6.7 Cummins Ticking Noise at Idle: Stop the Noise Now

Hearing a ticking noise from your 6.7 Cummins engine at idle and don’t know what to do? You’re not alone, and ignoring it isn’t an option. In this guide, we’ll cover:

Stay tuned to get to the bottom of that mysterious ticking noise and learn how to silence it for good.

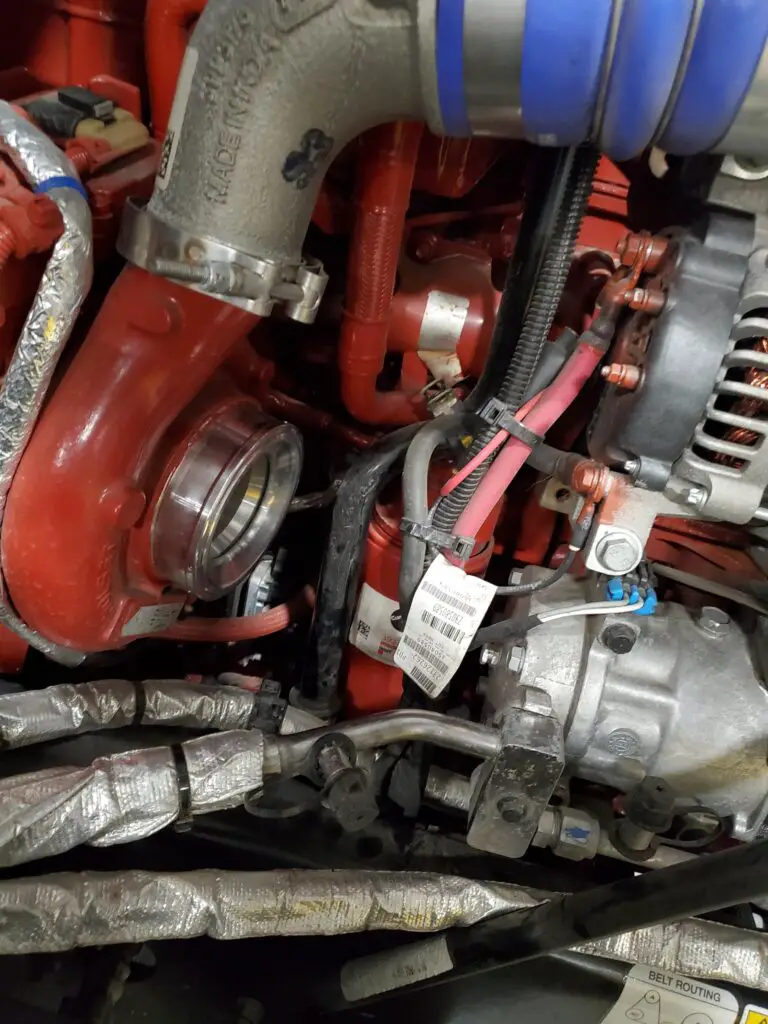

Identifying the Ticking Noise in a 6.7 Cummins Engine

If you’re hearing a ticking noise from your 6.7 Cummins engine at idle, it’s crucial to identify the root cause. The noise you’re hearing could be a warning sign of underlying issues that could escalate if not addressed. Here, we’ll discuss what the ticking noise might sound like and the tools you’ll need to diagnose the issue.

The Ticking Noise at Idle

When we talk about a ticking noise at idle in a 6.7 Cummins engine, we’re generally referring to a rhythmic, metallic sound. It’s a sound that’s most noticeable when the engine is idling but can sometimes be heard during low-speed driving. The noise usually originates from the engine compartment.

Note: If the ticking noise gets louder or changes pitch when you rev the engine, it’s an indication that the issue should be addressed as soon as possible.

Tools Needed for Diagnosis

Before diving into the diagnostic process, make sure you have the right tools at hand. These tools will not only make the process easier but also more accurate.

| Tool | Purpose | Where to Use |

|---|---|---|

| Mechanic’s Stethoscope | Pinpointing noise source | Engine Compartment |

| Oil Dipstick | Checking oil level | Oil reservoir |

| Wrench Set | Tightening loose components | Various parts of the engine |

By taking the time to properly diagnose the ticking noise in your 6.7 Cummins engine, you’ll be better equipped to tackle the issue head-on. Proper identification is the first step toward a reliable and long-lasting solution.

Warning: Incorrect diagnosis can lead to unnecessary repairs. When in doubt, consult a professional mechanic to ensure you’re addressing the real issue.

By following this guide, you’ll not only identify the source of that annoying ticking noise but also take the first critical step toward resolving it. Stay tuned for solutions tailored to each potential cause.

Diagnostic Steps

Determining the cause of a ticking noise in a 6.7 Cummins engine involves several diagnostic steps. These steps are straightforward and require basic tools. Let’s explore each one in detail.

Visual Inspection

The first step in diagnosing a ticking noise is a visual inspection. By looking closely, you might find loose or damaged parts that are the source of the noise.

