6.4 Hemi Drive Belt Diagram

The 6.4 Hemi engine is a V8 engine that was produced by Chrysler from 2009 to present. The 6.4 Hemi has a cast-iron block and cylinder heads with hemispherical combustion chambers. It also has aluminum alloy connecting rods, forged steel crankshaft, and hydraulic roller tappets.

The 6.4 Hemi engine produces 485 horsepower at 6000 rpm and 475 lb-ft of torque at 4200 rpm.

If you’re looking for a 6.4 Hemi drive belt diagram, look no further! This handy guide will walk you through the process of finding and replacing the drive belt on your 6.4 Hemi engine.

First, locate the tensioner pulley.

This is typically located at the front of the engine, near the water pump. Once you’ve found it, use a wrench to loosen the tensioner nut and rotate the pulley clockwise. This will release the tension on the drive belt.

Next, slip the old drive belt off of all of the pulleys except for the idler pulley. The idler pulley is located at the bottom of the engine and does not have a tensioner attached to it. Once all of the other pulleys are free from the old drive belt, remove it completely from under the vehicle.

Now it’s time to install the new drive belt! Start by routing it around all ofthe same pulleys as before, except forthe idler pulley (again, this is located at thd bottomof thd engine). As you route thd new drivd blt around each pully, makd surd thatit’s positioned in thd sameway as thdonbd was (this can usually bdonbd by lookingat how thdonbd was routed and matchingit up).

Ram 6.4L Hemi Serpentine Belt Replacement – Diagram & Tips

6.4 Hemi Serpentine Belt

If you have a 6.4 Hemi engine, then you know that there is a special serpentine belt that is required to keep everything running smoothly. This belt is different than the standard belts found on other engines and it’s important to know how to properly care for it. Here are some tips on how to keep your 6.4 Hemi serpentine belt in good condition:

– Inspect the belt regularly for signs of wear or damage. If you see any cracks, fraying, or other damage, it’s time to replace the belt.

– Keep the belt clean and free of debris.

A build-up of dirt and grime can cause premature wear on thebelt.

– Make sure the tensioner and pulleys are in good working order. A worn tensioner can cause the beltto loosen over time and eventually fail.

2016 6.4 Hemi Belt Diagram

If you’re looking for a 2016 6.4 Hemi belt diagram, you’ve come to the right place. This detailed guide will show you exactly where to find the belt diagram for your truck’s engine.

First, let’s take a look at what the belt diagram looks like.

This particular one is for an 8-cylinder engine, but yours may be different depending on the make and model of your truck:

As you can see, the belt routes around several pulleys in the engine compartment. The main drive pulley is located at the front of the engine, while the other pulleys are located throughout the engine bay.

To find the specific location of each pulley on your truck’s 6.4 Hemi engine, consult your owner’s manual or service manual. These manuals will have a complete list of all the belts and pulleys in your engine, as well as detailed instructions on how to route them correctly.

Once you know where all of the pulleys are located, it’s time to start routing the belt.

Begin by threading it around the main drive pulley at the front ofthe engine. From there, followthe path shown in the diagram until you reachthe last pulley at the rearof the engine compartment.

It’s important to make sure that the belt is routed correctly; otherwise, it could slip off or become damaged over time.

2018 Ram 2500 6.4 Hemi Belt Diagram

If you’re in need of a 2018 Ram 2500 6.4 Hemi belt diagram, we’ve got you covered. Locate the desired position of the engine on the six-cylinder block. On the front of the engine, locate the crankshaft pulley.

The crankshaft pulley is located at the bottom of the engine in front of the oil filter housing. There are two bolts that hold this pulley in place; remove these bolts using a socket wrench and ratchet combination.

Once these bolts have been removed, pull off the old crankshaft pulley and discard it.

Line up the new crankshaft pulley with the bolt holes and install it onto the engine block using your socket wrench and ratchet combination.

2017 Dodge Ram 2500 Serpentine Belt Diagram

If you’re looking for a 2017 Dodge Ram 2500 Serpentine Belt Diagram, we’ve got you covered. This detailed diagram shows the path of the serpentine belt on the 2017 Dodge Ram 2500. We’ve also included a helpful guide to help you identify and replace the belt if needed.

Credit: www.billionautogroup.com

What is the 6

5 Creedmoor?

The 6.5 Creedmoor is a centerfire rifle cartridge designed specifically for target shooting. It was introduced in 2007 by Hornady and Ruger.

The 6.5 Creedmoor has become one of the most popular cartridges for long-range shooting, thanks to its accuracy and low recoil.

The 6.5 Creedmoor is based on the .308 Winchester cartridge, which means it uses a similar case and bullet diameter. However, the 6.5 Creedmoor has a shorter overall length and less powder capacity than the .308 Winchester.

