12V 5.9 Cummins Timing Marks

Proper timing is crucial for the engine’s performance and longevity. Incorrect timing can cause a variety of problems, such as poor fuel economy, reduced power, and even engine damage.

This guide will provide a complete overview of the timing marks on a 12V 5.9 Cummins engine and will cover the process of setting the timing and troubleshooting.

How to Set the Timing on a 12V 5.9 Cummins Engine

The 12V 5.9 Cummins engine has two timing marks:

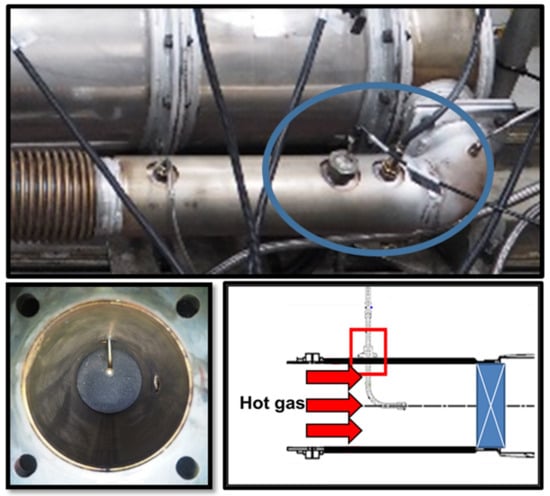

- Top Dead Center (TDC): This mark is located on the harmonic balancer and indicates the position of the piston at the top of its stroke.

- Injection Pump Timing Mark: This mark is located on the injection pump and indicates the position of the pump at which fuel is injected into the cylinders.

To set the timing on a 12V 5.9 Cummins engine, you will need to use a timing light. Here is a more detailed guide:

- Connect the timing light to the engine. There are two ways to do this:

- Using the spark plug wires: Connect the timing light’s inductive clamp to one of the spark plug wires.

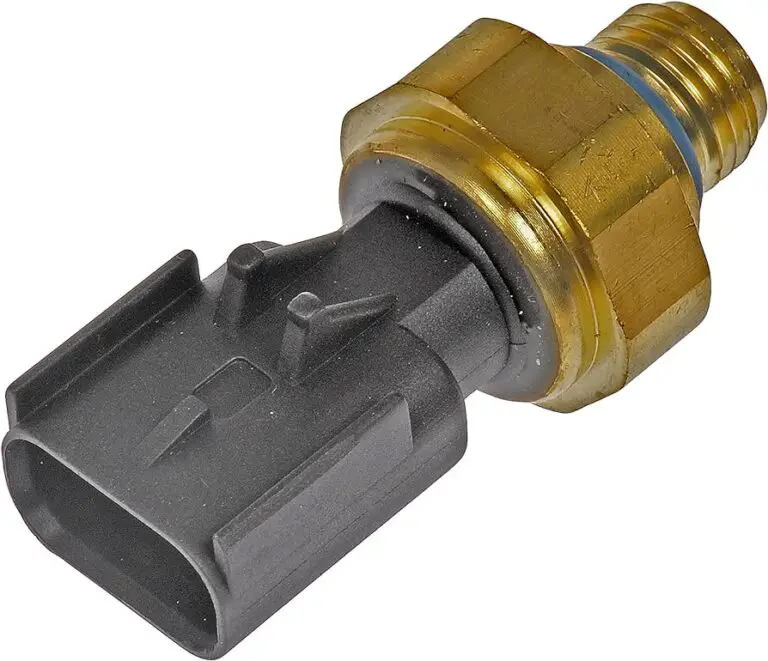

- Using the timing light adapter: Connect the timing light adapter to the injection pump port. Then, connect the timing light to the timing light adapter.

- Set the timing light to the correct setting for your engine. The correct timing setting for your engine will be listed in your vehicle’s owner’s manual.

- Start the engine and let it warm up to operating temperature. This is usually around 180 degrees Fahrenheit.

- Shine the timing light at the timing marks on the harmonic balancer and injection pump. The timing marks on the harmonic balancer are two small lines that are located near the top of the balancer. The timing mark on the injection pump is a small dot that is located on the front of the pump.

- Adjust the injection pump until the timing marks are aligned. There are two ways to adjust the injection pump:

- Loosen the injection pump mounting bolts and rotate the pump. Be careful not to overtighten the mounting bolts when you are finished.

- Use a timing gear puller to adjust the timing gear on the injection pump. This is a more difficult method, but it is also more accurate.

- Once the timing marks are aligned, tighten the injection pump mounting bolts and turn off the engine.

4 Additional tips for setting the timing on a 12V 5.9 Cummins engine

Here are some additional tips for setting the timing on a 12V 5.9 Cummins engine:

- Make sure that the engine is at operating temperature before setting the timing.

- Use a timing light that is designed for diesel engines.

- Be careful not to overtighten the injection pump mounting bolts.

- Recheck the timing after you have tightened the injection pump mounting bolts.

Troubleshooting Tips

Here are some common problems that can occur when setting the timing on a 12V 5.9 Cummins engine and how to fix them:

Problem: The timing marks are not aligned.

Solution:

- Check the following:

- Make sure that the engine is at operating temperature.

- Make sure that the timing light is set to the correct setting for your engine.

- Make sure that the timing marks are clean.

- If the timing marks are still not aligned, you will need to adjust the injection pump.

- If you are unsure how to adjust the injection pump, consult a qualified mechanic.

Problem: The engine is running rough after you have set the timing.

Solution:

- Check the following:

- Make sure that the injection pump mounting bolts are tightened.

- Make sure that the timing marks are aligned.

- If the engine is still running rough, consult a qualified mechanic.

Problem: The engine is smoking after you have set the timing.

Solution:

- Check the following:

- Make sure that the injection pump is properly adjusted.

- Make sure that the fuel injectors are not leaking.

- If the engine is still smoking, consult a qualified mechanic.

What are the timing marks on a 12V 5.9 Cummins engine?

The timing marks on a 12V 5.9 Cummins engine are two small lines that are located on the harmonic

What tools do I need to set the timing on a 12V 5.9 Cummins engine?

You will need a timing light, wrenches, screwdrivers, a feeler gauge, and a clean rag to set the timing on a 12V 5.9 Cummins engine.

How often should I set the timing on a 12V 5.9 Cummins engine?

It is recommended to set the timing on a 12V 5.9 Cummins engine every 10,000-15,000 miles, or more often if the engine is used in dusty or dirty conditions.

Can I set the timing on a 12V 5.9 Cummins engine myself?

Yes, you can set the timing on a 12V 5.9 Cummins engine yourself. However, it is important to follow the instructions carefully and to make sure that you have the correct tools and supplies.

You Can Read Also:

- 2Nd Gen Cummins Interior Swap

- Ram 2500 Trailer Light Fuse

- Ram 2500 Battery Saver Mode

- Ram 2500 6.4 Hemi 6 Speed Vs 8 Speed

- Ram 2500 35S No Lift

Conclusion:

Setting the timing on a 12V 5.9 Cummins engine is an important task that can help to improve the engine’s performance and fuel economy. If you are unsure about any aspect of setting the timing on a 12V 5.9 Cummins engine, it is always best to consult with a qualified mechanic.