Cummins ISM Oil Pump Location: Complete Guide & Troubleshooting Tips

When your Cummins ISM engine starts making that telltale ticking sound that keeps you up at night, understanding exactly where to find the oil pump can save you thousands in repairs and countless hours of frustration. After working on these engines for over 20 years, I can tell you that locating the Cummins ISM oil pump is the first critical step in diagnosing and fixing oil pressure problems. Whether you’re hearing unusual noises, seeing warning lights, or just being proactive about maintenance, this guide will walk you through everything you need to know about this vital component.

Understanding the Cummins ISM Engine

Before we dive into the specifics of the oil pump location, let’s get familiar with what makes the ISM such a workhorse in the trucking industry.

The Cummins ISM engine was introduced in 1998 as an evolution of the M11 engine platform and remained in production until 2010. With displacements ranging from 10.8 to 11.0 liters (661-672 cubic inches), these inline-six diesel engines became the backbone of medium and heavy-duty trucking applications across North America.

| Specification | Details |

|---|---|

| Production Years | 1998-2010 |

| Displacement | 10.8-11.0L (661-672 cu in) |

| Cylinder Configuration | Inline 6 |

| Horsepower Range | 280-500 HP |

| Torque Range | 900-1,550 lb-ft |

| Common Applications | Class 8 trucks, fire apparatus, motorhomes, buses |

What made the ISM special was its balance of power, reliability, and serviceability. I’ve personally seen these engines rack up well over a million miles with just basic maintenance. But when oil system problems develop, they can quickly turn your reliable workhorse into an expensive paperweight.

The ISM Engine Oil System: Overview

Before we pinpoint the oil pump location, let’s understand how the entire lubrication system works in the ISM.

The oil system in the Cummins ISM is a pressurized circuit that delivers lubricating oil to all critical engine components. The system begins at the oil pan, where the oil pump draws oil through a pickup tube and screen, pressurizes it, and sends it through the oil filter, oil cooler, and then throughout the engine via a network of galleries and passages.

Key Components of the ISM Oil System:

- Oil pump – Creates pressure and flow

- Oil pickup tube and screen – Draws oil from the pan

- Oil filter module – Removes contaminants

- Oil cooler – Regulates oil temperature

- Main oil galleries – Distribute oil to components

- Pressure relief valve – Prevents excessive pressure

- Oil pressure sensor – Monitors system pressure

- Various check valves – Control oil flow direction

Why oil pressure matters so much: Unlike older mechanical engines, the ISM relies on proper oil pressure not just for lubrication but also for critical functions like actuating the fuel injectors. When oil pressure drops, engine performance, fuel economy, and emissions all suffer before physical damage occurs.

Cummins ISM Oil Pump: Function and Design

The oil pump is the heart of the lubrication system. On the ISM, Cummins uses a robust gear-type pump design that’s engineered for longevity and consistent performance.

How the ISM Oil Pump Works:

The pump consists of two meshing gears enclosed in a housing. As the gears rotate:

- Oil is drawn into the inlet side as gear teeth separate

- Oil is carried around the periphery between the gear teeth and housing

- Oil is forced out the outlet as gear teeth mesh together

- Precise clearances between components create pressure

Unlike some engines that use variable displacement pumps, the ISM uses a fixed-displacement design. This simplicity contributes to its legendary reliability but also means that oil pressure is directly related to engine RPM — the faster the engine runs, the higher the pressure (within limits set by the relief valve).

From the trenches: In my experience rebuilding dozens of these engines, the oil pump itself rarely fails catastrophically. When it does have issues, they typically develop gradually, showing symptoms like declining oil pressure at idle before complete failure occurs.

Cummins ISM Oil Pump Location – Detailed Guide

Now for what you came here for — the exact location of the oil pump in the Cummins ISM engine.

The oil pump on the Cummins ISM is located at the front of the engine, behind the front cover and timing gears. More specifically, it’s mounted to the front of the engine block and driven directly by the gear train.