This makes the 6.5 Creedmoor a very efficient cartridge that produces little recoil and muzzle blast.

There are several reasons why the 6.5 Creedmoor has become so popular among target shooters and hunters alike:

1) Accuracy: The 6.5 Creedmoor is an incredibly accurate cartridge, thanks to its tight tolerances and consistent performance at long range.

Many top competitive shooters rely on the 6.. 2) Low Recoil: The 6..3) Versatility: The 6..4) Affordable: The6..

4 Hemi Drive Belt Diagram

Assuming you would like a diagram of how to route a drive belt for a vehicle with a 4 Hemi engine:

1. Locate the crankshaft pulley at the front of the engine. This pulley will have grooves that the drive belt will fit into.

2. There are typically two other pulleys located behind the crankshaft pulley- an idler pulley and a tensioner pulley. The idler pulley keeps the belt tight against the crankshaft while the tensioner adjusts to keep proper tension on the belt so it doesn’t slip off.

3. Route the drive belt around all three of these main Pulleys in a clockwise direction, making sure it fits snugly into each groove as you go along.

4. Once you have routed the belt around all three of these main Pulleys, there may be additional accessory Pulleys that need to be threaded through next (for example, power steering or air conditioning). Again, make sure the belt is seated correctly in each groove as you thread it through until all accessory Pulleys are complete.

How Does the 6

7 Powerstroke fare in towing?

Assuming you are asking about the 2019 Ford F-450 6.7 L Powerstroke V8 diesel:

The short answer is, it does quite well.

The F-450 has a max towing capacity of 37,000 pounds when properly equipped, which is more than enough for most hauling and trailer needs. It should be noted that the F-450 is not the only truck in its class with this much towing power – the Chevrolet Silverado 4500HD and Ram 5500 also have comparable towing capacities. However, what sets the F-450 apart from its competition is its combination of power and fuel economy.

This engine is capable of producing up to 450 horsepower and an impressive 925 lb-ft of torque, while still getting an EPA estimated 20 mpg on the highway (15 mpg city). In terms of raw power and efficiency, there aren’t many trucks that can match the 6.7L Powerstroke V8.

4 Hemi Drive Belt Work

Assuming you would like tips on how to change a drive belt on a 4 Hemi engine:

The drive belt on a 4 Hemi engine is responsible for transferring power from the crankshaft to the accessories. Over time, the drive belt can become worn and may need to be replaced.

Here are some tips on how to change a drive belt on a 4 Hemi engine:

1. Disconnect the negative battery cable.

2. Remove the supercharger pulley and idler pulley.

3. Remove the old drive belt.

4. Install the new drive belt.

5. Reinstall the supercharger pulley and idler pulley.

What are the Benefits of Using a 6

5-inch smartphone?

A 6.5-inch smartphone is a device with a screen that is approximately 6.5 inches in size. This is larger than the average phone, which has a screen size of around 5 inches.

There are several benefits to using a phone with a larger screen, including the following:

1. You can see more content at once: With a larger screen, you can see more of your favorite websites, apps, and photos all at once. This is especially handy if you like to have multiple tabs open when you’re browsing the web or if you tend to use your phone for long periods of time without taking frequent breaks.

2. More space for typing: If you do a lot of typing on your phone (e.g., writing emails or creating documents), then you’ll appreciate the extra space that a 6.5-inch screen provides. With more room to work, you can type faster and make fewer mistakes.

3 .

Improved readability: The enlarged screen also makes text easier to read, whether you’re reading an article or trying to decipher small print on a document or image.

4 Hemi Drive Belt

There are four main types of drive belts: flat, V-belts, timing belts, and serpentine. The belt type will be determined by the engine configuration. Some engines have more than one belt.

For example, a serpentine belt may be used to drive the water pump and alternator, while a timing belt or chain is used to synchronize the camshaft(s) and crankshaft.

The most common type of drive belt is the serpentine belt. Serpentine belts are made of reinforced rubber and can last up to 100,000 miles before they need to be replaced.

They are also less likely to break than other types of belts.

Flat belts were once the most common type of drive belt, but they have largely been replaced by serpentine belts. Flat belts are made of reinforced fabric or rubber and typically last 30-60,000 miles before they need to be replaced.

V-belts are used on some older cars and trucks with carburetors (instead of fuel injection). V-belts are made of reinforced rubber and typically last 20-30,000 miles before they need to be replaced.

Timing belts or chains are found in many newer vehicles (usually manufactured after 1985).

Timing belts typically need to be replaced every 60-90,000 miles; timing chains usually last the lifetime of the vehicle but may stretch over time and eventually need to be replaced .