Note: Turn off the engine and allow it to cool before starting your visual inspection to avoid burns or other injuries.

Procedure:

- Open the Hood: Make sure the engine is cool before you start.

- Check for Loose Components: Look around the engine compartment for loose bolts, brackets, or other parts.

- Inspect the Exhaust Manifold: Check for cracks or leaks, as these can produce ticking sounds.

- Look at the Heat Shields: Ensure they are secure, as loose heat shields can rattle.

Warning: A visual inspection might not reveal all issues. Further diagnosis may be needed if the problem isn’t apparent.

Oil Level Check

The next step involves checking the engine’s oil level. Low oil levels can lead to inadequate lubrication, causing components like lifters to make a ticking noise.

Procedure:

- Locate the Oil Dipstick: Usually marked with a bright handle for easy identification.

- Remove and Wipe Clean: Pull out the dipstick, wipe it clean, and reinsert it.

- Check Oil Level: Remove the dipstick again to see if the oil level is between the “min” and “max” marks.

Remember: If the oil level is low, add the recommended type of oil for your 6.7 Cummins engine. Refer to your owner’s manual for oil specifications.

Using a Mechanic’s Stethoscope

If the visual inspection and oil level check don’t reveal the source of the ticking noise, using a mechanic’s stethoscope can help you pinpoint it.

Procedure:

- Prepare the Engine: Start the engine and let it idle.

- Safety First: Wear safety goggles and gloves.

- Use the Stethoscope: Carefully place the stethoscope probe on different parts of the engine to isolate the source of the ticking noise.

| Area to Probe | Possible Noise Source |

|---|---|

| Near the Lifters | Lifter Noise |

| Around Injectors | Injector Noise |

| Exhaust Manifold | Cracks or leaks |

| Valvetrain Components | Camshaft, valves, etc. |

By diligently following these diagnostic steps, you’ll have a clearer understanding of where the ticking noise in your 6.7 Cummins engine is coming from. This sets the stage for effective troubleshooting and repair.

Potential Causes of Ticking Noise at Idle in 6.7 Cummins

Understanding the root cause of a ticking noise in a 6.7 Cummins engine is crucial for effective troubleshooting. In this part, we’ll explore various potential causes, their characteristics, and how they can impact your engine’s performance.

Lifter Noise

Lifter noise typically sounds like a tapping or ticking that comes from the top end of the engine. It can be particularly loud when the engine is cold and may lessen as the engine warms up.

Characteristics of Lifter Noise:

- Tapping or ticking sound

- More prominent when the engine is cold

- Originates from the top end of the engine

How It Impacts Engine Performance:

- This can lead to inefficient valve operation

- This may result in reduced engine power and fuel efficiency

Warning: Ignoring persistent lifter noise can lead to more severe engine damage over time.

Injector Noise

In diesel engines like the 6.7 Cummins, injector noise is often considered normal. However, excessive injector noise might be a cause for concern.

Commonality in Diesel Engines:

- A slight ticking or clicking sound is often normal

- More noticeable at idle or low speeds

When to Be Concerned:

- When the noise becomes loud or changes pitch

- If accompanied by other symptoms like poor engine performance

Loose or Damaged Components

Loose or damaged components can often be a source of ticking or rattling noises. Common culprits include exhaust manifolds, heat shields, and even loose bolts.

Typical Components That Can Cause Noise:

- Exhaust manifold

- Heat shields

- Loose bolts or screws

How to Spot Them:

- Visual inspection

- Listen for noise near suspected areas

Remember: Tightening loose components can often quickly resolve the issue.

Valve Train Noise

Valve train components like the camshaft, rocker arms, and valves can also be sources of ticking noises.

Description and Characteristics:

- High-pitched ticking or clicking

- Usually constant and increases with engine RPM

Risks Involved:

- This can lead to valve damage

- Potential for more severe engine issues if not addressed

Low Oil Level

Low oil level is a common cause of ticking noises, as it can lead to inadequate lubrication of engine components.

How Low Oil Contributes to the Noise:

- Causes poor lubrication

- This may result in metal-on-metal contact, causing the ticking noise

Importance of Correct Oil Level:

- Ensures proper lubrication and cooling of engine components

- Prevents premature wear and tear

Note: Always maintain the correct oil level as specified in your vehicle’s manual to avoid engine noises and damage.

Understanding these potential causes is your first line of defense against ticking noises in your 6.7 Cummins engine. Proper diagnosis can save you time and money, setting the stage for effective solutions.

Solutions to Address 6.7 Cummins Ticking Noise at Idle

Once you’ve pinpointed the cause of the ticking noise, you can start exploring various solutions. Here we will outline methods to tackle each identified cause, ranging from simple fixes to more complex procedures that may require professional assistance.

Solving Lifter Noise

Lifter noise can be distressing, but there are a couple of ways to manage it.

Oil Additives: Special oil additives can lubricate worn lifters and reduce noise. However, this is often a temporary solution.

Replacement Options: For more severe cases, replacing the lifters may be necessary. This is a complex task usually best left to professionals.

Managing Injector Noise

While injector noise is common in diesel engines, elevated noise levels may require attention.

Cleaning Methods: Fuel injector cleaners can dissolve deposits that may be contributing to the noise. These are often added to the fuel tank during a fill-up.

Injector Replacement: If the noise persists after cleaning, replacing the injectors may be the next step. Consult a mechanic to confirm this is the appropriate solution.

Fixing Loose or Damaged Components

If the ticking noise is due to loose or damaged components, the fix might be straightforward.

Tightening Procedures: Using a wrench set, you can tighten loose bolts and brackets. Just ensure the engine is cool before you start to avoid injury.

Component Replacement: If tightening doesn’t resolve the issue, some components may need to be replaced.

Handling Valve Train Noise

Addressing valve train noise can be a bit complicated and may require a professional touch.

Adjustment Techniques: Minor adjustments can sometimes resolve the issue, but incorrect adjustments could exacerbate the problem.

When to Consult Professionals: If you’re not comfortable making these adjustments yourself, or if they don’t resolve the issue, it’s time to consult a qualified mechanic.

Addressing Low Oil Level

A low oil level can contribute to ticking noises and is one of the easiest issues to resolve.

Proper Filling Methods: Simply top up your engine oil, making sure you’re using the type recommended in your owner’s manual.

Oil Change Recommendations: If the oil is not just low but also dirty, an oil change might be in order.

By addressing the cause of your 6.7 Cummins engine’s ticking noise at idle, you’ll be better positioned to resolve the issue effectively.

Ticking Noise at Idle In Different Models

Preventive Measures for 6.7 Cummins Ticking Noise at Idle

Prevention is often better than cure, especially when it comes to vehicle maintenance. By taking a few precautionary steps, you can significantly reduce the likelihood of experiencing a ticking noise in your 6.7 Cummins engine at idle. Here are some key preventive measures.

Regular Maintenance Checks

Routine maintenance checks can go a long way in preventing not just ticking noises but also other potential issues with your engine.

- Engine Inspection: Regularly inspect your engine for loose or damaged components.

- Listen During Startup: Pay attention to any unusual sounds when you start your engine.

Regular maintenance checks will often catch small issues before they turn into bigger, more costly problems.

Importance of Periodic Oil Changes

One of the simplest yet most effective ways to prevent ticking noises is to ensure your engine oil is changed regularly.

- Follow Manufacturer Guidelines: Always follow the oil change intervals specified in your owner’s manual.

- Use Quality Oil: Opt for high-quality oil that meets the specifications for your vehicle.

Keeping your engine well-lubricated can prevent many issues, including those annoying ticking noises at idle.

Being Attentive to Abnormal Engine Sounds

Your vehicle often communicates its health through sounds. Being attentive can be your first line of defense against mechanical issues.

- Pay Attention at Idle: Take a moment to listen to your engine while it’s idling; this is often when ticking noises first become noticeable.

- Don’t Ignore Changes: If you notice a new or louder noise, it’s worth investigating further.

Being proactive and attentive to your engine’s needs will not only help you prevent ticking noises but can also extend the lifespan of your 6.7 Cummins engine.

6.7 Cummins Ticking Noise at Startup

We have seen the same issue at Idle, but are you noticing the ticking noise when starting the engine and feeling confused?

This is caused by the exhaust gas recirculation (EGR) system, and that’s considered normal. The EGR system recirculates a small amount of exhaust gas back into the combustion chamber to help reduce emissions.

When the engine is first started, the EGR system is purging itself of any accumulated exhaust gas. This purge process can cause a ticking noise that lasts for a few seconds before disappearing. So if you hear a ticking noise coming from your 6.7-liter Cummins engine at startup, don’t be alarmed.

However, I have found someone online who said that if the engine gets cold, and tries to start the engine, it can produce some ticking noises. even those people also consider this thing normally because the problem will go once the engine gets heated.

- You Can See: How Long Does it Take to Delete a 6.7 Cummins

6.7 Cummins Ticking When Warm

Some people noticed that their 6.7 Cummins is ticking when the engine is warm. this is not a common issue but there is a chance to face it in the future.

I have found a person who faced the same issue with his engine. the engine produces a ticking noise once the engine gets heated.

That guy got a solution by reading a solution from an expert person and the solution was:

When you face the issue, you will need to do something with your lash of the geartrain and pulses of the engine.

For this, you can pop the gear off the pump shaft turn the shaft a few degrees, and tighten it. this might help you to get rid of this ticking issue when the engine gets warmed.

Conclusion

So there you have it! Now you’re equipped with the know-how to tackle that pesky ticking noise in your 6.7 Cummins engine at idle. From identifying the noise to finding a fix, and even preventing it in the future, you’ve got it all covered. Safe driving and quieter idles await you!