To find it:

- Start at the front of the engine (fan side)

- Remove the front cover (after proper disassembly procedures)

- The oil pump is positioned behind the timing gears, typically on the lower right portion of the timing gear housing

- It’s bolted to the engine block with the pickup tube extending down into the oil pan

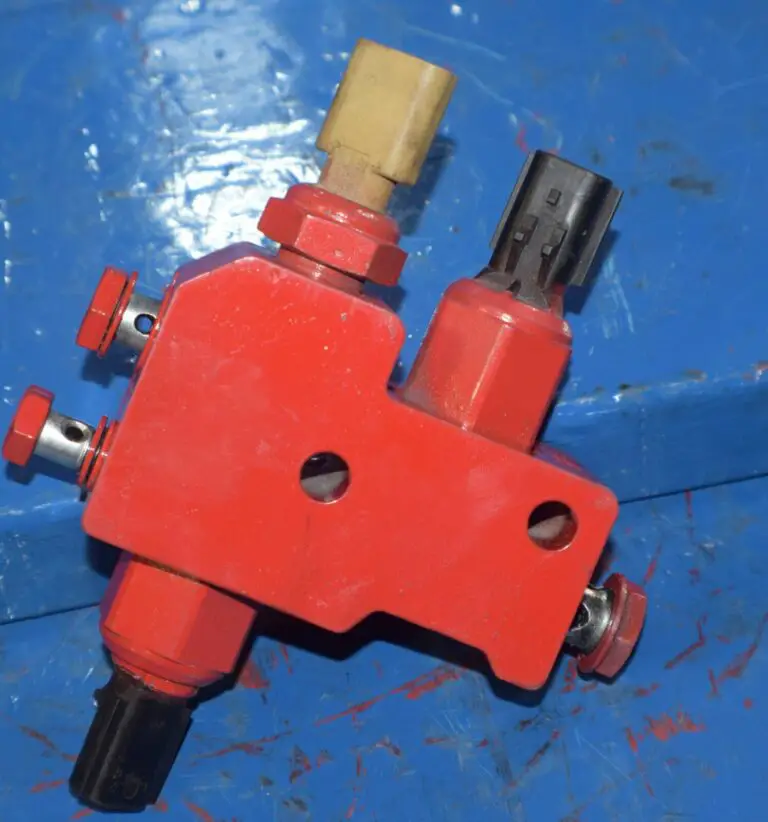

Visual identification markers: The pump assembly is typically aluminum with a distinctive gear-driven design and will have oil passages connecting to the main block galleys. It’s secured by multiple bolts and will have a pickup tube extending downward.

Variations Between Model Years

While the general location remained consistent throughout production, there were some design changes:

- Early ISM models (1998-2002): Used a slightly larger pump housing

- Mid-production (2003-2007): Refined pump design with improved sealing

- Late models (2008-2010): Further enhancements to improve durability

Pro tip from experience: When trying to identify which version you have, the engine serial number is the most reliable indicator. Attempting to determine the variant by visual inspection alone can be misleading due to potential previous repairs or component replacements.

Accessing the Oil Pump

Getting to the oil pump in the ISM is a significant undertaking that requires substantial disassembly. This isn’t a roadside repair — it’s a shop job that requires planning and proper equipment.

Tools You’ll Need:

- Complete socket and wrench sets (both standard and metric)

- Torque wrenches (both inch-pound and foot-pound ranges)

- Front cover puller tool set

- Timing gear puller

- Gasket scraper

- Digital camera or smartphone (for documenting disassembly)

- Engine barring tool

- Service manual or detailed repair instructions

Step-by-Step Access Procedure:

- Preparation

- Drain engine oil

- Remove radiator and fan assembly

- Disconnect all necessary electrical connectors and hoses

- Remove accessories (A/C compressor, alternator, etc.)

- Major Component Removal

- Remove vibration damper (harmonic balancer)

- Remove front engine mount (in most installations)

- Remove front cover bolts and front cover

- Timing Gear Access

- Remove timing gear cover

- Note timing marks and gear alignment

- Remove necessary timing gears for access

- Oil Pump Removal

- Remove bolts securing the oil pump to the block

- Carefully extract the pump and pickup tube assembly

Important safety note: Always follow proper lifting and support procedures when working on heavy engine components. Never rely solely on a jack — always use jack stands or proper support equipment.