How Do I Install a 6

4 Hemi in a 2008 Dodge 1500 2wd?

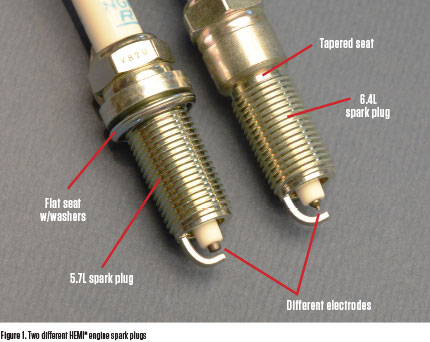

If you’re looking to install a 6.4 Hemi engine in your 2008 Dodge 1500 2wd, there are a few things you’ll need to keep in mind. First, the 6.4 Hemi is a bit wider than the 5.7 Hemi, so you may need to modify your engine bay slightly to accommodate the new engine.

Additionally, the 6.4 Hemi requires an 8-speed automatic transmission, so you’ll need to source one of those as well. Finally, because the 6.4 Hemi is a newer engine, you may need to update your ECU and other electronics to work with the new engine.

Overall, installing a 6.4 Hemi in a 2008 Dodge 1500 2wd is doable, but it will require some modification and updates to make everything work properly together.

4 Hemi Drive Belt

Assuming you would like information on the Chrysler Hemi engine:

The Chrysler Hemi engine, known by the trademarked name FirePower, was produced from 1951 to 1958. hemis were used in a variety of vehicles including the Chrysler New Yorker, Imperial, Windsor, DeSoto Custom and Adventurer.

The original design was created by Chrysler engineer Weslake and first appeared in European cars. American Motors Corporation also used hemis in some of their early models.

The key feature of a hemi engine is its hemispherical combustion chamber.

This allows for better air/fuel mixture swirling which results in more complete combustion and increased power output. The downside to this design is that it is more expensive to produce and requires more maintenance than a traditional engine.

Chrysler did not produce another hemi engine until 2003 when they introduced the 5.7L Hemi V8 for use in their Dodge Ram pickup trucks.

This new generation of Hemi engines featured fuel-saving technology such as variable valve timing and cylinder deactivation which helped improve fuel economy while still providing plenty of power when needed.

How Do I Remove a 6

5 diesel glow plug?

If you have a 6.5 diesel engine, then you know that the glow plugs are responsible for providing heat to the air in the cylinders so that combustion can occur. Without them, your engine will not start properly in cold weather.

So, if one of your glow plugs is damaged or defective, you’ll need to replace it as soon as possible. Here’s how you can do that:

1. First, locate the problem glow plug.

You can do this by removing the spark plug wire from each glow plug and testing them with a multimeter. The defective glow plug will have a higher resistance than the others.

2. Once you’ve found the problem plug, remove it from the engine block using a ratchet and socket (the size will depend on your particular engine).

3. Now, clean out the threads in the engine block where the old glow plug was installed using a tap set (again, the size will depend on your specific engine). This is important because you want to make sure there’s no debris or damage that could prevent the new plug from seating properly.

4. Install the new glow plug into the engine block and tighten it down with a ratchet and socket until it’s snug (but don’t over-tighten).

5. Reconnect the spark plug wire to the new glow plug and repeat steps 1-4 for any other damaged or defective plugs.

4 Hemi Drive Belt

Assuming you would like a blog post discussing the drive belt for a Chrysler Hemi engine:

The drive belt in a Chrysler Hemi engine is responsible for transferring power from the crankshaft to the various accessories that are driven by the engine. These accessories can include the water pump, alternator, power steering pump, and air conditioning compressor.

The drive belt is made up of several different belts that are each responsible for driving a specific accessory.

The main belt that is used to transfer power from the crankshaft to the accessories is called the serpentine belt. The serpentine belt is made up of several smaller belts that are each connected to an individual pulley.

The smaller belts are made of rubber and are reinforced with Kevlar or other similar materials. The serpentine belt is designed to last for the lifetime of the vehicle and does not need to be replaced unless it is damaged or worn out.

If one of the small belts that make up the serpentine belt breaks, it can cause all of the accessories driven by that particularbelt to stop working.

For example, if the water pump pulley broke, thenthe water pump would no longer function and coolant would no longer be circulated throughthe engine. If this happened, it could lead to overheating and damage tothe engine components. That’s why it’s important to have your drivebelt inspected regularly and replaced if necessary.

Conclusion

This blog post provides a detailed diagram of the drive belt for a 6.4 Hemi engine. The diagram shows the various pulleys and belts that make up the system, and labels each component. The post also includes some tips on how to keep the drive belt in good condition, such as checking the tension regularly and replacing any damaged or worn parts.

Read Also: