failsafe Mode”. It is critical to understand that this is not a component failure; it is a deliberate, programmed safety feature.

When the PCM determines it cannot reliably control the throttle (a condition that could lead to dangerous unintended acceleration ), it overrides driver inputs and restricts engine performance to prevent a potential accident. This allows the driver to “limp” the vehicle to a safe location but makes normal driving impossible.

The symptoms of Limp Mode are unmistakable:

- Drastic Power Reduction: The engine will feel sluggish, and the accelerator pedal may feel completely “dead” or unresponsive.

- Limited Engine RPM: The PCM will prevent the engine from revving above a low threshold, often 1,500 or 2,000 RPM.

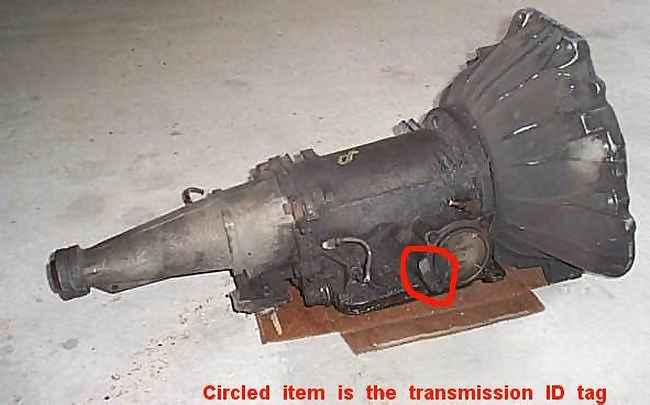

- Locked Transmission Gear: To prevent further complications, the PCM may lock the transmission into a single, safe gear, such as 3rd gear, preventing it from upshifting or downshifting.

The activation of the ETC warning light is the cause of limp mode. The PCM has lost its “trust” in the throttle system’s feedback loop and has chosen the safest possible action: removing power from the equation. This is fundamentally different from a standard Check Engine Light, which often signals an emissions-related fault. The ETC light signifies a direct, active problem with vehicle control and safety.

What to Do Immediately

Seeing this light and experiencing limp mode, especially at highway speeds, can be terrifying.

- Do Not Panic: Understand that the vehicle is in a self-preservation mode. The engine is not about to explode, but its control system is compromised.

- Pull Over Safely: Do not attempt to “push through” the problem. Find the nearest safe location—a shoulder, exit ramp, or parking lot—to get out of the flow of traffic. Driving a vehicle in limp mode is dangerous, as it cannot accelerate to match traffic speed.

- Perform an Ignition Cycle (Temporary Fix): In many cases, this fault can be temporarily cleared. Pull over, shut the engine off completely, remove the key (or power down the push-start system), and wait 30-60 seconds. Then, restart the engine. This forces the PCM to reboot and run a new self-diagnostic test. If the fault was intermittent, the light may go off, and full power may be restored.

- Do Not Trust a Temporary Fix: Even if the vehicle drives normally after a restart, the root cause of the fault is still present.10 The underlying issue (a bad sensor, a sticking throttle plate, or wiring fault) will happen again. The vehicle must be diagnosed and repaired properly.

The Complete Guide to Electronic Throttle Control (ETC)

Your truck’s Electronic Throttle Control (ETC) is crucial for engine performance. When it acts up, a reset might be the answer. This guide breaks down the symptoms, causes, and solutions.

…of Performance Issues Can Be Traced

A significant percentage of common driveability problems like rough idle, stalling, and poor acceleration are linked to a dirty or miscalibrated Electronic Throttle Body.

Symptoms of a Failing ETC

These are the most common warning signs that your truck’s ETC system needs attention. The “Check Engine” or “ETC” warning light is often the first indicator.

Common Causes of ETC Malfunction

Before attempting a reset, it’s vital to understand what causes the issue. Most often, it’s not a broken part, but a dirty one.

A Typical ETC Reset & Diagnostic Flow

A “reset” isn’t just one procedure; it’s a process of diagnosis and relearning. Follow these steps in order to properly service your ETC system.

Ensure the battery is fully charged and terminals are clean. A low-voltage situation is a common cause of ETC glitches.

This is the most likely culprit. Disconnect the intake and use a dedicated throttle body cleaner to remove all carbon buildup from the plate and bore.

Many trucks have a specific sequence of turning the key and pressing the accelerator (the “pedal dance”) to force the ECU to relearn the throttle’s idle and wide-open positions. Check your owner’s manual.

If the pedal relearn fails, disconnect the negative battery terminal for 15-30 minutes. This forces a hard reset of the ECU, which will then relearn throttle positions on its own during the next drive cycle.

If problems persist, the issue is deeper. A professional-grade scan tool can command the ETC reset directly and read error codes related to failed sensors or wiring.

DIY vs. Professional Service

Knowing your limits is key. While cleaning and basic resets are great DIY tasks, diagnosing a faulty sensor or wiring is best left to a professional.

| Task | DIY-Friendly | Requires Professional |

|---|---|---|

| Throttle Body Cleaning | ✔ | ✖ |

| Pedal Relearn Procedure | ✔ | ✖ |

| Battery Disconnect Reset | ✔ | ✖ |

| Reading Basic Error Codes | ✔ | ✖ |

| Diagnosing Sensor Failure | ✖ | ✔ |

| Checking Wiring Harness | ✖ | ✔ |

| Throttle Body Replacement | ✖ | ✔ |

Part 2: Understanding Your Truck’s “Drive-by-Wire” System

To diagnose and fix the “Service ETC” light, one must first understand the system that generates the warning. Modern vehicles no longer use a physical cable connecting the gas pedal to the engine. That mechanical system has been replaced by a sophisticated electronic system called Electronic Throttle Control (ETC), or “Drive-by-Wire”.

In the old mechanical system, pressing the pedal directly pulled a cable that opened a valve (the throttle plate) in the throttle body, letting in more air. The simplicity was its strength, but it was “dumb.” It could not be integrated with modern engine management or safety systems.

Drive-by-Wire, as the name implies, replaces that steel cable with sensors, wires, and an electric motor. This “X-by-Wire” technology is an integrated approach that allows computers and electronics to manage core vehicle functions, which is what enables features like cruise control, traction control, stability control, and improved fuel efficiency.

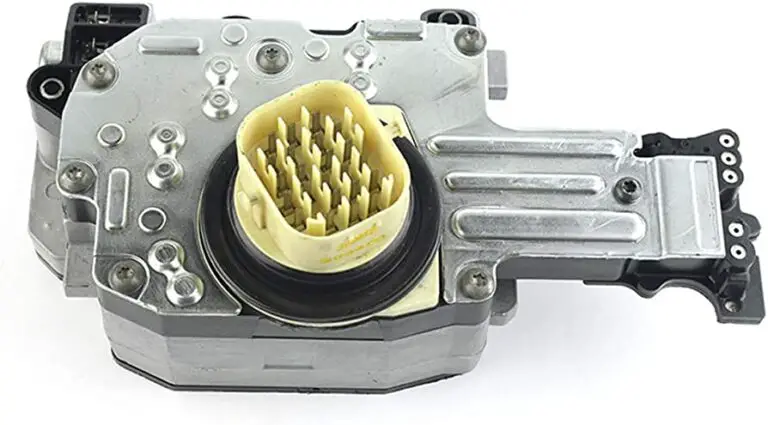

The 4 Key Components of the ETC System

The ETC system consists of four primary components working in a continuous, high-speed feedback loop.

- The Accelerator Pedal Position (APP) Sensor: The “gas pedal” is no longer just a pedal; it is a complex sensor module.17 When the driver presses it, redundant sensors (often two or three) inside the module translate the physical position into a variable voltage signal. This signal is the “request”—the driver is requesting a certain amount of torque.

- The Powertrain Control Module (PCM): This is the truck’s central brain. It receives the “request” signal from the APP sensor. However, it does not obey it blindly. The PCM’s software analyzes this request against dozens of other data points in real-time: current engine speed, vehicle speed, transmission gear, anti-lock brake status, and traction control or cruise control commands. Only after this analysis does the PCM decide on the actual throttle angle needed.