Accessibility Variations By Truck Model

The level of difficulty in accessing the oil pump varies significantly depending on the chassis the ISM is installed in:

- Freightliner Century/Columbia: Generally offers the best access after cab removal

- International/Navistar: Often requires more component disassembly due to tighter packaging

- Kenworth/Peterbilt: Access varies by model but typically requires significant front-end disassembly

- Motorhome applications: Often the most challenging due to limited service access

Real-world insight: In many truck applications, a partial cab lift or complete cab removal makes the job significantly easier. While this sounds extreme, it’s often faster and less expensive than attempting to work in the confined space available with the cab in place.

Common Oil Pump Issues in the ISM Engine

How do you know if your oil pressure problems are actually coming from the pump? Here are the most common issues I’ve encountered:

Typical Symptoms of Oil Pump Problems:

- Low oil pressure warning light or gauge readings

- Fluctuating oil pressure, especially at idle

- Increased engine noise (ticking or chattering)

- Metal particles in oil (indicator of pump or bearing wear)

- Engine overheating (oil helps cool internal components)

- Power loss (particularly if oil pressure affects injector actuation)

Common Failure Modes:

- Worn pump gears or housing

- Results in reduced pressure due to internal leakage

- Usually develops gradually over hundreds of thousands of miles

- Pickup tube/screen issues

- Clogged screen restricts flow

- Cracked pickup tube allows air to enter system

- Often causes intermittent pressure problems

- Pressure relief valve problems

- Stuck open: consistently low pressure

- Stuck closed: excessively high pressure

- Spring fatigue: pressure fluctuations

- Drive gear issues

- Damaged teeth can cause erratic operation

- Shaft wear can reduce efficiency

Diagnosing the real culprit: Before condemning the oil pump, verify that the issue isn’t elsewhere in the system. In my experience, about 30% of “oil pump problems” are actually due to worn engine bearings, faulty oil pressure sensors, or clogged oil passages.

Oil Pump Removal and Replacement Procedures

Once you’ve accessed the oil pump and determined it needs replacement, here’s how to proceed:

Inspection Before Replacement:

- Check the pickup tube and screen

- Look for cracks or damage

- Ensure the screen is clean and intact

- Verify proper mounting and sealing

- Examine the pump housing

- Look for scoring, cracks, or excessive wear

- Check mounting surfaces for damage

- Inspect gear teeth for chipping or excessive wear

- Test the pressure relief valve

- Ensure it moves freely

- Check for broken or weakened spring

- Look for debris that could affect operation

Installation Procedure:

- Preparation

- Clean all mating surfaces thoroughly

- Apply appropriate sealant if specified

- Lubricate pump gears with clean engine oil

- Installation

- Carefully align the pump with its drive mechanism

- Install mounting bolts hand-tight initially

- Torque bolts to specification in the correct sequence

- Verify the pickup tube is properly positioned in the oil pan

- Reassembly

- Reinstall timing gears, maintaining proper timing marks

- Replace front cover with new gasket

- Reinstall all removed components

- Refill with proper oil type and quantity

Critical torque specifications:

- Oil pump mounting bolts: 18-22 ft-lbs (typical)

- Front cover bolts: 18-22 ft-lbs (typical)

- Harmonic balancer bolt: 150-160 ft-lbs (typical)

Pro tip from the repair bay: Always rotate the engine by hand (using a barring tool) through at least two complete revolutions after reassembly before attempting to start it. This ensures there are no binding issues and helps pre-lubricate components.

Technical Specifications and Service Information

For those who want the nitty-gritty details, here are some specific technical specs for the ISM oil pump:

OEM Part Information:

- Cummins part numbers vary by model year and revision

- Standard oil pressure specifications:

- Idle (600-800 RPM): 10 PSI minimum

- Rated speed: 30-70 PSI (depending on temperature and wear)

Aftermarket Options:

When replacing the oil pump, you have several options:

- Genuine Cummins – Most expensive but guaranteed fit and quality

- Major aftermarket brands (PAI, Interstate-McBee) – Good quality, slightly lower cost

- Economy rebuilds – Lowest cost but potentially shorter lifespan

My recommendation from experience: This is not a component to skimp on. The labor to replace it far exceeds the cost difference between economy and quality parts. I’ve seen too many economy pumps fail within 100,000 miles to recommend them for any application except absolute emergencies.

Oil System Maintenance Best Practices

The best solution to oil pump problems is preventing them in the first place. Here’s how:

Maintenance Schedule for Maximum Reliability:

- Oil changes: Every 15,000-25,000 miles for normal service (less for severe duty)

- Oil filter: Replace with every oil change, using quality filters

- Oil analysis: Recommended every 25,000 miles to track engine health

- Pressure checks: Record oil pressure readings regularly to spot trends

- Cold weather operation: Allow proper warm-up time before applying load

Oil Selection Guidelines:

The ISM was designed when 15W-40 diesel oil was the standard, but modern formulations offer improvements:

- Conventional 15W-40: Acceptable baseline for moderate climates

- 5W-40 or 10W-30 synthetic: Better cold flow characteristics

- CK-4 specification: Latest standard offering improved protection

Real-world observation: I’ve consistently seen better oil pressure maintenance and longer component life in fleets that use premium synthetic oils and quality filters, even with extended drain intervals. The additional cost is easily offset by reduced wear and downtime.

Real-World Experiences and Case Studies

Let me share a couple of actual scenarios I’ve encountered that illustrate common ISM oil pump issues:

Case Study 1: The Intermittent Pressure Drop

A fleet customer brought in a 2006 Freightliner with an ISM that had intermittent low oil pressure warnings, but only after extended highway driving. The dealership had already replaced the oil pressure sensor twice with no improvement.

The culprit: A hairline crack in the oil pickup tube that would open up as the engine and oil heated to full operating temperature, allowing air to enter the system. This caused oil pressure drops only under specific conditions, making diagnosis challenging.

Case Study 2: The Startup Rattle

An owner-operator complained about excessive valve train noise on startup that would disappear after about 10 seconds. The noise gradually increased over several months until it persisted even after warm-up.

The cause: Worn oil pump gears had reduced pump efficiency, meaning it took longer to build proper oil pressure at startup. The decreased volume also meant that at operating temperature, the thinner oil couldn’t maintain proper pressure. A pump replacement solved the issue completely.

The lesson learned: Oil pump issues often provide early warning signs before catastrophic failure. Addressing them promptly can prevent more extensive damage.

Comparison with Oil Pump Locations in Other Cummins Engines

How does the ISM’s oil pump location compare to other popular Cummins engines?

ISM vs. ISX:

The bigger brother to the ISM, the ISX has a significantly different design:

- ISX pump is driven off the gear train but located lower in the front housing

- Typically easier to access than the ISM pump

- Similar design philosophy but larger capacity

ISM vs. ISB:

The smaller ISB takes a completely different approach:

- ISB pump is mounted externally on the block

- Can often be replaced without major disassembly

- Driven by the gear train, but much more accessible

From my experience: If you maintain multiple Cummins engine types, don’t assume service procedures are similar. The ISM oil pump is among the most labor-intensive to access compared to other Cummins highway engines.

Advanced Considerations for Fleet Maintenance

For fleet managers and serious owner-operators, here are some advanced strategies:

Predictive Maintenance Approaches:

- Oil analysis trending

- Track metal content to identify wear patterns

- Monitor viscosity changes that could affect pump performance

- Look for contamination that might damage the pump

- Pressure data logging

- Some modern diagnostic tools can log oil pressure over time

- Identify subtle pressure drops before they trigger warnings

- Correlate with operating conditions for better diagnosis

- Vibration analysis

- Advanced fleets can use vibration monitoring to detect early pump problems

- Particularly useful for critical applications where downtime is extremely costly

Cost-benefit insight: For a typical highway tractor, the all-in cost to replace an ISM oil pump (parts and labor) ranges from $2,500-$4,000 at current rates. Preventative replacement during a scheduled overhaul adds only a fraction of this cost, making it cheap insurance for high-mileage engines.

Troubleshooting Beyond the Oil Pump

When diagnosing oil pressure issues, don’t immediately assume the pump is at fault. Here are other common causes I’ve encountered:

Common Oil Pressure Problem Sources:

- Oil viscosity issues

- Incorrect oil weight for conditions

- Oil breakdown due to extended drain intervals

- Fuel dilution thinning the oil

- Engine bearing wear

- Main and rod bearing clearances affect system pressure

- Often mistaken for pump problems

- Requires more extensive repairs than pump replacement

- Clogged oil passages

- Sludge buildup in galleys

- Debris from previous failures

- Can create localized pressure problems

- Sensor and gauge issues

- Faulty sensors giving false readings

- Wiring problems affecting gauge operation

- Can be verified with a mechanical pressure test

Diagnostic approach: I always recommend installing a mechanical oil pressure gauge temporarily to verify electronic readings before condemning expensive components. This simple step has saved countless unnecessary repairs.

Conclusion

Understanding the Cummins ISM oil pump location and function is essential knowledge for anyone operating or maintaining these dependable engines. While accessing the pump requires significant disassembly, knowing the proper procedures and what to look for can save tremendous time and expense.

Remember these key points:

- The oil pump is located at the front of the engine behind the timing gears

- Access requires substantial disassembly in most cases

- Many oil pressure issues are caused by problems other than the pump itself

- Preventative maintenance is far less expensive than emergency repairs

- Quality replacement parts are worth the additional cost

Whether you’re a fleet maintenance manager, independent mechanic, or an owner-operator handling your own service, I hope this guide helps you maintain your Cummins ISM for many hundreds of thousands of trouble-free miles.

Frequently Asked Questions

How long should a Cummins ISM oil pump last?

In my experience, with proper maintenance, the oil pump typically lasts 500,000-750,000 miles before efficiency begins to decline noticeably. However, I’ve seen pumps still functioning adequately at over 1 million miles in well-maintained engines.

Will a bad oil pump throw a check engine light?

Not directly. The ISM doesn’t monitor the pump itself, but it does monitor oil pressure. Low oil pressure will trigger a warning lamp and, in severe cases, may put the engine into a protective derate mode. Modern electronic engines may record fault codes related to oil pressure, but not specifically to the pump.

Can I replace just the oil pump without removing the timing gears?

Unfortunately, no. The ISM design requires removal of at least some of the timing gears to access the oil pump mounting bolts. Attempting shortcuts typically results in improper installation or damage to components.

How much does it cost to replace an ISM oil pump?

At current rates (as of 2025), expect to pay:

- Parts: $350-$800 depending on OEM vs. aftermarket

- Labor: $2,000-$3,500 depending on shop rates and specific installation

- Total: $2,350-$4,300 for a complete professional replacement

Is it worth upgrading to a high-volume pump when replacing the original?

For stock applications, no. The standard pump is adequately sized for the engine’s needs. However, if the engine has been modified for higher output or has developed increased bearing clearances from wear, a high-volume pump might be beneficial. Consult with a Cummins specialist for your specific situation.

Can an oil pump failure cause catastrophic engine damage?

Absolutely. If oil pressure drops significantly or is lost entirely, major engine components can suffer rapid and catastrophic damage. Main bearings, connecting rod bearings, and camshaft bearings are particularly vulnerable. Complete pressure loss can destroy an engine in less than a minute at operating RPM.

How do I know if I should replace the oil pump during an in-frame overhaul?

I recommend always replacing the oil pump during an in-frame overhaul for these reasons:

- The labor to access it is already being performed

- The incremental cost is relatively small compared to the overall job

- Starting a freshly rebuilt engine with an unknown-condition pump is an unnecessary risk

- The likelihood of pump wear correlating with engine wear is high