5.7 Hemi Water Pump Bolt Torque Specs

The 5.7 Hemi water pump bolt torque specs are essential for ensuring the efficient and reliable operation of your engine’s cooling system. Proper torque application helps maintain a secure connection between the water pump and the engine, preventing leaks and ensuring optimal performance.

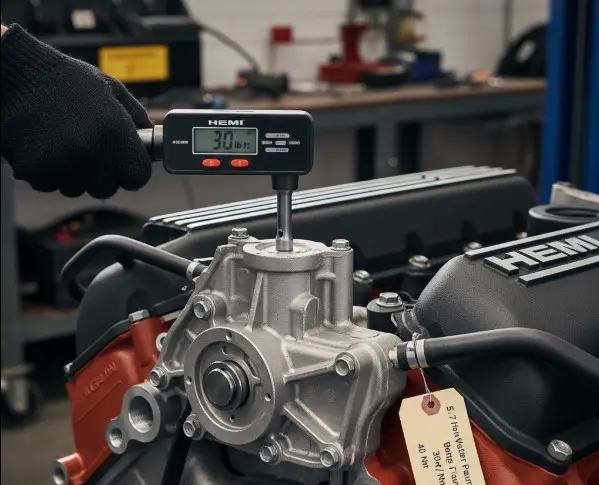

The recommended torque specification for the 5.7 Hemi water pump bolts is 18 ft-lbs (24 Nm). To achieve accurate torque, use a calibrated torque wrench and follow a step-by-step guide to ensure even tightening and a secure fit.

Related Article: 5.7 Hemi Engine Torque Specs

Remember, always consult your vehicle’s service manual for the most accurate torque specs and installation procedures.

| Engine Model | Water Pump Bolt Torque Specification |

|---|---|

| 2003-2008 5.7L Hemi | 30 Nm (22 ft-lbs) |

| 2009-2018 5.7L Hemi | 18 Nm (13 ft-lbs) |

| 2019-Present 5.7L Hemi | 18 Nm (13 ft-lbs) |

It is important to note that these specifications are subject to change, and it is always best to consult the manufacturer’s documentation or a reliable repair manual for the most up-to-date information. Additionally, it is important to follow the recommended torque sequence and to use a calibrated torque wrench to ensure proper torque values are achieved.

Water pump torque sequence

Understanding Torque Specs

Role of torque in fastening bolts

Torque is the force applied to a fastener, such as a bolt or a nut, to create a rotational or twisting action. It is typically measured in foot-pounds (ft-lbs) or Newton meters (Nm). When installing engine components, applying the correct torque is essential for ensuring that the parts are securely fastened, reducing the risk of leaks, vibrations, or damage due to stress.

By following the manufacturer’s recommended torque specifications, you can achieve a secure and reliable connection between the components.

Factors affecting torque requirements

Several factors can influence the torque requirements for fasteners in an engine, including:

- Material properties: The type of metal used for the fasteners and the engine components can affect the torque needed to secure them. Softer metals may require less torque, while harder metals may demand more torque to create a secure connection.

- Fastener size and thread pitch: The diameter and thread pitch of a bolt or nut can also impact the required torque. Larger fasteners typically need more torque to achieve the same clamping force as smaller fasteners.

- Lubrication: The presence of lubricants on the threads can reduce friction, allowing for more accurate torque application. Always follow the manufacturer’s recommendations on whether to use lubricants and which type to use.

Tools and techniques for accurate torque measurements

Using a calibrated torque wrench is the best way to ensure accurate torque application. These wrenches are designed to measure the applied torque and provide an audible or tactile signal when the desired torque is reached. It is essential to calibrate your torque wrench regularly to maintain accuracy.

When applying torque, follow these best practices:

- Start by hand-tightening the fastener to ensure proper thread engagement.

- Use the torque wrench to tighten the fastener to the manufacturer’s recommended torque specification.

- Apply torque evenly and gradually, avoiding sudden or jerky movements that could lead to over- or under-tightening.

- In cases where multiple fasteners are used, follow a specific tightening sequence (often specified by the manufacturer) to ensure even clamping force and prevent distortion or warping of components.

5.7 Hemi Water Pump Bolt Torque Specifications

Official torque specs for 5.7 Hemi water pump bolts

When installing or maintaining the water pump on a 5.7 Hemi engine, it is essential to follow the manufacturer’s recommended torque specifications. The official torque spec for the 5.7 Hemi water pump bolts is 18 ft-lbs (24 Nm).

Adhering to this torque value helps ensure a secure connection between the water pump and the engine, preventing leaks and ensuring optimal performance of the cooling system.

A step-by-step guide to proper torque application

To apply the correct torque to the 5.7 Hemi water pump bolts, follow these steps:

- Clean the threads of the bolts and the engine block to remove any dirt, debris, or old gasket material.