- The Electronic Throttle Body (ETB): This housing on the engine’s air intake contains two key parts: the throttle plate (a butterfly valve that opens to let air in) and a small, precise electric motor (the throttle actuator). The PCM sends a “command” signal to this motor, telling it to open the throttle plate to a specific angle (e.g., 15.4 degrees).

- The Throttle Position Sensor (TPS): This is the final, critical piece of the loop. Located directly on the throttle body, the TPS (which also has redundant sensors) measures the actual, physical position of the throttle plate. It sends this “feedback” signal back to the PCM.

This entire system operates on a “closed loop of trust.” The PCM is in constant communication, performing plausibility checks hundreds of times per second. It checks:

- “Does APP Sensor 1’s signal agree with APP Sensor 2’s?”

- “Does TPS Sensor 1’s signal agree with TPS Sensor 2’s?”

- And most importantly: “Did the feedback from the TPS match the command I sent to the ETB motor? And does this all ‘make sense’ compared to the request from the APP sensor?”.

The “Service ETC” light illuminates the very instant the answer to any of those questions is “No.” The system is no longer “trustworthy,” and the PCM’s only safe response is to shut it down and engage Limp Mode. This reframes the diagnostic process: the goal is to find the source of this data conflict.

How “Drive-by-Wire” (ETC) Works

(Diagram Description)

- Title: The ETC “Closed Loop of Trust”

- Box 1: Driver presses pedal -> **** (Sends “Request” Signal)

- Arrow to Box 2: -> [Powertrain Control Module (PCM)] (Analyzes request vs. other data: engine speed, traction control, etc.)

- Arrow to Box 3: -> **** (Executes “Command” Signal to open/close throttle plate)

- Arrow to Box 4: -> **** (Measures plate’s actual position and sends “Feedback” Signal)

- Looping Arrow: An arrow loops from Box 4 back to Box 2, labeled “VERIFICATION: PCM Verifies Feedback Matches Command.”

- Warning Box: If Feedback $\neq$ Command, PCM triggers “Service ETC” Light + Limp Mode.

Part 3: Diagnosing the Root Cause: Why Is the ETC Light On?

Attempting to perform a “reset” without first diagnosing the underlying problem is futile. The light will simply return. The fault must be identified and repaired. The following are the most common culprits, from most to least likely.

The #1 Culprit: A Dirty, Sticking Throttle Body

By far, the most common cause of an ETC fault, especially on trucks with over 80,000-100,000 miles, is not an electronic failure but a simple mechanical one: dirt.

The engine’s Positive Crankcase Ventilation (PCV) system is designed to vent unburnt fuel and oil vapors from the crankcase back into the air intake to be burned. Over time, these oily vapors, combined with fine dust, cook onto the inside of the throttle body and the edges of the throttle plate.

This black, sticky carbon buildup physically restricts the plate’s movement. The PCM’s actuator motor is designed for micro-fine adjustments. When it tries to open or close the plate by a fraction of a degree (especially at idle), the plate sticks in the grime, then suddenly pops free.

This physical binding is what triggers the fault. The PCM commands a small movement, but the TPS reports no movement (it’s stuck), then too much movement (it popped free). This data mismatch violates the “loop of trust.” This is the classic cause for Diagnostic Trouble Code (DTC) P2112: Throttle Actuator Control System – Stuck Closed.

In many cases, the fix is not an expensive part replacement, but a $10 can of throttle body cleaner. This is why a guide on is the essential first step in this repair.

Faulty Sensors: Accelerator Pedal (APP) vs. Throttle Position (TPS)

If the throttle body is clean, the next logical suspects are the sensors themselves. These sensors are often potentiometers, which work like a volume knob, and they can develop “dead spots” or wear out over time. It is crucial to differentiate which sensor is failing.

- Bad Accelerator Pedal Position (APP) Sensor: The fault is at the driver’s foot. The PCM is not receiving a clean “request” signal.

- Symptoms: This is the most common cause of a “dead pedal,” where pressing the accelerator does nothing. It can also cause an erratic engine response, where the truck seems to speed up or slow down on its own, as if it’s reading a phantom pedal input. It may also lead to a high idle.

- Bad Throttle Position Sensor (TPS): The fault is at the engine. The PCM is not receiving a clean “feedback” signal. (Note: On most modern trucks, the TPS is integrated into the throttle body assembly and cannot be replaced separately).

- Symptoms: This is more likely to cause poor, sluggish acceleration, hesitation when the pedal is pressed, a very rough or unstable idle, and engine stalling.

A simple way to think about it: A failing APP sensor means the PCM doesn’t know what the driver wants. A failing TPS means the PCM doesn’t know what the engine is doing. Both will trigger an ETC light and limp mode, but a “dead pedal” strongly points to the APP sensor.

Other Potential Causes

If the throttle body is clean and the sensors seem okay, the investigation must broaden.

- Vacuum Leaks: This is a common, and often misdiagnosed, issue. A cracked vacuum hose, a failed intake manifold gasket, or a bad PCV valve allows “unmetered air” to be sucked into the engine after the throttle body. The PCM sees a normal, stable reading from the TPS (e.g., 2% open at idle), but the oxygen sensors downstream are reporting a “lean” condition (too much air), and the engine idle is surging. This creates a data conflict that can, in some vehicles, trigger an ETC fault. More commonly, it causes a persistent rough idle in your truck and lean codes (P0171, P0174).

- Electrical Issues: Never underestimate the simple fixes. These sensors operate on a very precise 5-volt reference signal. A loose electrical connector at the throttle body or APP sensor, wiring that has chafed against the engine block, or a corroded main engine ground can interrupt or degrade this signal, causing an instant fault.

- PCM/Software Glitches: In some cases, particularly on certain Jeep and Ram models, the hardware is fine, but the PCM’s software logic is flawed. The computer may be too sensitive and trigger a false “Service ETC” light. In these instances, a dealership may need to apply a Technical Service Bulletin (TSB) to update or “re-flash” the PCM’s software.

Part 4: Data-Driven Diagnostics: Symptoms and Trouble Codes (DTCs)

A “Service ETC” light is almost always accompanied by one or more Diagnostic Trouble Codes (DTCs) stored in the PCM. Using an OBD-II scanner to read these codes is the first step in any professional diagnosis. The symptom the driver feels can be correlated with the code the PCM stores.

Symptom-to-Cause Diagnostic Table

The following table synthesizes common driver complaints with their most probable mechanical or electrical causes.

| Symptom | Most Likely Cause (In Order of Probability) | Supporting Data |

| “Service ETC” Light + Limp Mode | 1. Failed APP Sensor 2. Failed Throttle Body (TPS or Actuator) 3. Severe data mismatch (APP vs. TPS) | [7, 9, 20, 34] |

| High, Rough, or “Surging” Idle | 1. Dirty/Sticking Throttle Body (PCM can’t control idle) 2. Vacuum Leak (unmetered air) 3. Needs Throttle Relearn (after recent service) | [23, 31, 35, 36] |

| Hesitation / Sluggish Acceleration | 1. Dirty Throttle Body 2. Failing Throttle Position Sensor (TPS) (bad spot on resistor) 3. Failing Mass Air Flow (MAF) Sensor | [7, 26, 27, 35] |

| “Dead Pedal” / No Throttle Response | 1. Failed Accelerator Pedal Position (APP) Sensor 2. Blown ETC fuse or wiring issue 3. Failed Throttle Actuator Motor | [5, 10, 20] |

| Sudden, Unintended Acceleration | 1. Failed APP Sensor (sending false “full throttle” signal) 2. Throttle Plate Stuck Open (mechanical) 3. Critical safety issue – stop driving immediately. | 8 |

| Poor Fuel Economy | 1. Dirty/Failing Throttle Body (incorrect air/fuel mix) 2. Vacuum Leak | [7, 23, 31, 35] |

Understanding Your OBD-II Trouble Codes (DTCs)

While dozens of codes relate to the ETC, two are overwhelmingly common.

DTC P0121: Throttle/Pedal Position Sensor “A” Circuit Range/Performance

- What it means: This is the quintessential “data conflict” code. It does not mean the sensor is dead. It means the signal the PCM is receiving from the TPS is illogical or “out of the expected range”. The PCM’s software has a map of expected values. For example, at idle, it expects to see a TPS signal of ~0.5 volts. If it sees 0.2V, or if it sees 1.5V but the Manifold Absolute Pressure (MAP) sensor signal doesn’t agree, the PCM flags the TPS signal as “implausible”.

- Common Fixes:

- Clean the throttle body. A plate that is sticking or caked in carbon can cause the sensor to send an illogical signal that doesn’t match engine RPM.

- Check the wiring. Inspect the TPS connector and wiring harness for moisture, corrosion, or damage.

- Replace the throttle body assembly. Since the TPS is usually integrated, a faulty sensor requires replacing the entire unit.

DTC P2112: Throttle Actuator Control (TAC) System – Stuck Closed

- What it means: This code is a direct report of a mechanical failure. The PCM commanded the throttle actuator motor to open the plate, but the TPS is reporting that the plate is still closed (or has not opened to the commanded angle). The PCM has detected that its command was not obeyed.

- Common Fixes:

- CLEAN THE THROTTLE BODY. This is the solution in the vast majority of cases. The plate is not stuck because the motor is weak; it is physically bonded to the throttle bore by carbon buildup.

- Check for a faulty throttle actuator motor (i.e., the throttle body itself has failed internally).

- Replace the throttle body assembly.

Part 5: The “Throttle Relearn”: Why a Reset is Critical After Service

This brings us to the core of the issue: the “reset.” After cleaning or replacing the throttle body, a final step is required. This procedure is known as a “throttle relearn,” “throttle body relearn,” “throttle calibration,” or “resetting adaptive values”.

What is a “Throttle Relearn”?

A throttle relearn is a procedure that clears the PCM’s stored “adaptive memory” specific to the throttle body. It forces the PCM to recalibrate itself and find the new baseline “fully closed” and “fully open” electronic positions of the throttle plate.

The “Adaptive Memory” Problem (Why a Relearn is Necessary)

This is the most critical concept for any DIY mechanic to understand, as it explains the most common post-repair problem: a new, persistent high idle.

A high idle after cleaning a throttle body is not a sign of failure. It is a sign of success. It is tangible proof that the cleaning was effective, and it indicates that a relearn is now mandatory.

Here is the step-by-step logic:

- Adaptation: Over 100,000 miles, as carbon and gunk slowly build up, the throttle plate’s “fully closed” position becomes restricted. Airflow is reduced.

- Compensation: The PCM, which is programmed to maintain a smooth 600 RPM idle, adapts to this buildup. To get the required air past the gunk, it learns that it must hold the “dirty” throttle plate open just a little bit—for example, 5% open—to achieve a 600 RPM idle.

- Memory: This 5% opening becomes the PCM’s new, learned “zero” or “base idle” position. This value is stored in its Keep Alive Memory (KAM).

- The Repair: A mechanic (or DIY-er) then services the truck, removing the throttle body and cleaning it until it is spotless. All the carbon buildup is gone.

- The “Symptom of Success”: The mechanic reinstalls the clean throttle body and starts the engine. The PCM, still using its old adaptive memory, immediately commands the now-spotless plate to open to its learned “zero” of 5%.

- The Result: A 5% opening on a clean plate allows a massive influx of air, far more than the engine needs. The idle immediately races to 1,500, 2,000, or even 2,500 RPM. The mechanic panics, thinking they broke something.

They broke nothing. They simply proved that the cleaning worked and must now complete the job. The “throttle relearn” is the process of forcing the PCM to erase that “5% open” memory and re-discover that the new, correct “zero” position for the clean plate is (for example) 0.5% open.

Failure to perform this relearn after a cleaning or replacement will result in a persistent high idle, rough idle, hesitation, stalling, and poor fuel efficiency, as the PCM’s stored values no longer match the physical reality of the engine.

Part 6: How to Reset Your Electronic Throttle Control: 3 Methods

There are three primary methods to perform this relearn. They range from a crude “sledgehammer” approach to a precise “scalpel” method.

Method 1 (The “Sledgehammer”): The Battery Disconnect Reset

This is a “hard reset” of the PCM, also known as a capacitive discharge. It forces the PCM to dump all of its learned adaptive values.

- How to Do It:

- Disconnect the negative battery terminal.

- Wait at least 15-30 minutes. This allows the capacitors inside the PCM to fully discharge, erasing the Keep Alive Memory (KAM).

- (Optional Mechanic’s Trick): To accelerate this process, disconnect both the positive and negative battery cables. Touch the metal cable ends together for 60 seconds. This drains the residual power instantly. Warning: Never touch the battery terminals themselves together.

- Reconnect the battery terminals (positive first, then negative).

- The PCM’s memory is now cleared. A vehicle-specific relearn procedure (see Part 7) may still be required.

- Pros: It is 100% free and effectively clears the faulty adaptive memory.

- Cons: This is a “dumb” or “brute-force” reset. It erases everything—not just the throttle adaptations. This includes radio presets, the clock, powertrain fuel trims, and, most importantly, the transmission’s adaptive shift-point memory. The truck may run and shift erratically for the first 30-50 miles of driving as it relearns all of these parameters from scratch.

Method 2 (The “Guided Suggestion”): Manual Relearn Procedures

These procedures use a specific, manufacturer-defined sequence of ignition cycles and pedal movements to trigger the PCM’s built-in throttle relearn logic without erasing all KAM.

- General Procedure (Varies by OEM – see Part 7 for specifics):

- Turn the ignition key to the ON position (do not start the engine).

- Listen for the soft buzzing/clicking from the throttle body to stop (this can take 3-10 seconds).

- Alternatively, some models require a slow press of the accelerator pedal all the way to the floor, followed by a slow release.

- Turn the ignition key to the OFF position for at least 10 seconds.

- Start the engine and let it idle, undisturbed (do not touch the pedal or A/C), for 10-15 minutes as it recalibrates.

- Pros: It is free and does not erase other learned values like radio presets.

- Cons: This method is notoriously finicky and vehicle-specific. It is not a guaranteed fix. Often, a manual reset helps the idle, but a full scan tool relearn is what truly solves it.

Method 3 (The “Scalpel”): Professional OBD-II Scan Tool Relearn

This is the OEM-intended, most reliable, and professional method for resetting the throttle body.

- How to Do It:

- Connect a bi-directional scan tool (not a simple code reader) to the vehicle’s OBD-II port. Brands like XTOOL, ANCEL, Autel, or Foxwell offer this function.

- Turn the ignition to ON (engine off).

- On the scan tool, navigate from the main menu to “Service Functions,” “Maintenance,” or “Special Functions”.

- Select the specific function labeled “Throttle Relearn,” “Throttle Body Adjustment (TBA),” “Throttle Actuator Control (TAC) Relearn,” or “Reset Adaptive Values”.

- Follow the on-screen prompts precisely. The tool will send a direct command to the PCM, forcing it to instantly clear the old values and begin the new relearn sequence.

- Pros: It is 100% reliable, extremely fast (often taking 5-10 minutes), and is the correct, professional-grade procedure.

- Cons: This method requires a bi-directional scan tool, which can cost $150 or more. Alternatively, a repair shop will perform this service, typically for a fee of $50 to $150.

Comparison of Throttle Reset Methods

| Method | Reliability | Cost | Time Required | Potential Side Effects |

| 1. Manual Relearn (Key-on/Pedal) | Medium. Highly vehicle-specific; may not work on all models or may only be partially effective. | Free | 15-20 minutes | Low. The most common side effect is that it simply fails to work. |

| 2. Battery Disconnect (Hard Reset) | High. This reliably forces a reset of all adaptive memory, including the throttle values. | Free | 20-30 minutes | High. Erases all KAM, including radio presets, fuel trims, and transmission shift points, which can lead to erratic driving for a short period.48 |

| 3. OBD-II Scan Tool (Service Function) | Excellent. This is the OEM-intended, direct-command method that is 100% effective. | $50-$150 (Shop Fee) or $150+ (Tool Cost) | 5-10 minutes | None. This is the correct, precise, and professional procedure. |

Part 7: Truck-Specific Throttle Relearn Procedures (Ford, RAM, GM)

The manual relearn procedures are not universal. The steps for a Ford are completely different from those for a RAM or GM. Using the wrong procedure will not work.

Guide 1: Ford F-150 / 6.2L Gas Engine Idle Relearn Procedure

This procedure is typically performed after the Keep Alive Memory (KAM) has been cleared, either by using a scan tool or the battery disconnect method.

- Step 1: Start the engine and run it until it reaches normal operating temperature (the temperature gauge is in the middle).

- Step 2: Bring the vehicle to a complete stop and place the transmission in Park (P).

- Step 3: Turn all accessories OFF (A/C, radio, headlights).

- Step 4: Allow the engine to idle undisturbed for at least one minute.

- Step 5: Turn the air conditioning (A/C) ON (set to Max A/C).

- Step 6: Allow the engine to idle undisturbed for at least one minute.

- Step 7: With the A/C still ON, press and hold the brake pedal. Shift the transmission into Drive (D).

- Step 8: Allow the engine to idle undisturbed for at least one minute.

- Step 9: The idle should now be stabilizing. Drive the vehicle for at least 10-15 miles (Ford documentation suggests up to 30 miles 49) to allow the PCM to fully relearn its adaptive strategy.

- Note on Powerstroke Diesels: On diesel engines like the 6.0L or 7.3L Powerstroke, the throttle plate serves a different purpose, often related to EGR flow control or to create a vacuum for other systems. Throttle response issues on these trucks are more commonly related to the Accelerator Pedal Position (APP) sensor, the Idle Validation Switch (IVS), or sensor wiring, not a “relearn” procedure.

Guide 2: Dodge RAM (Hemi & Cummins) Throttle Relearn Procedure

This procedure is widely cited for most 2007-and-newer Chrysler, Dodge, and Jeep vehicles and is designed to be done before starting the engine.

- Step 1: Get into the driver’s seat and close the door. Do not touch the brake or accelerator pedals.

- Step 2: Turn the ignition key to the ON position (the position where the dashboard lights come on, but the engine does not crank). Do not start the engine.

- Step 3: Wait 10 seconds. This allows the throttle body to cycle and perform its own initialization. Listen for a faint click or buzz from the engine bay.

- Step 4: Slowly press the accelerator pedal all the way to the floor (until it clicks, if equipped).

- Step 5: Slowly release the accelerator pedal all the way up until it is at its resting position.

- Step 6: Turn the ignition key to the OFF position.

- Step 7: Wait at least 10 seconds.

- Step 8: The procedure is complete. Start the engine. The PCM has now relearned the pedal’s 0% and 100% request points and the throttle’s new range.

- Note on older models: Some older RAM trucks (e.g., a 2006 model) may require a fast 2-second press and release of the gas pedal, confirmed by a “ding” sound, but the “slow press” method is standard for most modern RAMs.

Guide 3: GM / Chevy Silverado / Sierra Idle Relearn Procedure

The official GM procedure, as noted in multiple Technical Service Bulletins, requires a scan tool (like the GM Tech 2®) to perform the “Throttle Learn Reset Procedure”. However, this manual process often works for gas engines after a battery disconnect or throttle body service.

- Step 1: Start the engine and place the transmission in Park (P).

- Step 2: Allow the engine to idle undisturbed (no pedal, no A/C) for 3 minutes.

- Step 3: Turn the engine OFF and wait for at least 1 minute (60 seconds).

- Step 4: Start the engine again and place the transmission in Park (P).

- Step 5: Allow the engine to idle undisturbed for another 3 minutes.

- Step 6: The idle should now be normal. If the idle is still high or unstable, the PCM may require a “Drive Cycle” to finish the relearn.

- Drive Cycle Procedure (if needed):

- Drive the truck until it reaches normal operating temperature.

- Drive the truck at a steady 45-55 MPH for 2-5 minutes.

- Perform several “decelerations,” meaning you coast (foot off the pedal) from 45 MPH down to 20 MPH.

- Allow the truck to have “extended idles,” such as sitting at a long stoplight for 1-2 minutes.

- After this drive cycle, park the truck and let it idle in Park for at least 5 minutes. The idle should now be fully relearned.

Part 8: Cost and Professional Repair Analysis

The cost to fix a “Service Electronic Throttle Control” light varies dramatically based on the root cause. A simple DIY cleaning may be all that is needed, while a failed component can be moderately expensive.

Estimated Throttle Control Repair Costs

| Repair Job | DIY Cost (Parts) | Professional Cost (Est. Parts + Labor) | Notes |

| DIY Throttle Body Cleaning | $5 – $15 (Can of cleaner) | N/A | Always try this first. A simple cleaning resolves many ETC faults. |

| Professional Cleaning / Relearn | N/A | $100 – $200 | This service involves a technician cleaning the throttle body and, critically, using a professional scan tool to perform the relearn.[8, 55] |

| APP Sensor Replacement (DIY) | $50 – $250 (Typical part cost) | $150 – $400+ | The cost of the accelerator pedal position sensor itself can vary wildly by model, from $10 to over $800. |

| Throttle Body Replacement | $150 – $500 (Aftermarket Part) | $450 – $900+ | This is the most expensive common repair. The average cost for a replacement is between $619 and $767.[67] This varies by truck; a Chevy Silverado 1500 averages $404-$576, while a Ford F-150 averages $449-$538.[67] |

Part 9: Authoritative FAQ: Electronic Throttle Control Reset

Q: What happens if I don’t reset my electronic throttle control after cleaning it?

A: It is highly likely that the vehicle will have a very high, erratic, or surging idle. It may also hesitate or stall when coming to a stop. The PCM’s “adaptive memory,” which learned to compensate for the dirty throttle body, is now sending incorrect commands to the clean one, resulting in a severe air/fuel mixture imbalance, poor performance, and bad fuel economy.

Q: Can cleaning the throttle body fix the “Service ETC” light?

A: Yes, absolutely. If the ETC light and limp mode are being caused by a throttle plate that is physically sticking due to carbon buildup, a thorough cleaning will remove the obstruction and fix the root cause. This is the most common fix for codes like P2112 (“Stuck Closed”). A relearn procedure must be performed immediately afterward.

Q: How do I know if it’s the throttle body (TPS) or the pedal (APP) sensor?

A: The most accurate way is to use an OBD-II scanner. The codes will point to the specific circuit (e.g., APP-specific codes often include P0220-P0229). Symptomatically, while both can cause limp mode, a completely “dead pedal” (where the engine idles fine but pressing the accelerator does nothing) is a very strong indicator of a bad APP sensor. Rough idle, stalling at stops, and hesitation are more commonly linked to the throttle body/TPS.

Q: Will just disconnecting the battery reset the throttle body?

A: Yes, performing a “hard reset” by disconnecting the battery for 15-30 minutes will clear the PCM’s Keep Alive Memory (KAM), which includes the faulty throttle adaptations. However, this is a “sledgehammer” approach. It also erases all other adaptations, including fuel trims and transmission shift points, which can cause the truck to run and shift poorly for the next 30-50 miles. It is not the preferred professional method but is effective.

Q: Can a vacuum leak cause an ETC warning?

A: A vacuum leak typically causes symptoms (like a high, surging idle) that are easily confused with an ETC fault. However, it will usually trigger different trouble codes, specifically “System Too Lean” (P0171 or P0174). This is because the PCM is getting conflicting data between its sensors (the TPS shows the throttle is closed, but the oxygen sensors show a high level of air), but it doesn’t blame the throttle itself.