- Install a new water pump gasket, ensuring it is properly aligned with the bolt holes and coolant passages.

- Position the water pump on the engine block, aligning the bolt holes.

- Hand-tighten the water pump bolts to ensure proper thread engagement and alignment.

- Using a calibrated torque wrench, tighten the water pump bolts to the recommended torque of 18 ft-lbs (24 Nm). Follow the manufacturer’s specified tightening sequence if provided, to ensure even clamping force and prevent distortion of the pump or engine block.

- Reconnect any hoses, clamps, and other components that were removed during the water pump replacement process.

- Refill the cooling system with the appropriate coolant, following the vehicle manufacturer’s guidelines.

- Start the engine and check for any leaks or abnormal noises. If necessary, adjust the torque or address any other issues that may arise.

Tips for ensuring even and accurate bolt tightening

When tightening the 5.7 Hemi water pump bolts, keep these tips in mind to ensure even and accurate torque application:

- Use a calibrated torque wrench and follow the manufacturer’s recommendations for torque values and tightening sequences.

- Apply torque in a gradual and controlled manner, avoiding sudden or jerky movements.

- When tightening multiple bolts, alternate between them to distribute the clamping force evenly across the component.

- Regularly inspect the water pump and related components for signs of wear, damage, or leaks, addressing any issues promptly to maintain the engine’s cooling system efficiency.

Common Mistakes and Troubleshooting

Issues arising from incorrect bolt torque

Failing to apply the correct torque to the 5.7 Hemi water pump bolts can lead to a variety of issues, including:

- Leaks: Insufficient torque may result in loose connections, allowing coolant to leak from the water pump or engine block. Conversely, over-tightening can cause the gasket to compress too much, creating gaps for coolant to escape.

- Vibrations and noise: Improper torque can cause the water pump to sit unevenly on the engine block or vibrate during operation, leading to excessive noise or wear.

- Component damage: Over-tightening the bolts may cause the water pump housing or engine block to crack or warp, necessitating costly repairs.

Symptoms of improperly torqued water pump bolts

If the water pump bolts on your 5.7 Hemi engine are not torqued correctly, you may notice the following symptoms:

- Coolant leaks: Puddles of coolant under the vehicle or visible leaks from the water pump area may indicate improper torque.

- Overheating: A malfunctioning water pump can cause the engine to overheat, which may be evidenced by the temperature gauge reading higher than normal or warning lights on the dashboard.

- Unusual noises: Whining, grinding, or rattling noises from the water pump area may suggest that the bolts are not torqued correctly, causing the pump to vibrate or operate inefficiently.

Solutions and preventive measures

If you suspect that the water pump bolts on your 5.7 Hemi engine are improperly torqued, take the following steps to address the issue:

- Consult your vehicle’s service manual for the correct torque specifications and tightening sequences.

- Inspect the water pump, gasket, and engine block for any visible signs of damage or wear. Replace any damaged components as needed.

- Retorque the water pump bolts to the manufacturer’s recommended specifications using a calibrated torque wrench, following the proper tightening sequence.

- Perform regular maintenance on your vehicle’s cooling system, including checking the coolant level, inspecting hoses and clamps for wear, and replacing the water pump as needed.

By following these guidelines, you can ensure the proper torque is applied to the 5.7 Hemi water pump bolts and maintain the efficiency and reliability of your engine’s cooling system.

Credit: www.shophemi.com

FAQs

What is the correct torque specification for the 5.7 Hemi water pump bolts?

Why is it important to follow the correct torque specs when installing a water pump?

How can I ensure that I’m applying the correct torque to the water pump bolts?

What are the symptoms of improperly torqued water pump bolts?

How often should I inspect my vehicle’s cooling system and water pump?

How to Replace Water Pump Dodge Ram

Conclusion

Importance of adhering to torque specs for long-lasting performance

Following the correct torque specifications for the 5.7 Hemi water pump bolts is essential for maintaining the efficiency and reliability of your engine’s cooling system. Proper torque application ensures a secure and even connection between the water pump and engine block, preventing leaks, vibrations, and potential damage to components.

By adhering to the manufacturer’s recommended torque specs, you can contribute to the long-lasting performance of your engine and avoid costly repairs down the line.

Encouragement to consult professional resources for additional guidance

While this guide provides a comprehensive overview of the importance of torque specs and the proper installation of the 5.7 Hemi water pump, it is essential to consult your vehicle’s service manual for the most accurate and up-to-date information.

Professional mechanics and technicians can also provide valuable advice and assistance, ensuring that your engine’s cooling system operates at peak efficiency. By investing time and effort into understanding and applying the correct torque specifications, you can maintain the performance and longevity of your 5.7 Hemi engine.

Read Also: